Up-drawing continuous casting apparatus and up-drawing continuous casting method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

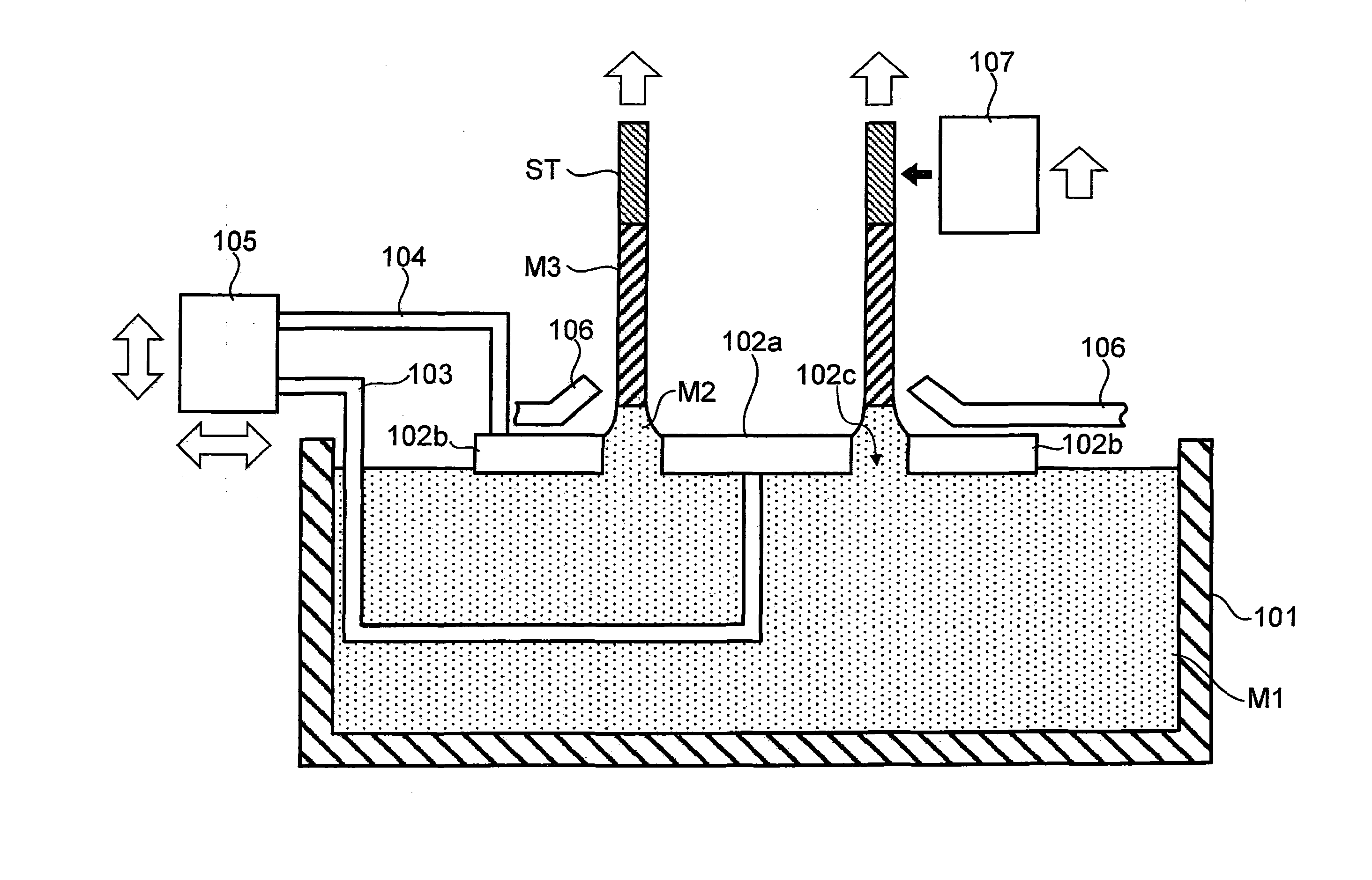

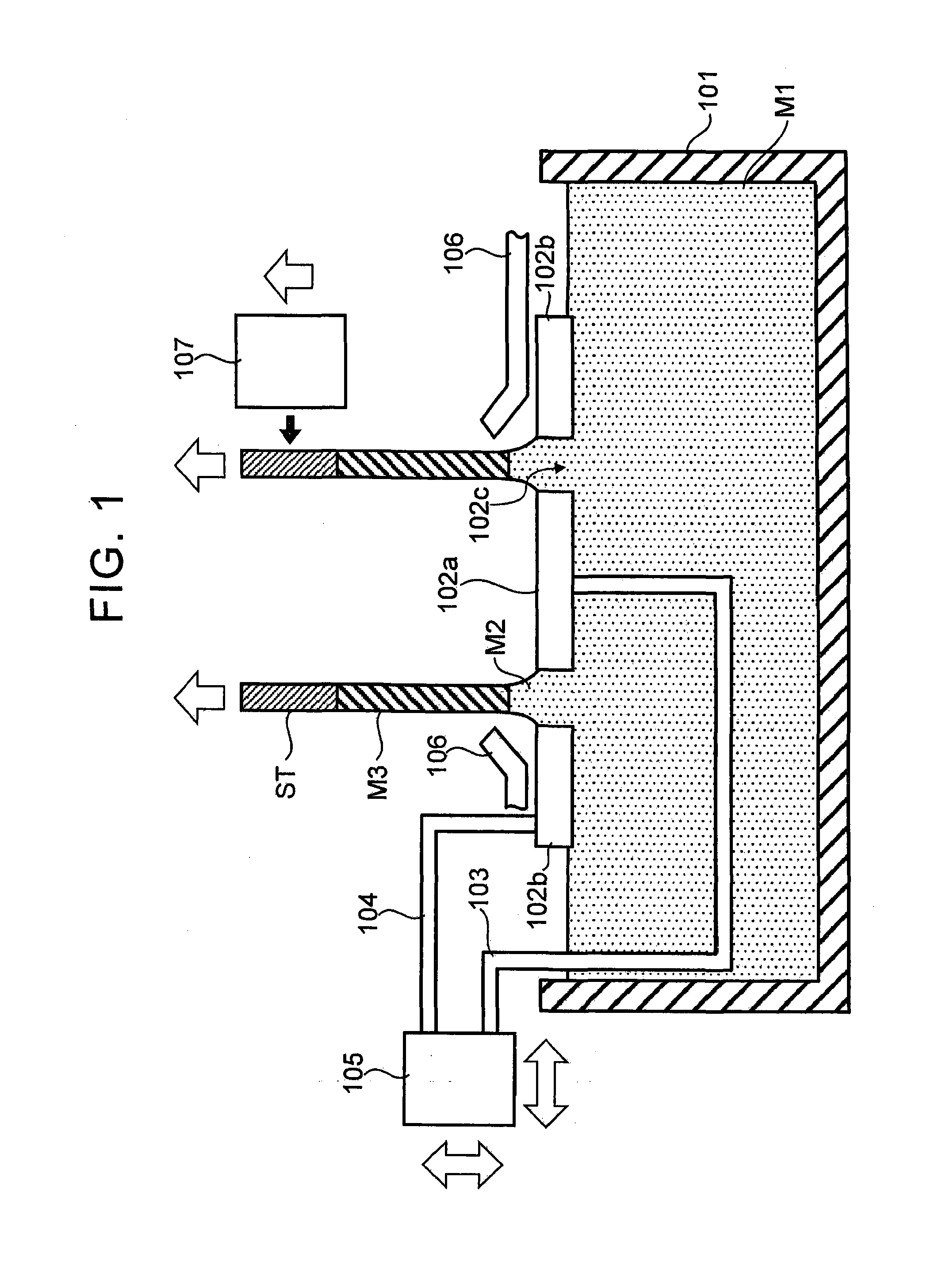

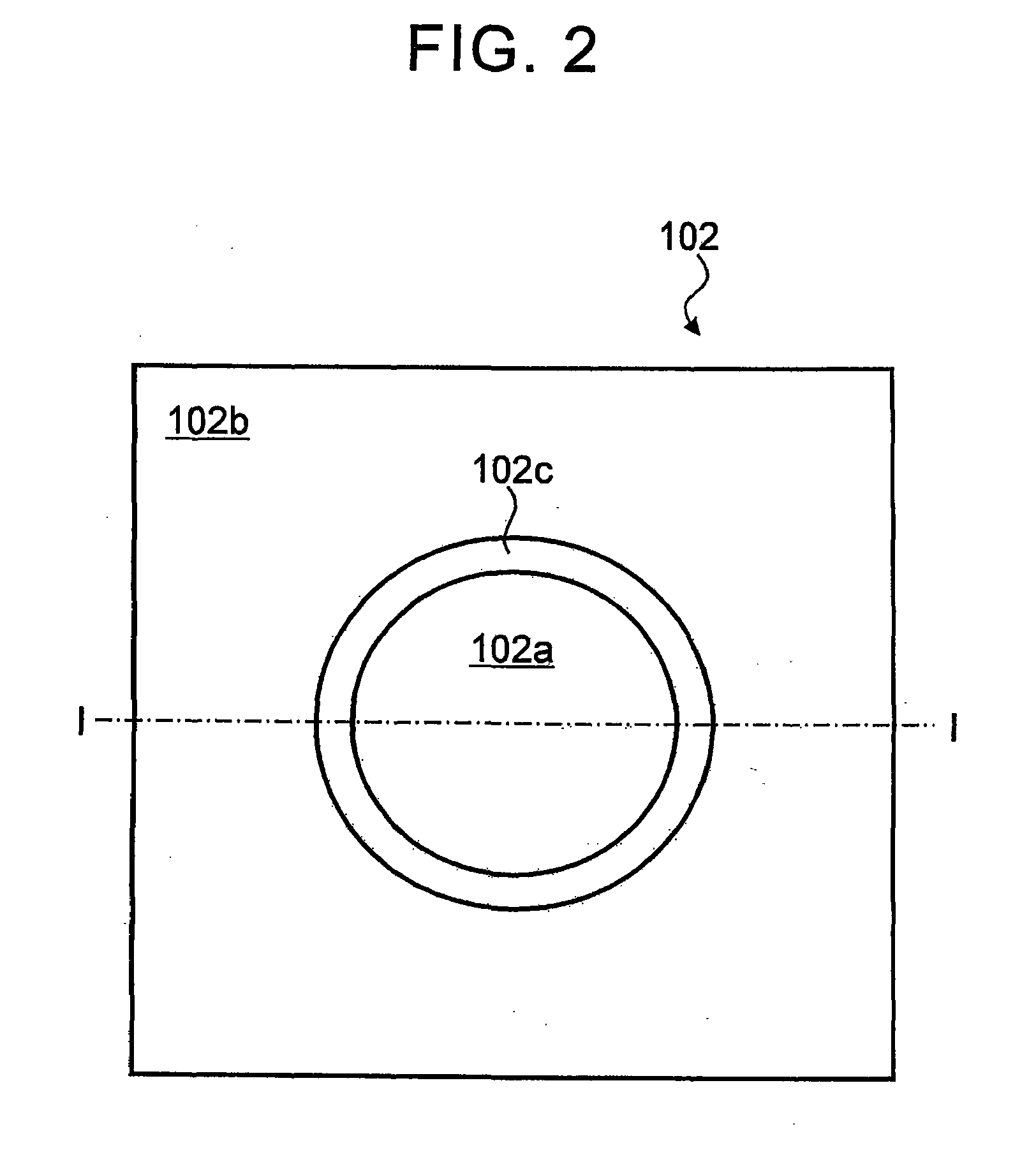

[0036]A free casting apparatus (up-drawing continuous casting apparatus) in accordance with a first embodiment will first be described with reference to FIG. 1. FIG. 1 is a cross-sectional view of the free casting apparatus in accordance with the first embodiment. As shown in FIG. 1, the free casting apparatus in accordance with the first embodiment includes a molten metal holding furnace 101, an inner shape determining member 102a, an outer shape determining member 102b, support rods 103, 104, an actuator 105, a cooling gas nozzle 106, and an impact imparting portion 107.

[0037]The molten metal holding furnace 101 houses molten metal M1 such as aluminum or its alloy and keeps the molten metal at a prescribed temperature. In an example of FIG. 1, because the molten metal holding furnace 101 is not refilled with molten metal during the casting, a surface of the molten metal M1 moves down as the casting progresses. On the other hand, the molten metal holding furnace 101 may constantly ...

second embodiment

[0057]A free casting apparatus in accordance with a second embodiment will next be described with reference to FIG. 5. FIG. 5 is a cross-sectional view of the free casting apparatus in accordance with the second embodiment. The free casting apparatus shown in FIG. 5 includes an oscillator 107a as an impact imparting portion when compared to the free casting apparatus shown in FIG. 1. Other configurations of the free casting apparatus shown in FIG. 5 are the same as the free casting apparatus shown in FIG. 1, and descriptions thereof will be omitted.

[0058]The oscillator 107a finely oscillates in a constant period, thereby imparting fine impacts to the starter ST in constant periods. Accordingly, discontinuous shapes are finely formed at constant intervals on the surface of the casting M3. In other words, fine protrusions and recesses are formed on the surface of the casting M3. This enables improvements in design and heat dissipation of the casting M3.

[0059]Further, the oscillator 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com