Method for producing heavy oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

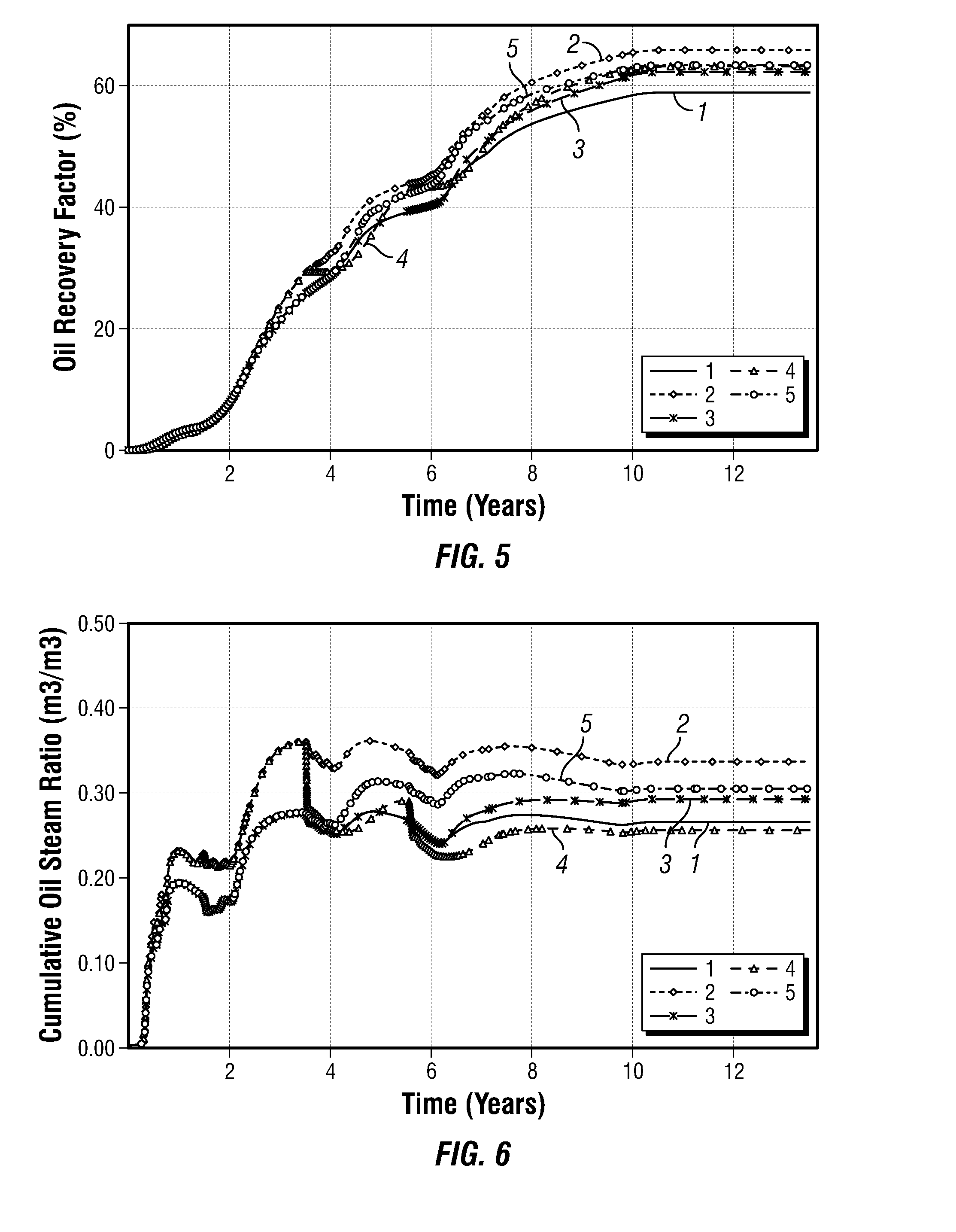

[0032]An alternative of the present invention was modeled, along with some comparative examples. An element of symmetry model representing an inverted seven spot pattern with vertical wells was created to simulate different operational scenarios using the CMG STARS simulator. The CMG STARS simulator is a commercially available oil reservoir simulator available from Computer Modeling Group Ltd., 200, 1824 Crowchild Trail NW, Calgary, Alberta, T2M 3Y7, Canada. Geological and fluid properties selected were typical of the Peace River area, in Alberta, Canada. Five schemes were modeled and in each scheme, all wells were initially operated in a CSS mode for a number of cycles, and then the well in the center was used as a steam injection well while the other wells were operated as producers in a vertical steam drive mode. The five schemes were as follows:

[0033]1. Four CSS cycles, followed by a steam drive with no solvent

[0034]2. Four CSS cycles with solvent co-injected, followed by steam ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap