Single Cover Passive Mattress Spinner

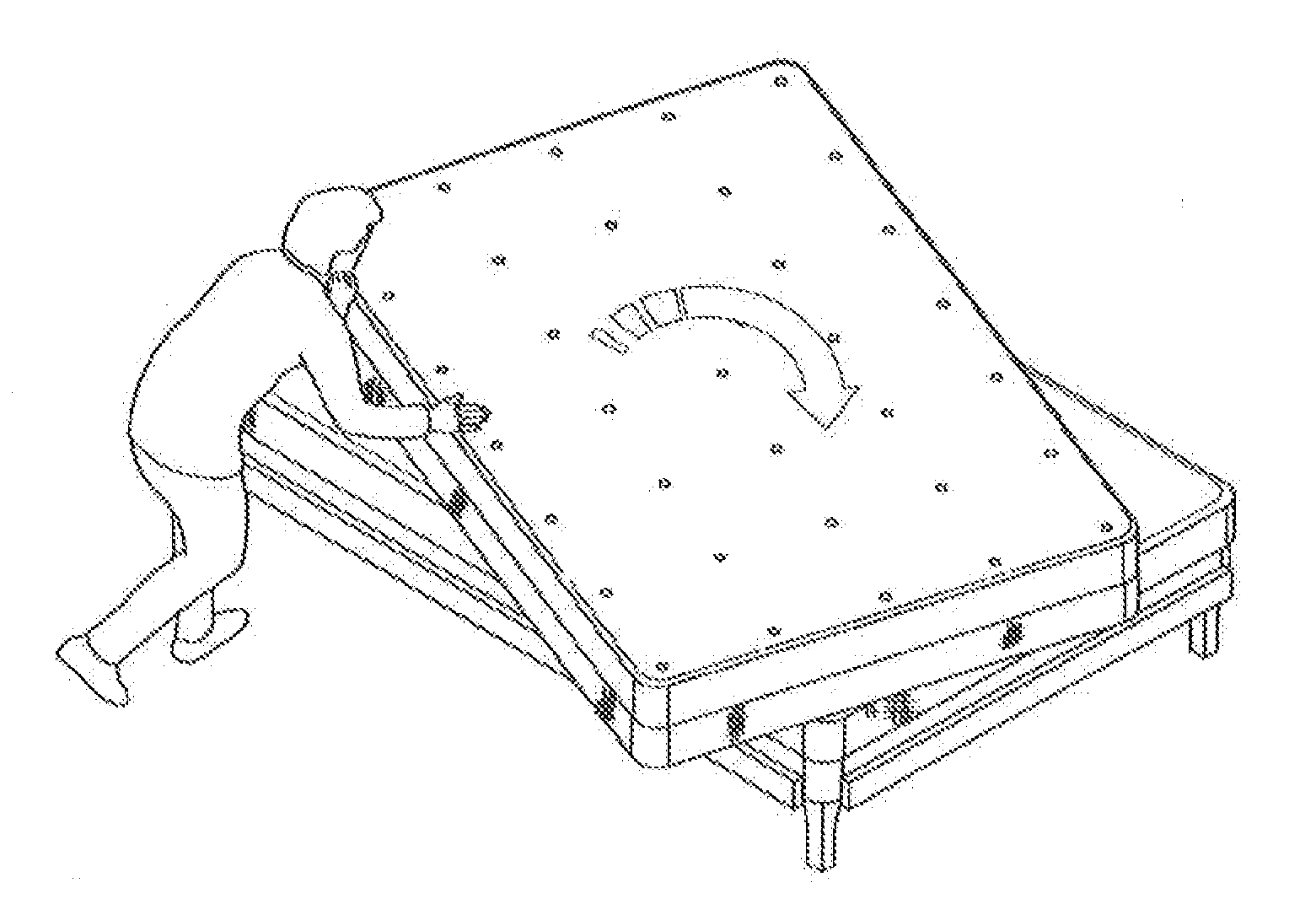

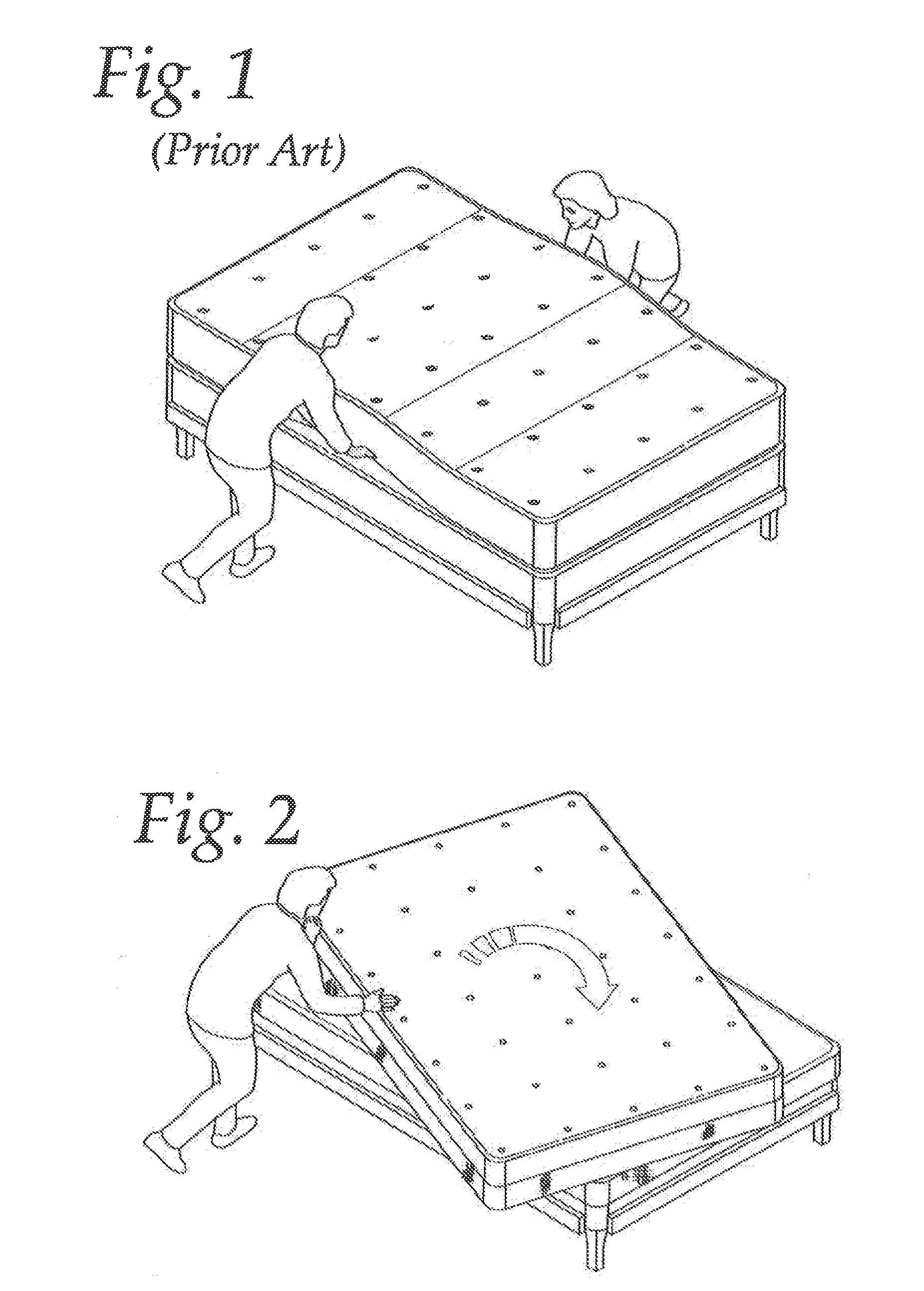

a mattress spinner and single cover technology, applied in the field of single cover passive mattress spinners, can solve the problems of difficult to rotate the mattress, the mattress is relatively heavy, and the body depression to develop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

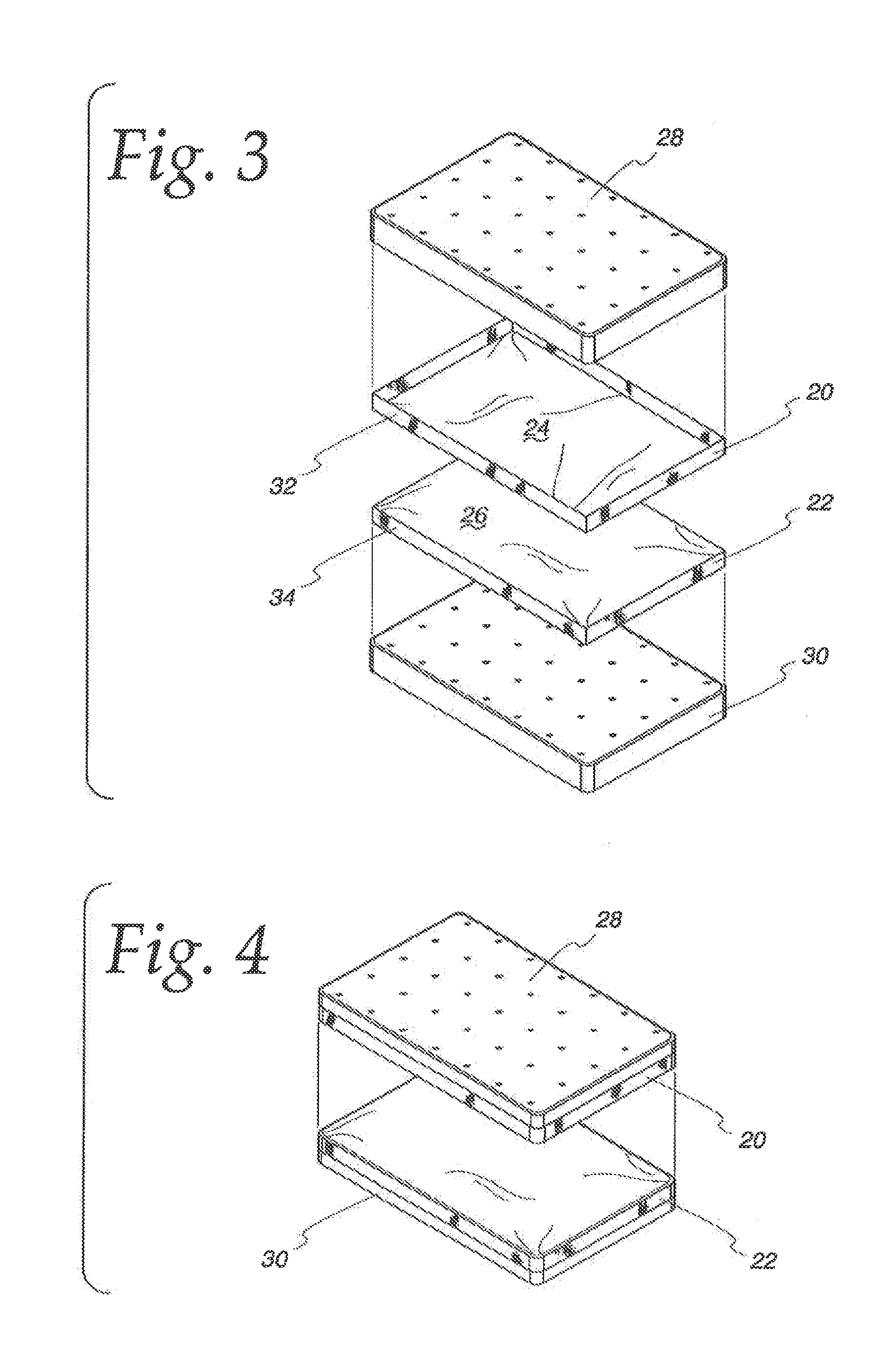

[0059]The present invention relates to mattress rotation system for facilitating rotation of a mattress in a horizontal plane with respect to a foundation. Various embodiments of the invention are described and illustrated. In all embodiments, surfaces between the mattress and the foundation are selectively placed in engagement with each other. The surfaces may be provided by two separate covers, for example, as described and illustrated in connection with FIGS. 3-11. Alternately, a single cover embodiment relies on the inherent friction or inherent surface friction of the box spring or fixed or adjustable platform. A single ply embodiment is described below and illustrated in connection with FIGS. 25, 26, 29, 30, 32, and a multiple ply embodiment is illustrated in FIGS. 34-37b. An embodiment with no covers, i.e. coverless embodiment, with embedded surfaces in both the mattress and the platform is illustrated in FIGS. 13-20. In the latter embodiment, the mattress and the foundation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| non-elastic | aaaaa | aaaaa |

| perimeter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com