Pack alignment apparatus and methods using linear motor

a linear motor and alignment apparatus technology, applied in the field of wrapping stacks of sheetlike products, can solve the problems of increasing the difficulty of maintaining the squareness of the stack and the accuracy of the stack along the stack travel path, and the shrinkage of the wrapping process and the wrapping arrangement,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

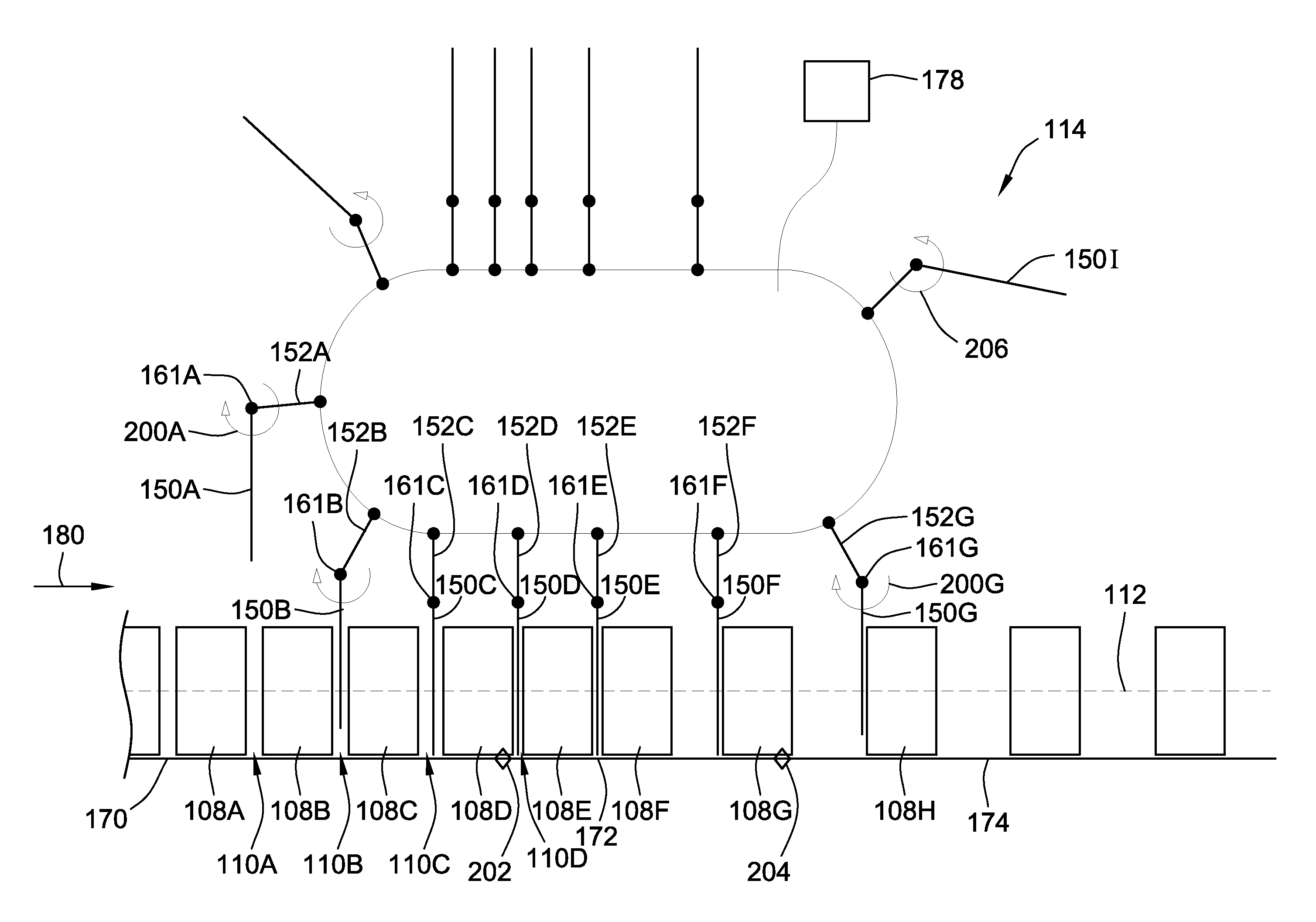

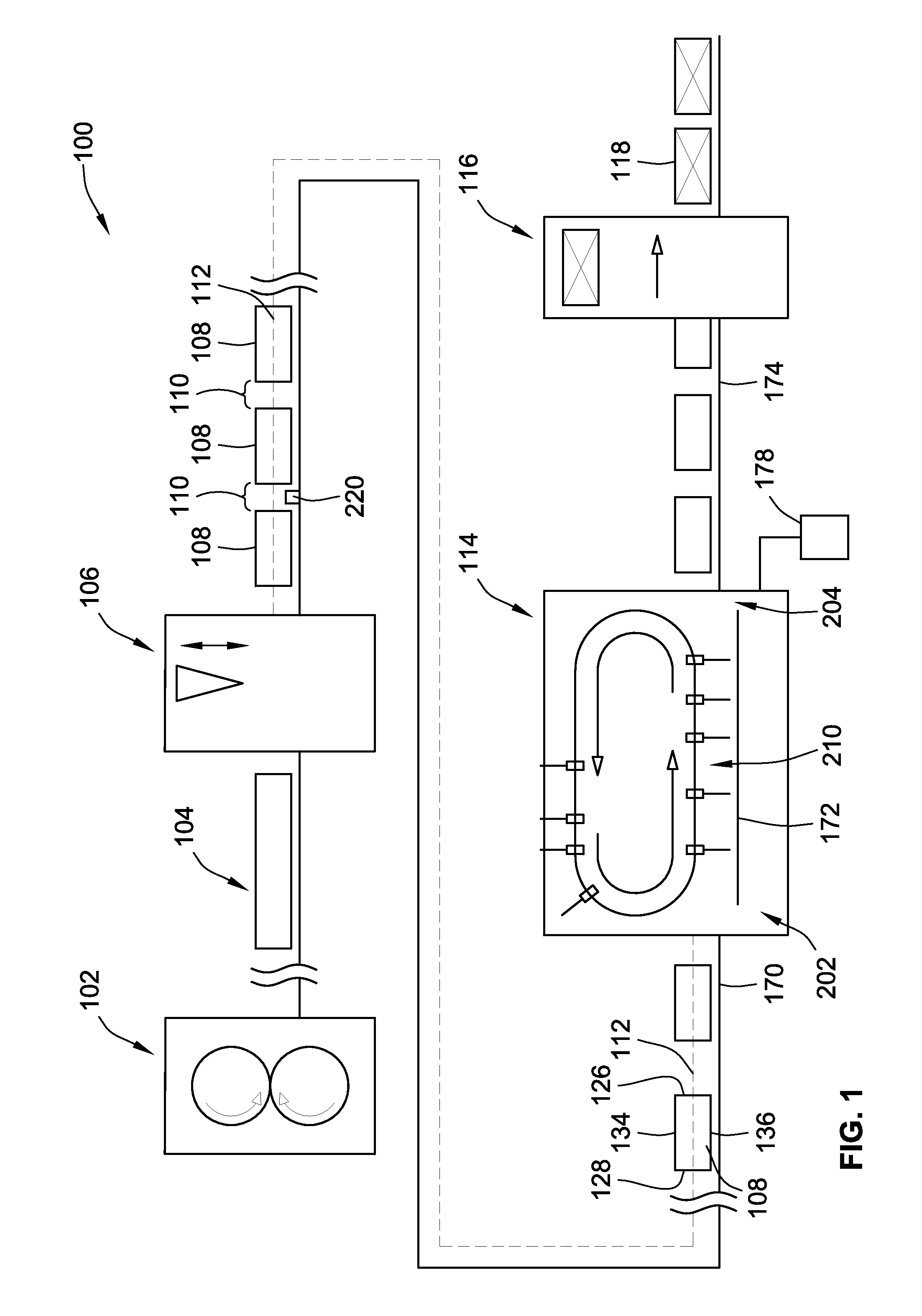

[0060]FIG. 1 is a schematic illustration of a pack forming system 100 according to an embodiment of the present invention. The pack forming system 100 is configured to form and then wrap stacks of sheet-like product such as napkins or facial tissue to form packs of sheet-like product. Typically, the pack forming system 100 will receive a web of material and convert the web of material into the packs of sheet-like product.

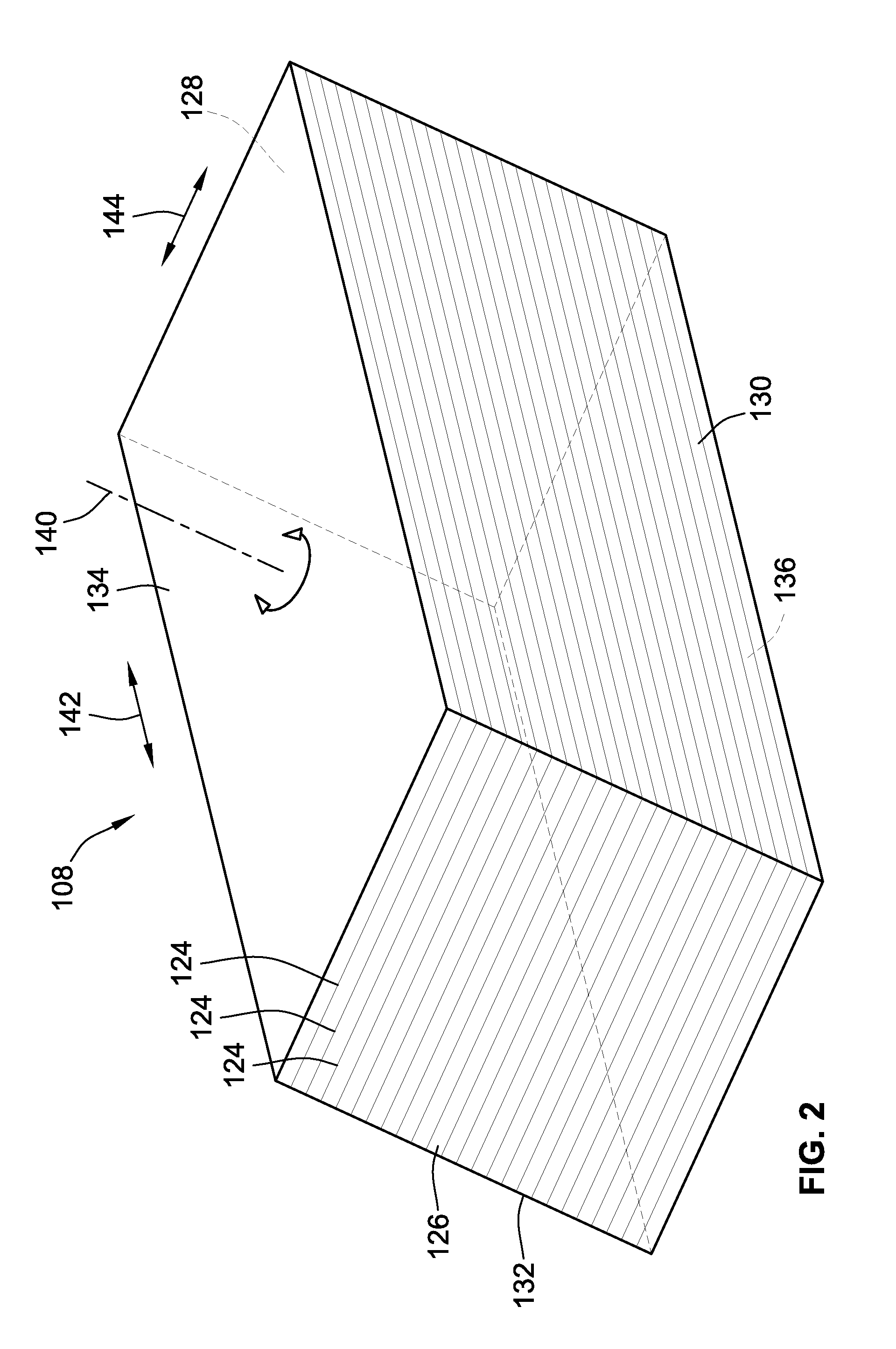

[0061]The illustrated pack forming system 100 includes a folding arrangement 102 that receives a continuous web of material and cuts the web into individual sheets and stacks the sheets to form logs 104. The sheets within the logs 104 may be folded any number of times. Further, adjacent sheets in the logs may be interfolded or merely in a stacked configuration and not interfolded. Preferably, adjacent sheets are vertically stacked. However, embodiments of the invention are not so limited and in some embodiments, the sheets may be vertically oriented such that the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com