Water-spraying toilet

a toilet and water pump technology, applied in the field of washrooms, can solve the problems of not easy to get into the drain, and achieve the effects of reducing workload, easy to get into the drain, and difficult or costly to maintain the hygiene conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

specific embodiments

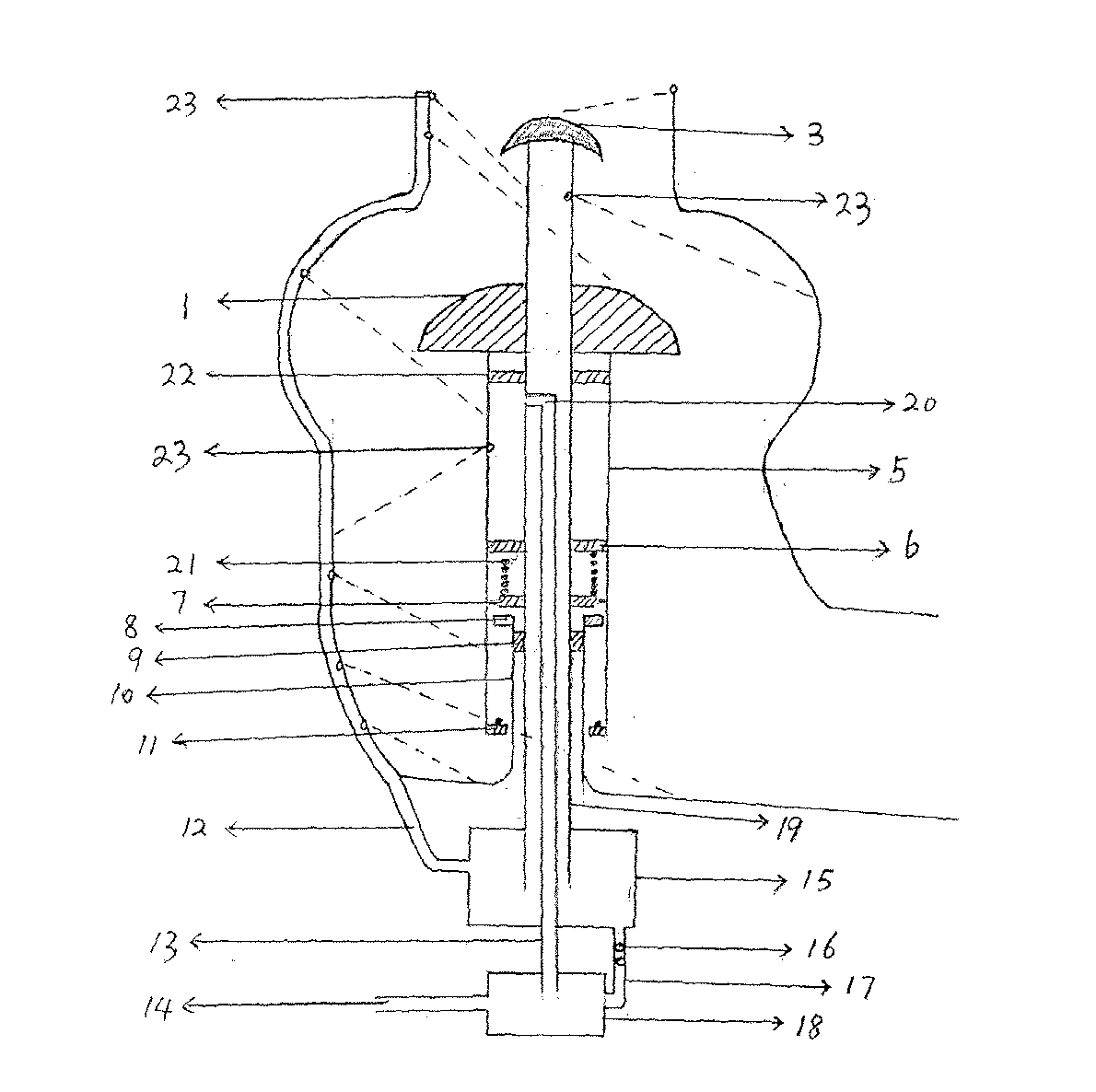

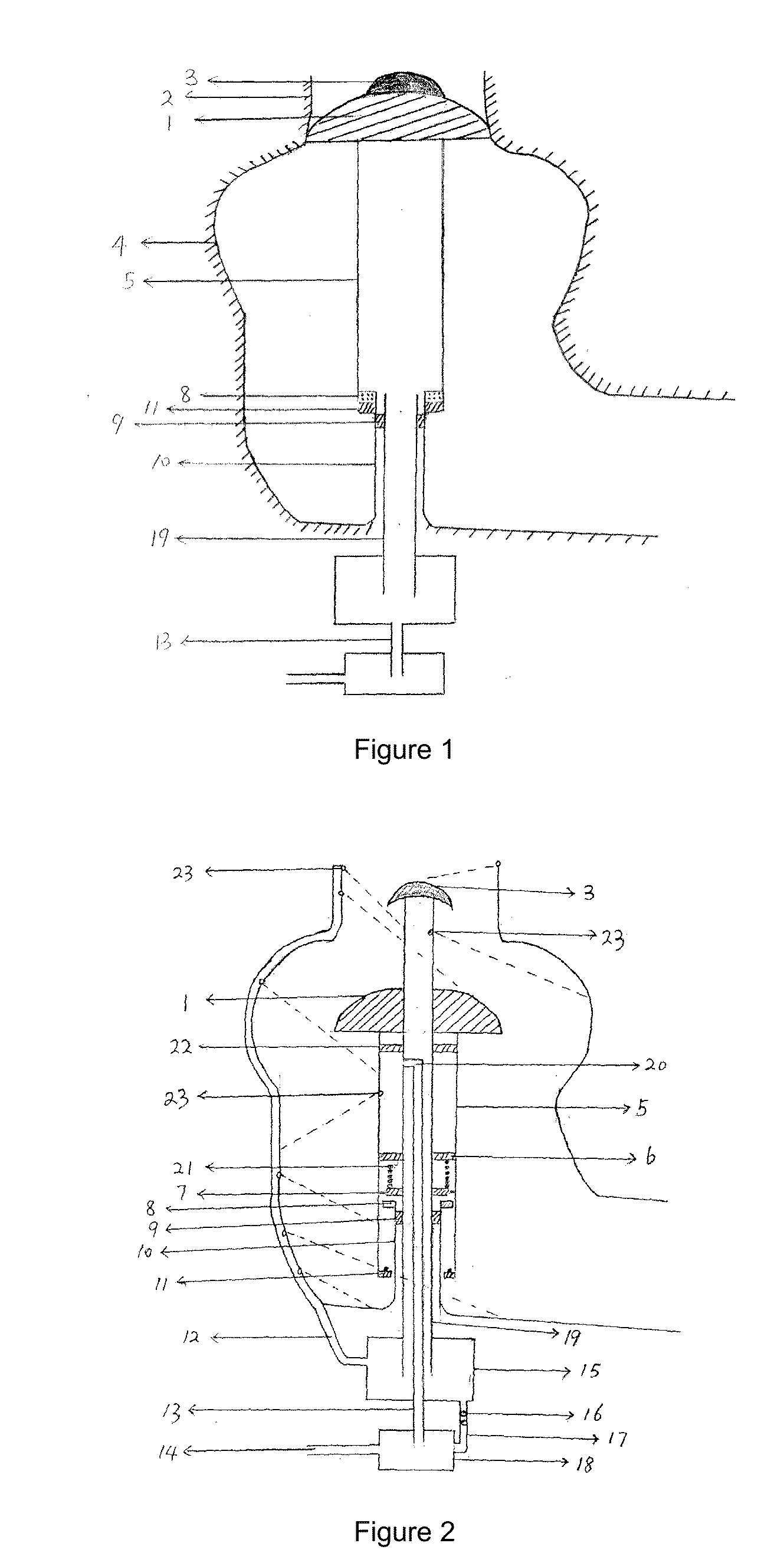

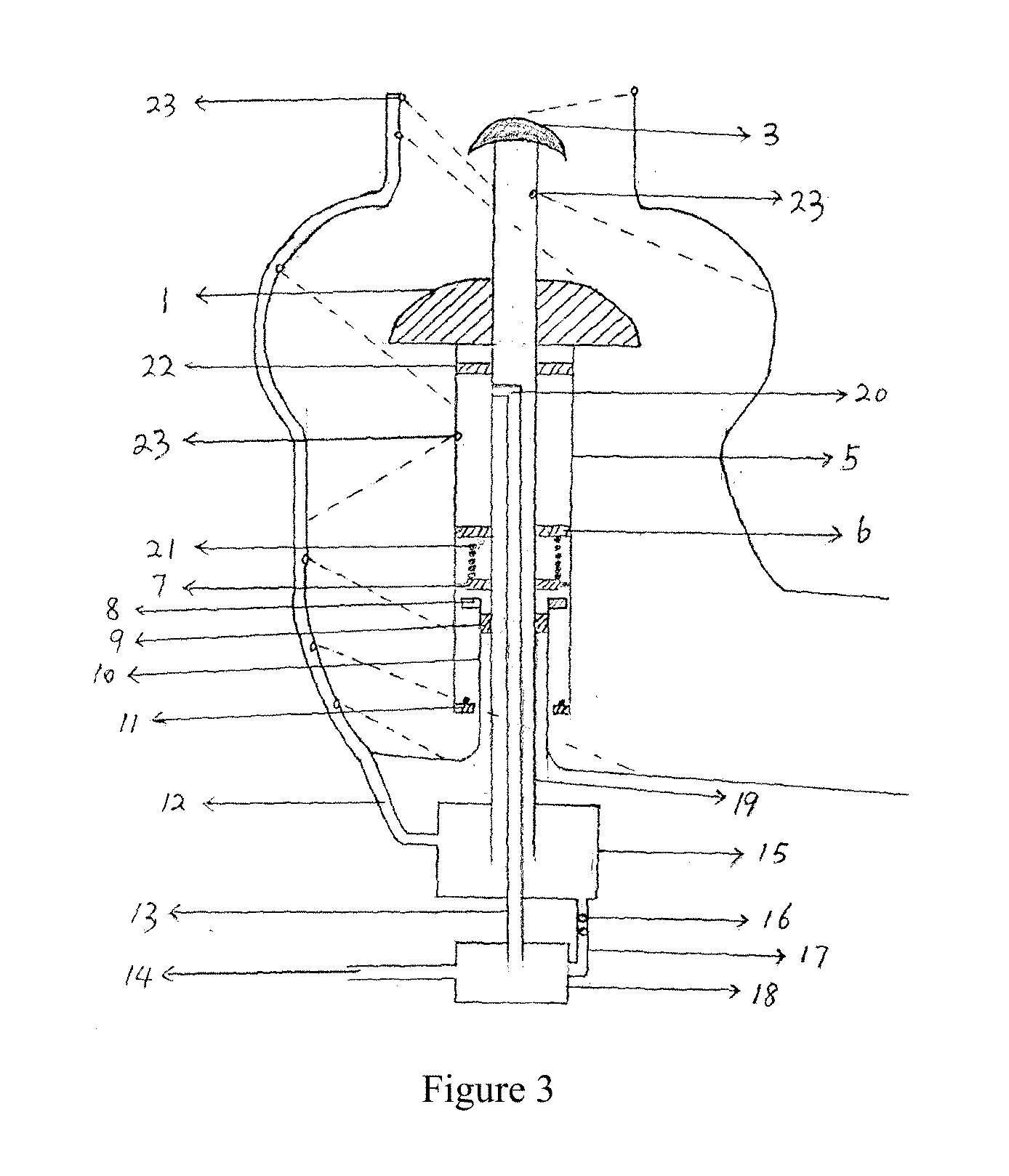

[0034]At the time of the pressure conducting plate (1) being subject to a downward force, the pressure conducting tube (3) connected to the pressure conducting plate moves downward, and its lower end penetrates a stabilizing balance plate (6). The pressure conducting tube (3) is nested with another pressure conducting tube (4) outside of it. These two tubes can move to and fro within a specified range. When the upper end of the pressure conducting tube arrives at the top of the pressure conducting tube (4), the pressure conducting tube moves downward as a result of the force exerted on it, and its end also penetrates the stabilizing balance plate (6). The pressure conducting tube (4) is nested with another fixed tube (5). When the upper end of the pressure conducting tube (4) arrives at the top of the fixed tube, the pressure conducting plate reaches its maximum downward travel distance. At this time, the spring (2) outside of the lower ends of these two pressure conducting tubes ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com