Hole arrangement of liners of a combustion chamber of a gas turbine engine with low combustion dynamics and emissions

a gas turbine engine and combustion chamber technology, applied in the direction of machines/engines, mechanical equipment, lighting and heating apparatus, etc., can solve the problems of promoting combustion instabilities, and achieve the effect of reducing combustion instabilities and lowering emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

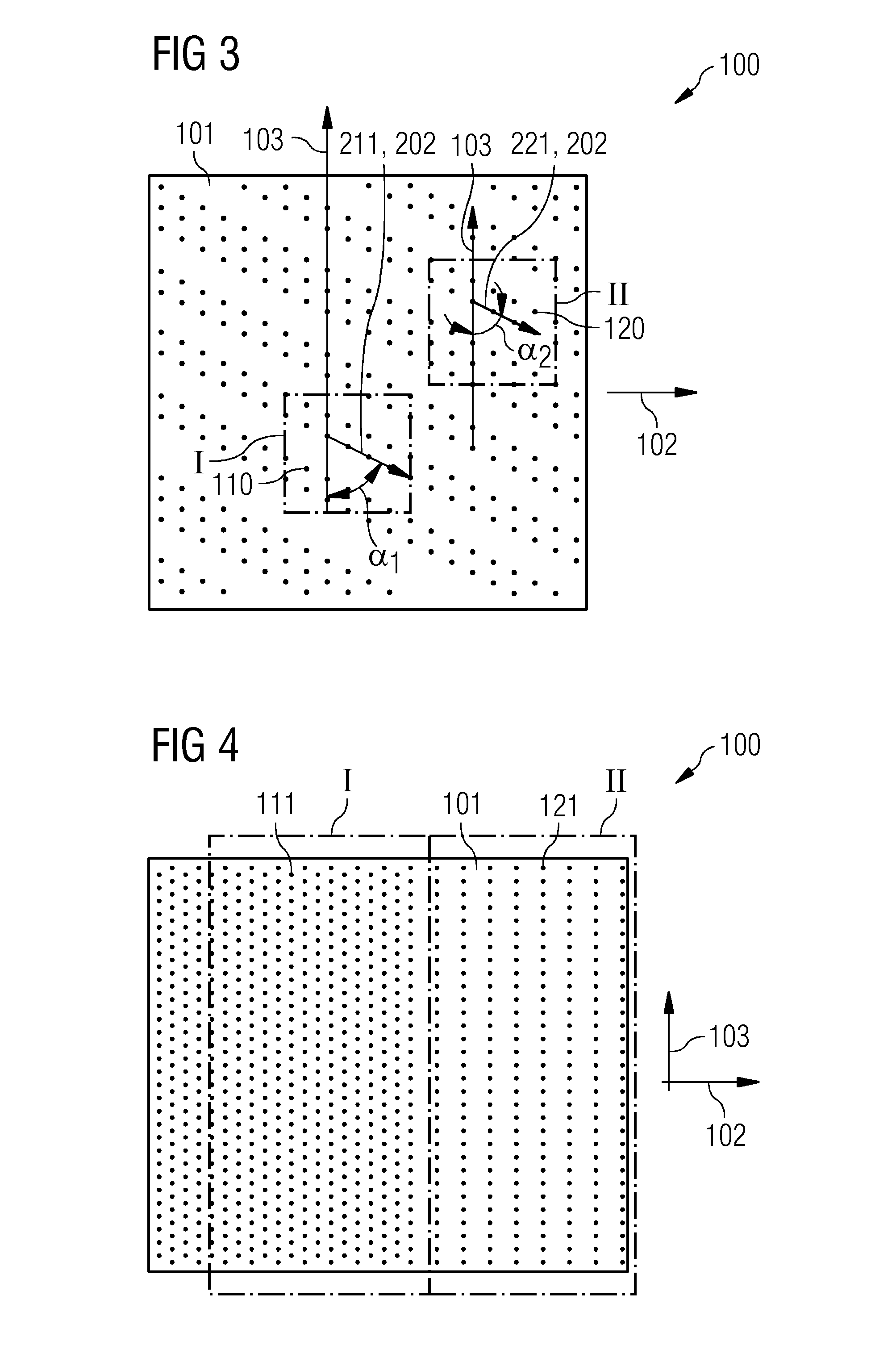

[0042]The illustrations in the drawings are schematical. It is noted that in different figures, similar or identical elements are provided with the same reference signs.

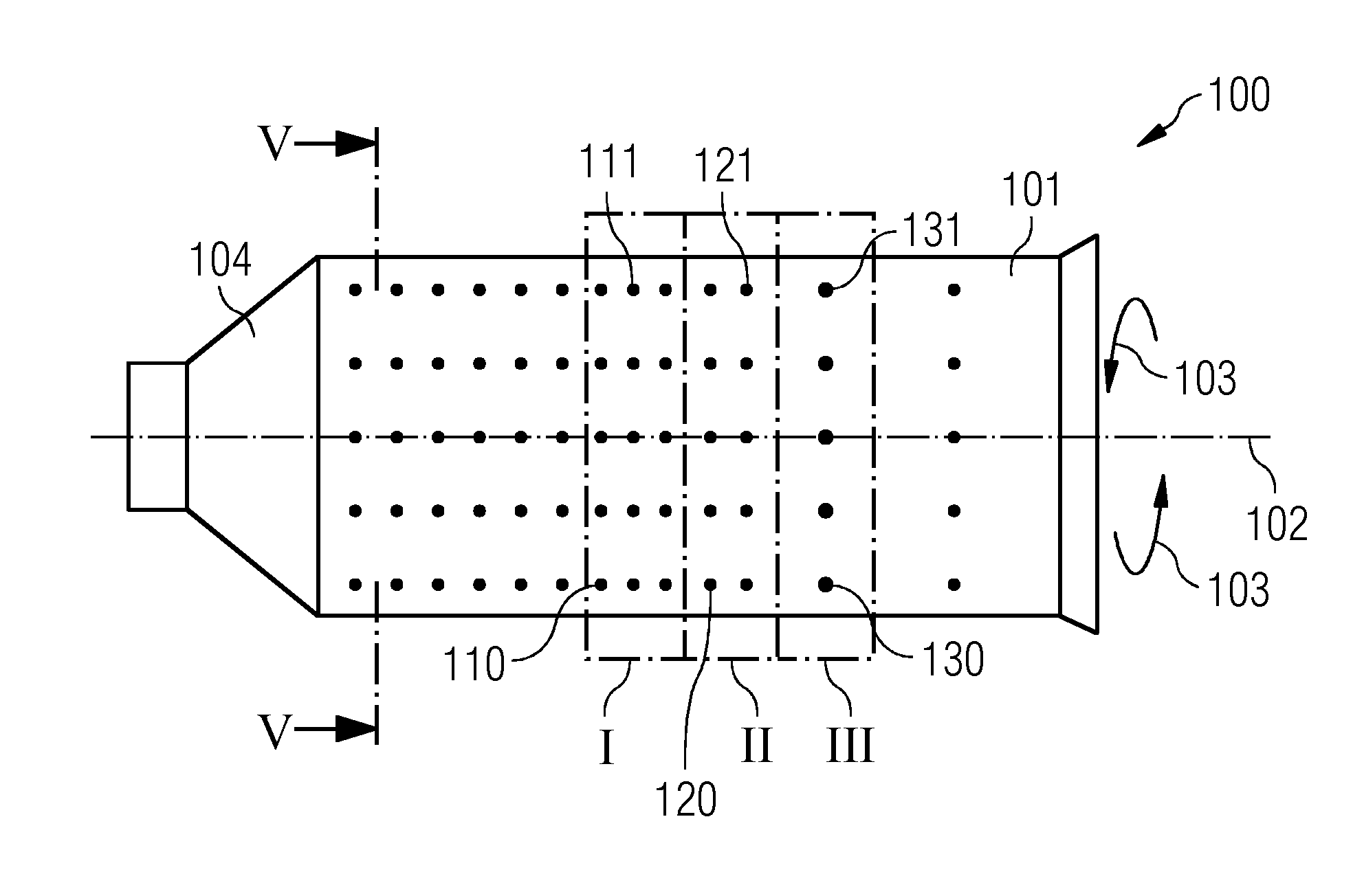

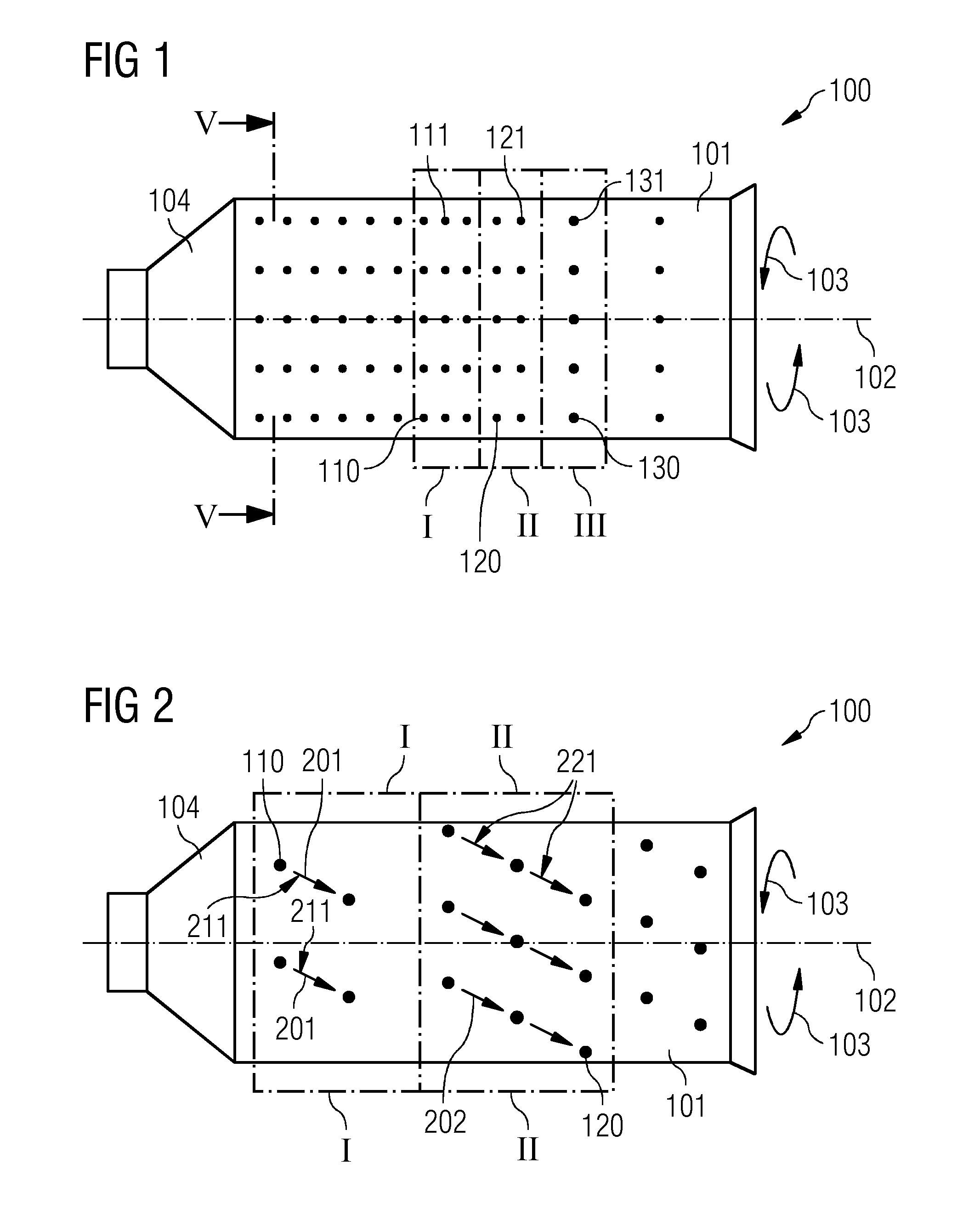

[0043]FIG. 1 shows a housing for a combustion chamber 100 for a gas turbine. The housing comprises a wall element 101 which comprises a first hole arrangement I and a second hole arrangement II. The first hole arrangement I comprises first holes 110 through which first holes 110 fluid is streamable. The first hole arrangement I comprises a first areal density of the first holes 110.

[0044]The second hole arrangement II comprises second holes 120 through which second holes 120 fluid is streamable. The second hole arrangement II comprises a second areal density of the second holes 120.

[0045]The first areal density differs from the second areal density. That is that the amount of first holes 110 per area unit differs from the amount of second holes 120 per area unit. In other words, the first holes 110 are distributed wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com