Processes for the continuous regeneration of a catalyst

a technology of hydrocarbon conversion catalyst and process, which is applied in the direction of physical/chemical process catalyst, other chemical processes, separation processes, etc., can solve the problems of low activity, loss of csub>5/sub>+ yield, and metal dispersion not being allowed in the chlorination zone or drying zone, etc., to achieve effective and efficient processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

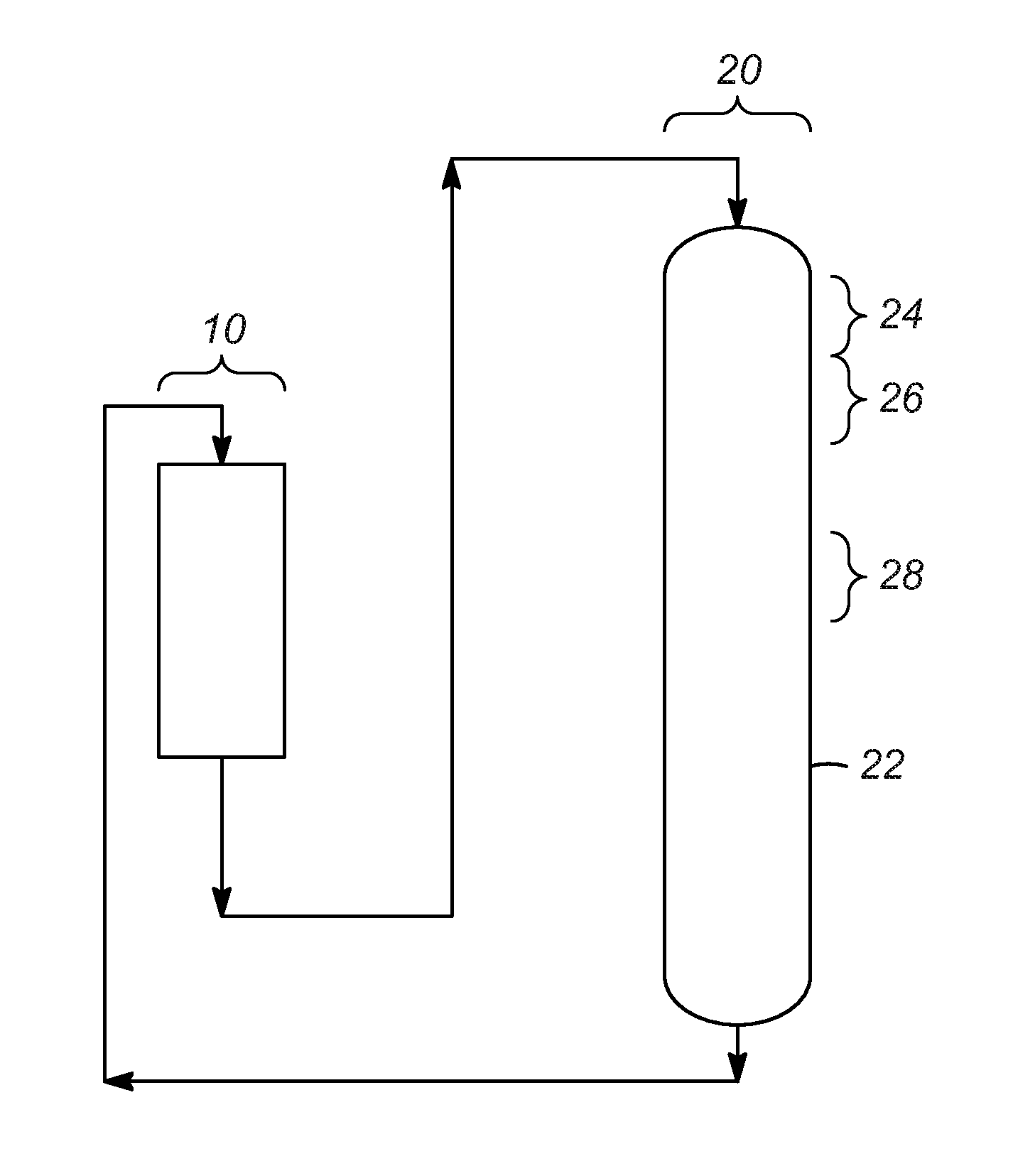

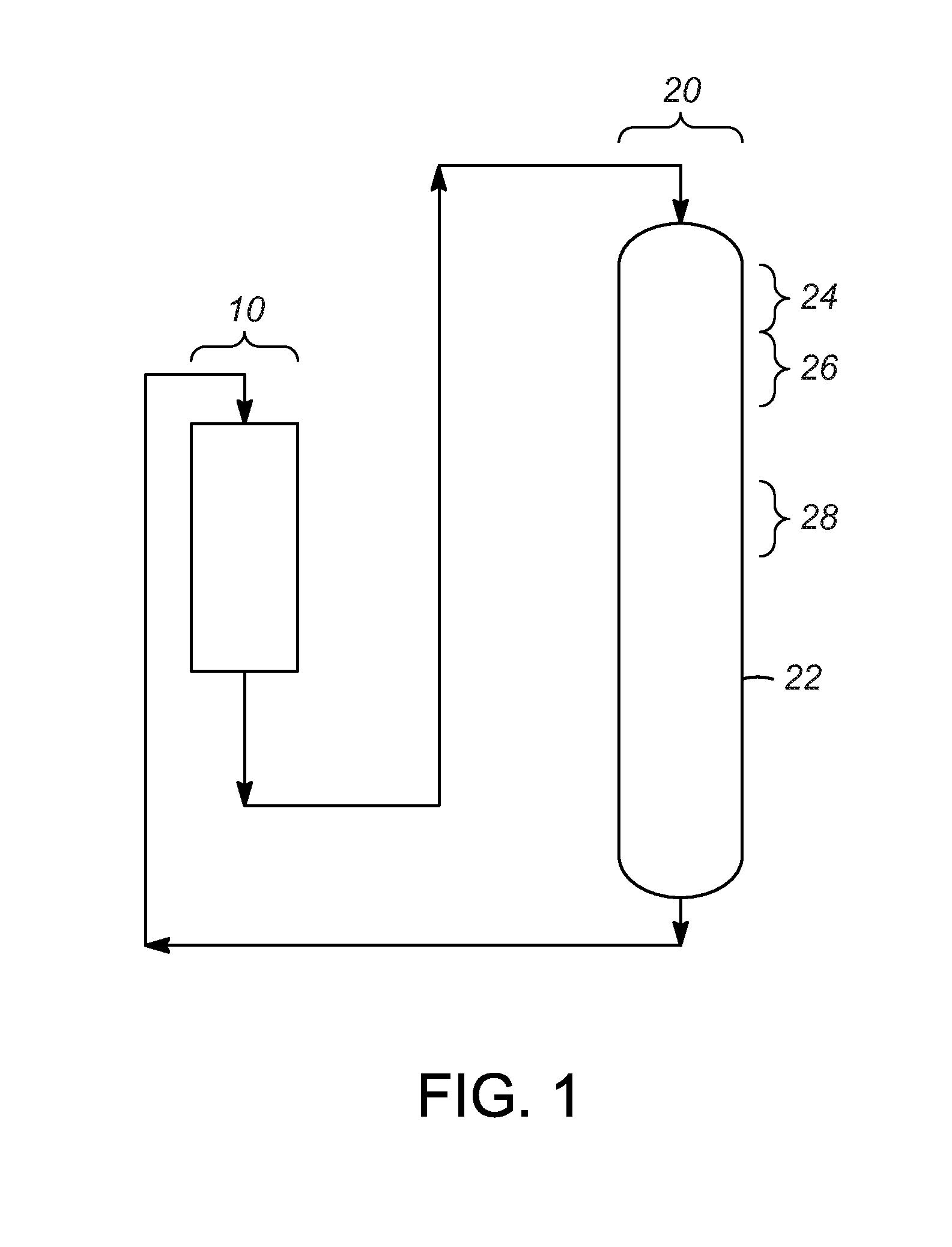

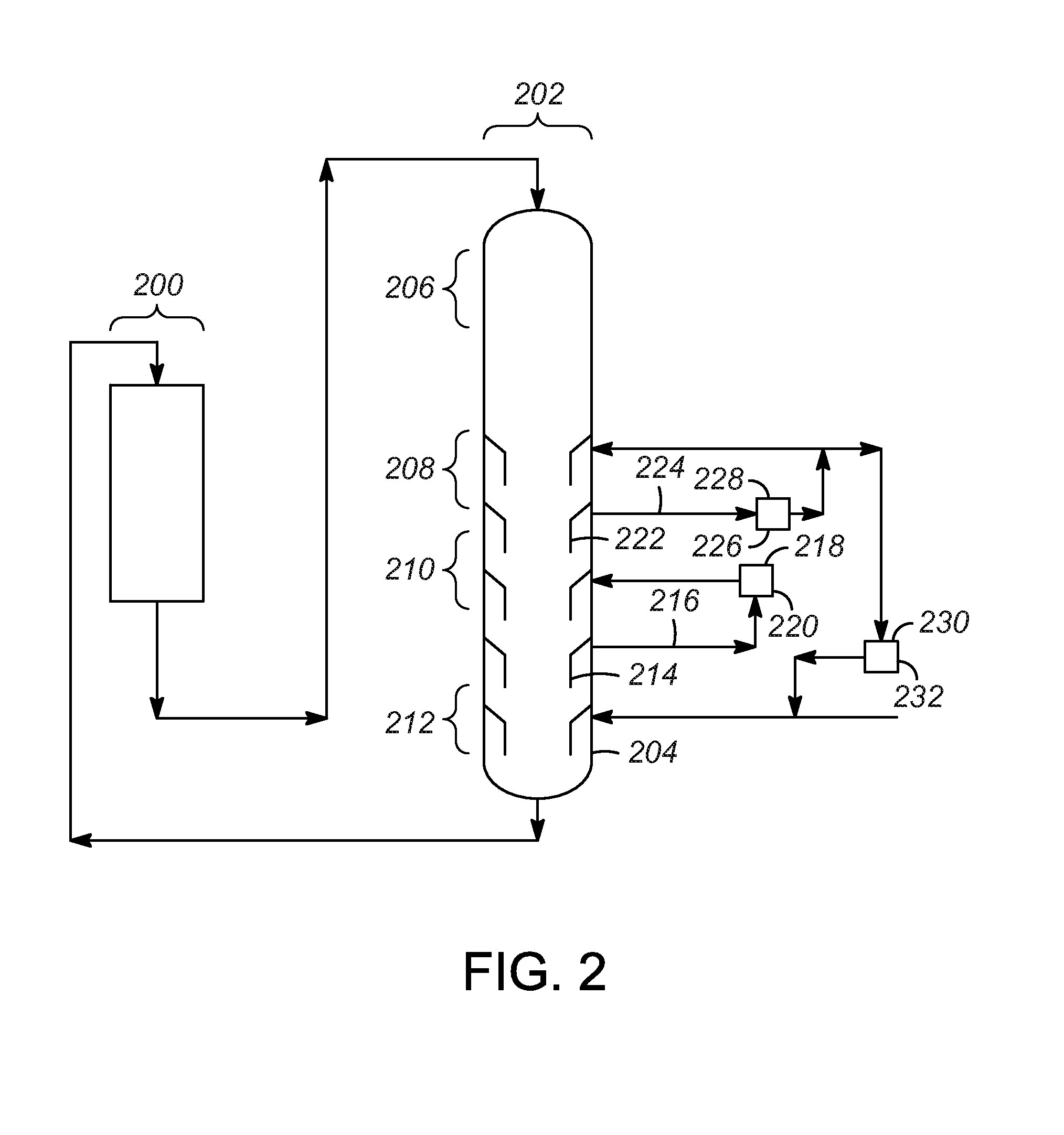

[0036]One or more processes have been developed for the regeneration of a catalyst used in a catalytic reforming reaction.

[0037]A catalytic reforming reaction is normally effected in the presence of catalyst particles comprised of one or more Group VIII noble metals (e.g., platinum, iridium, rhodium, palladium) and a halogen combined with a porous carrier, such as a refractory inorganic oxide. The halogen is normally chloride. Alumina is a commonly used carrier. The preferred alumina materials are known as the gamma, eta and theta alumina with gamma and eta alumina giving the best results. An important property related to the performance of the catalyst is the surface area of the carrier.

[0038]Catalyst particles are usually cylindrical or spheroidal, having a diameter of from about 1 / 16 th to about 1 / 8 th inch (1.5-3.1 mm), though they may be as large as 1 / 4 th inch (6.35 mm). When cylindrical, the catalyst particles have a length of from about 1 / 8 th to about 1 / 4 th inch (3.1-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com