Quick connect anchor for poured concrete ceilings on metal or wood decks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

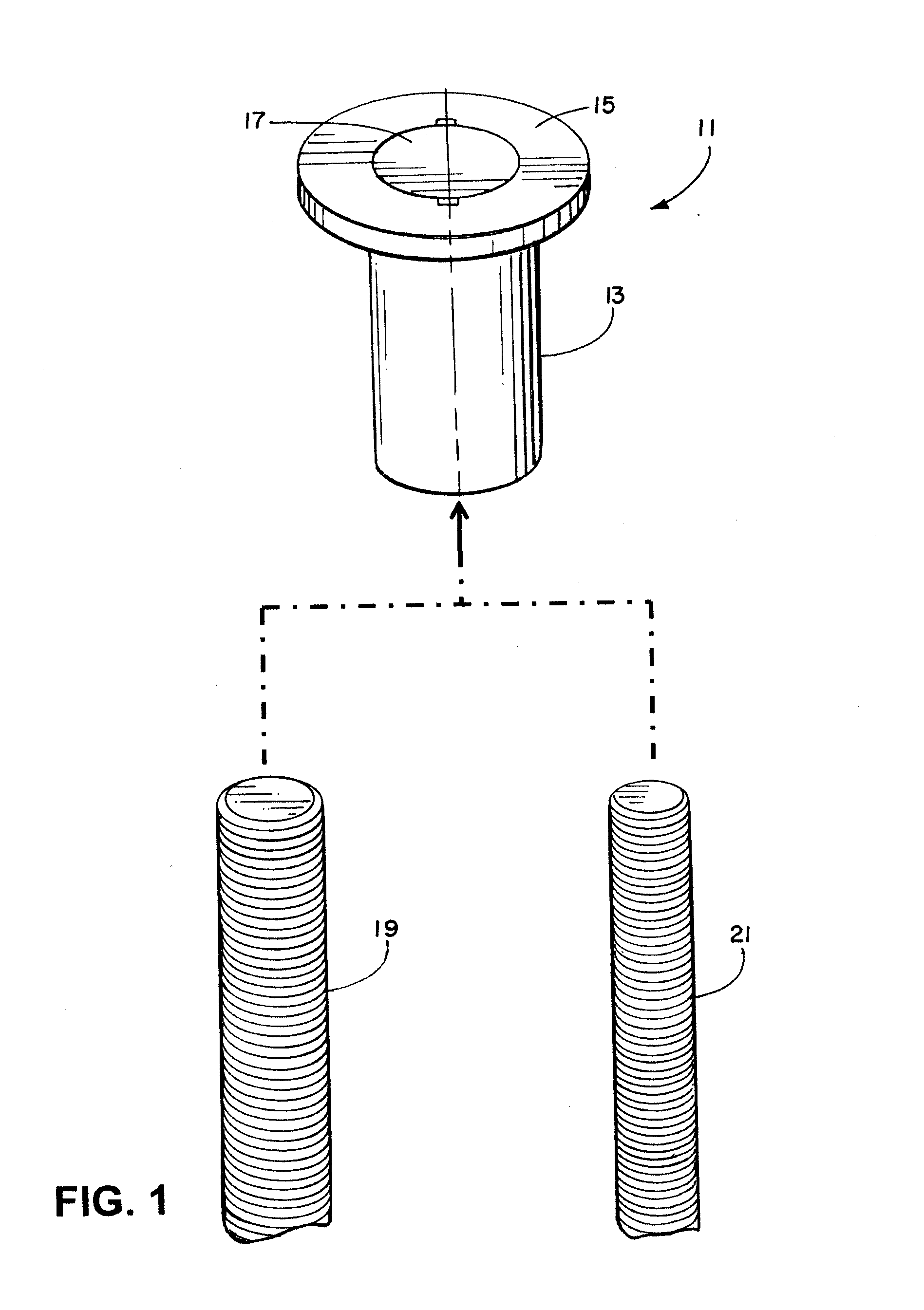

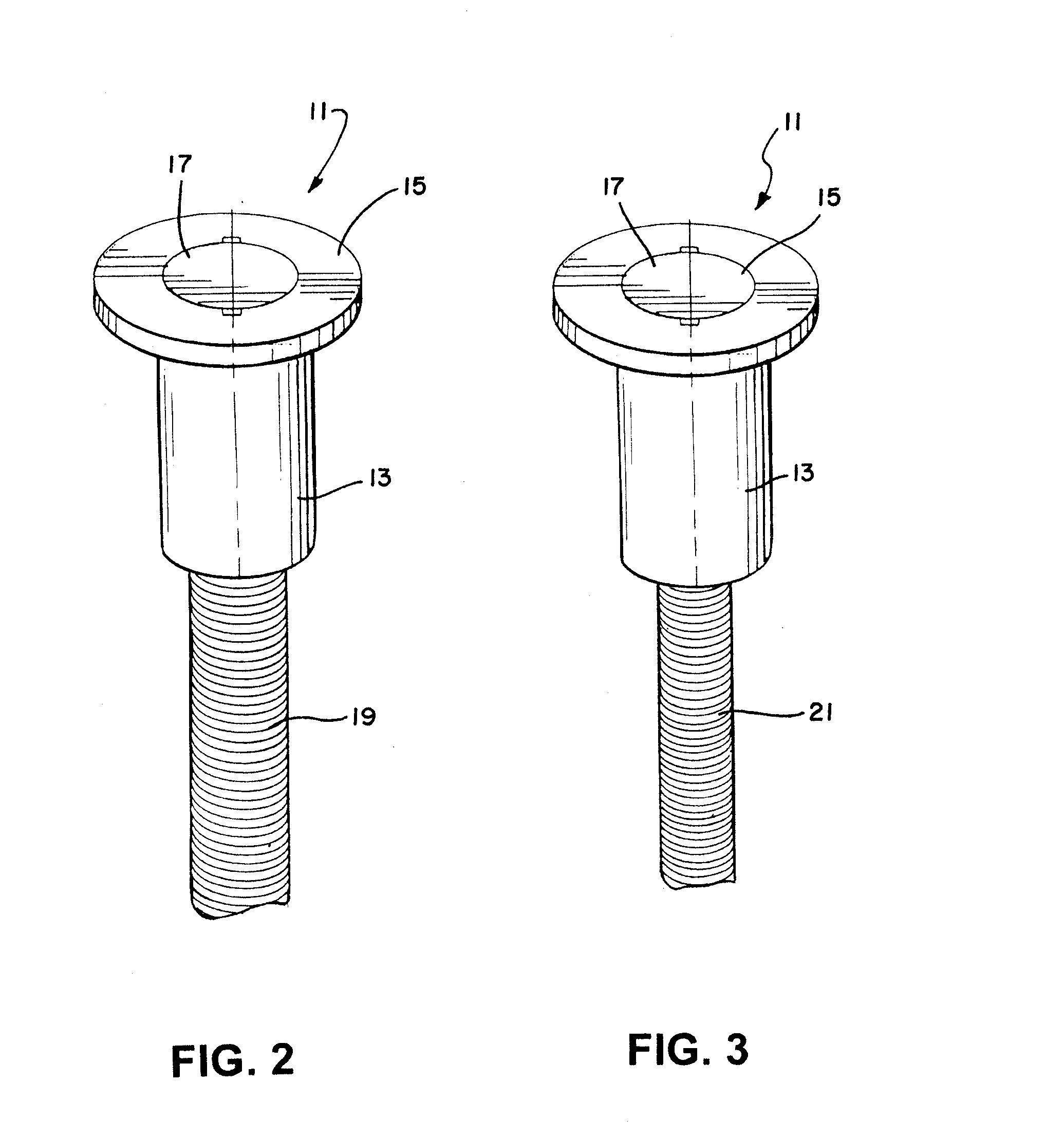

[0034]FIG. 1 illustrates a preferred embodiment of a quick connect threaded anchor 11 which has a cylindrical casing 13 made out of steel, such as stainless or galvanized steel, or a material having equivalent characteristics and strength. The cylindrical casing 13, and head section 15 are preferably formed from a single solid piece. An internal cavity of the casing 13 (FIG. 4) is capped at the head 15 by a circular plate 17. The plate 17 is preferably made of steel, such as stainless or galvanized steel, or a material having similar characteristics.

[0035]The quick connect anchor 11 is capable of receiving threaded rods 19 and 21 which have different diameters. Engagement is accomplished by a single axial thrust.

[0036]As shown in FIGS. 2 and 3, threaded rod 19 and threaded rod 21 are fully engaged by the same threaded anchor 11, even though the diameters of the rods are different. The diameter of threaded rod 19, for example, could be ½ inch. The smaller diameter threaded rod 21, fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com