Methods and systems for indicating water at an oxygen sensor based on sensor heater power consumption

An oxygen sensor, power consumption technology, used in charging systems, testing of machine/structural components, instruments, etc., to solve problems such as inaccurate adjustment of spark timing or other combustion parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

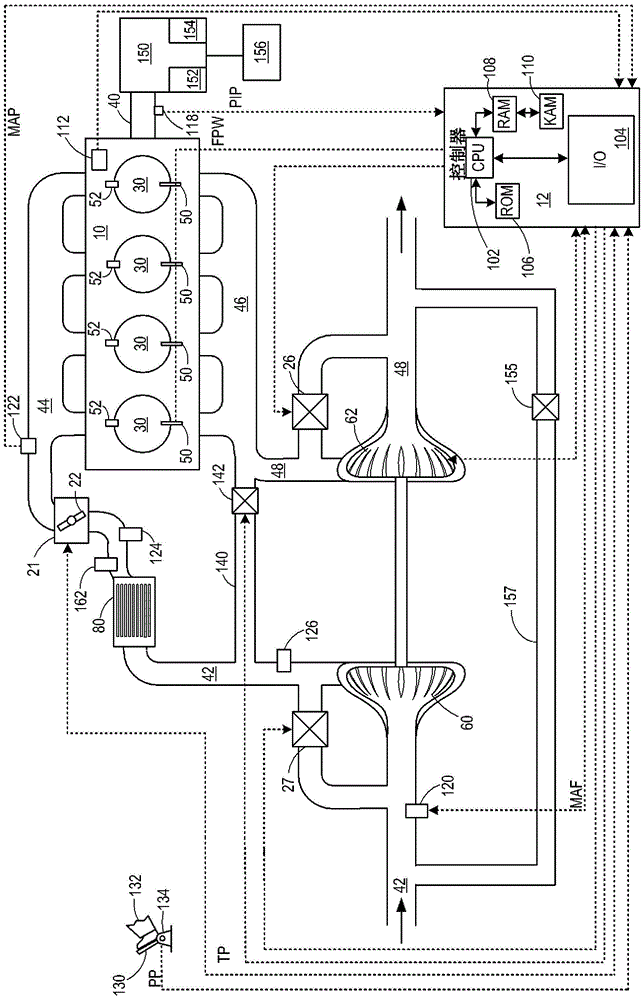

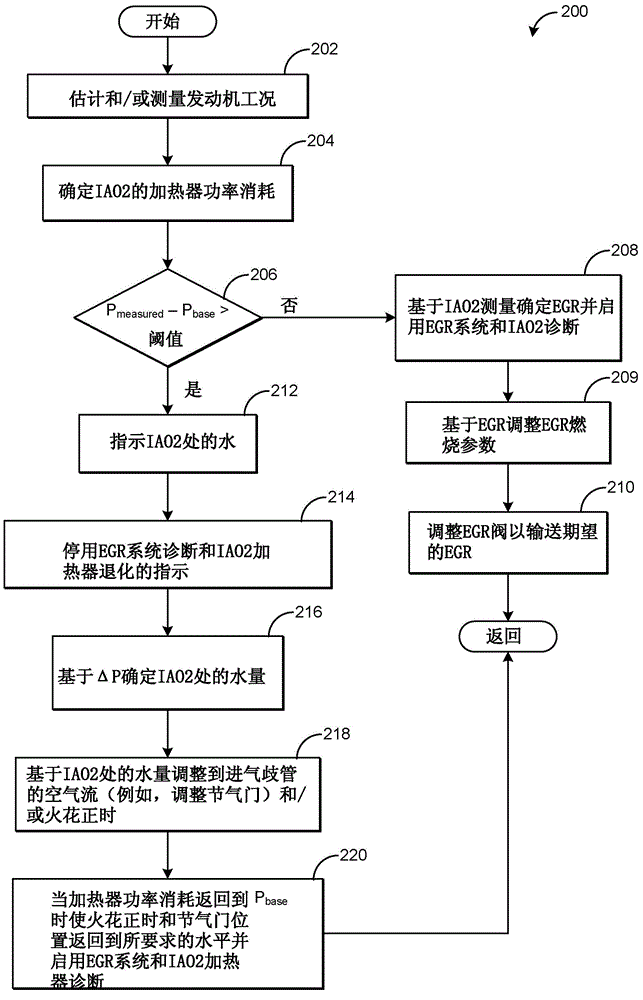

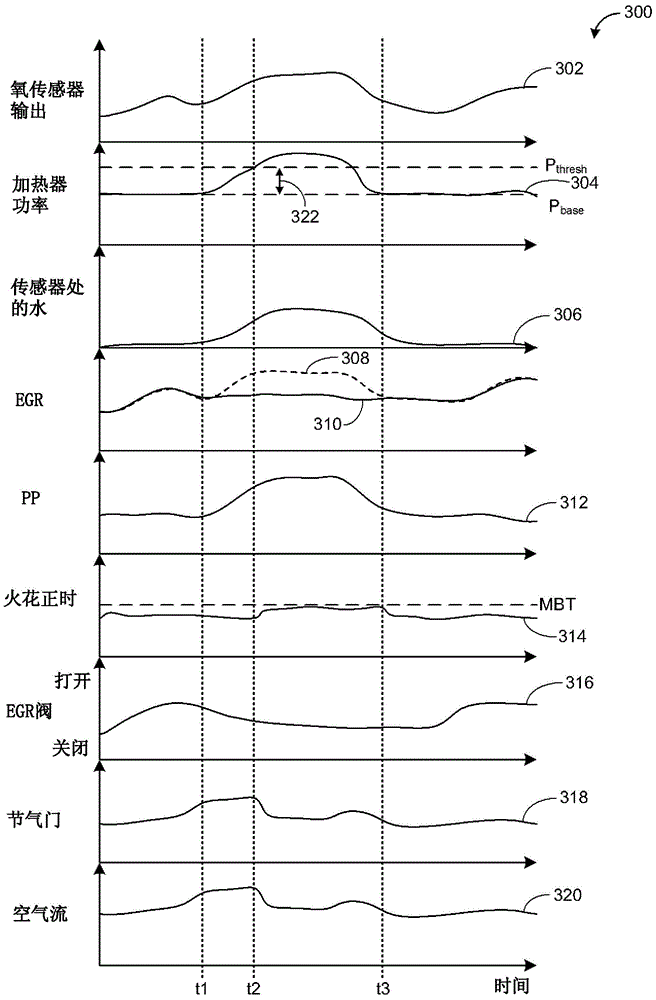

[0009] The following description relates to systems and methods for indicating water at an oxygen sensor based on power consumption of a heating element of the oxygen sensor. Specifically, oxygen sensors may be provided in engine systems such as figure 1 engine system) in the engine intake downstream of the charge air cooler (CAC). Accordingly, the oxygen sensor may be referred to herein as an intake oxygen sensor (IAO2). When water (eg, water droplets) contacts the IAO2, the power consumption of the heating element (eg, heater) of the IAO2 may increase in order to maintain the set point temperature of the IAO2. Accordingly, water at IAO2 may be indicated when power consumption increases by a threshold amount above a baseline power consumption level. figure 2 A method for adjusting engine operation based on power consumption of the IAO2 heating element is shown. Specifically, the engine controller may adjust engine operating parameters and / or disable engine diagnostics in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com