Plastic closure device for tubular bags

a tubular bag and plastic closure technology, applied in the direction of flexible container closure, transportation and packaging, sacks, etc., can solve the problems of insufficient strength, bacteria will hide in the structured surface, and the structure of the anvil will damage the plastic film of the tubular bag, so as to reduce welding amplitude, the effect of cost-effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

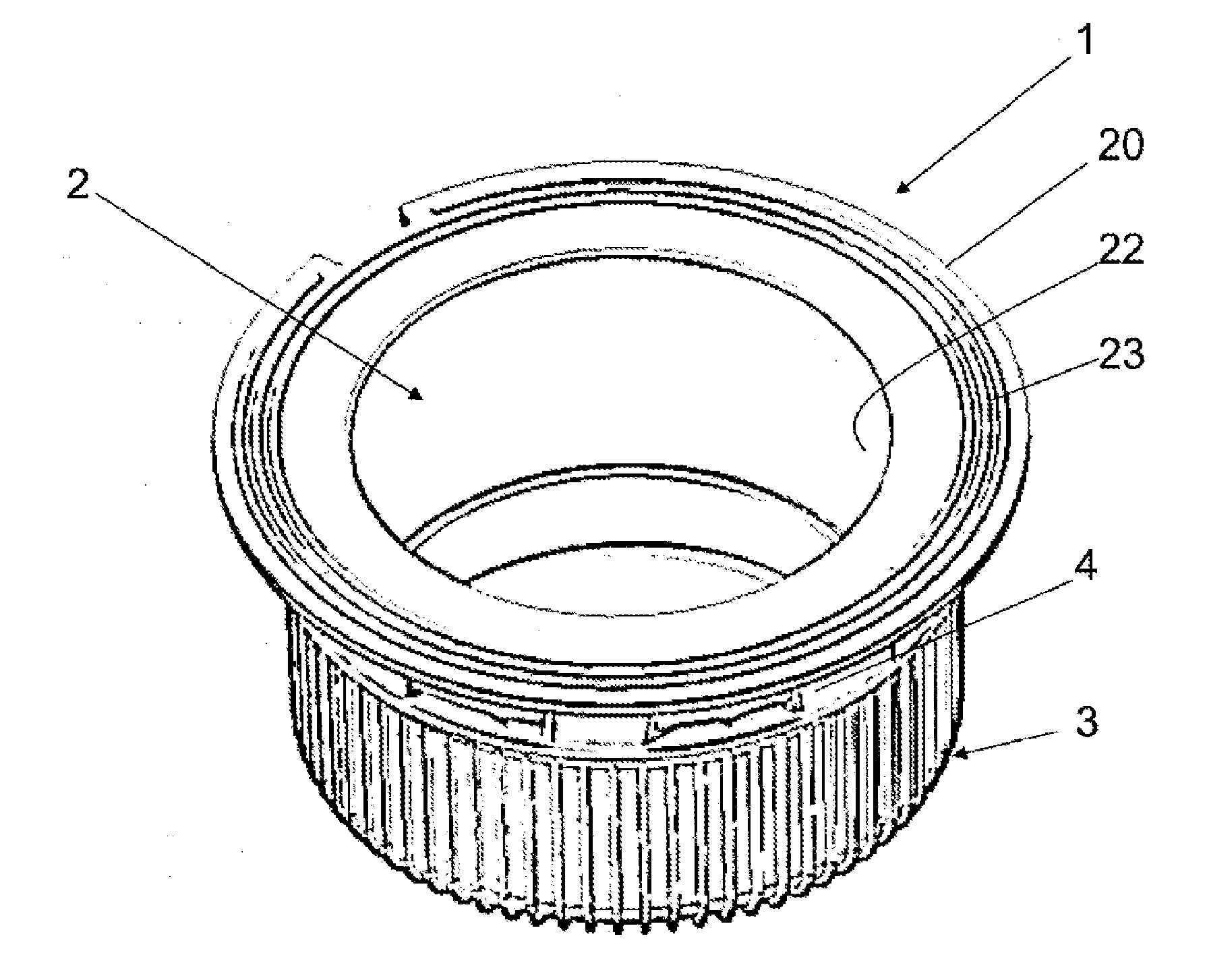

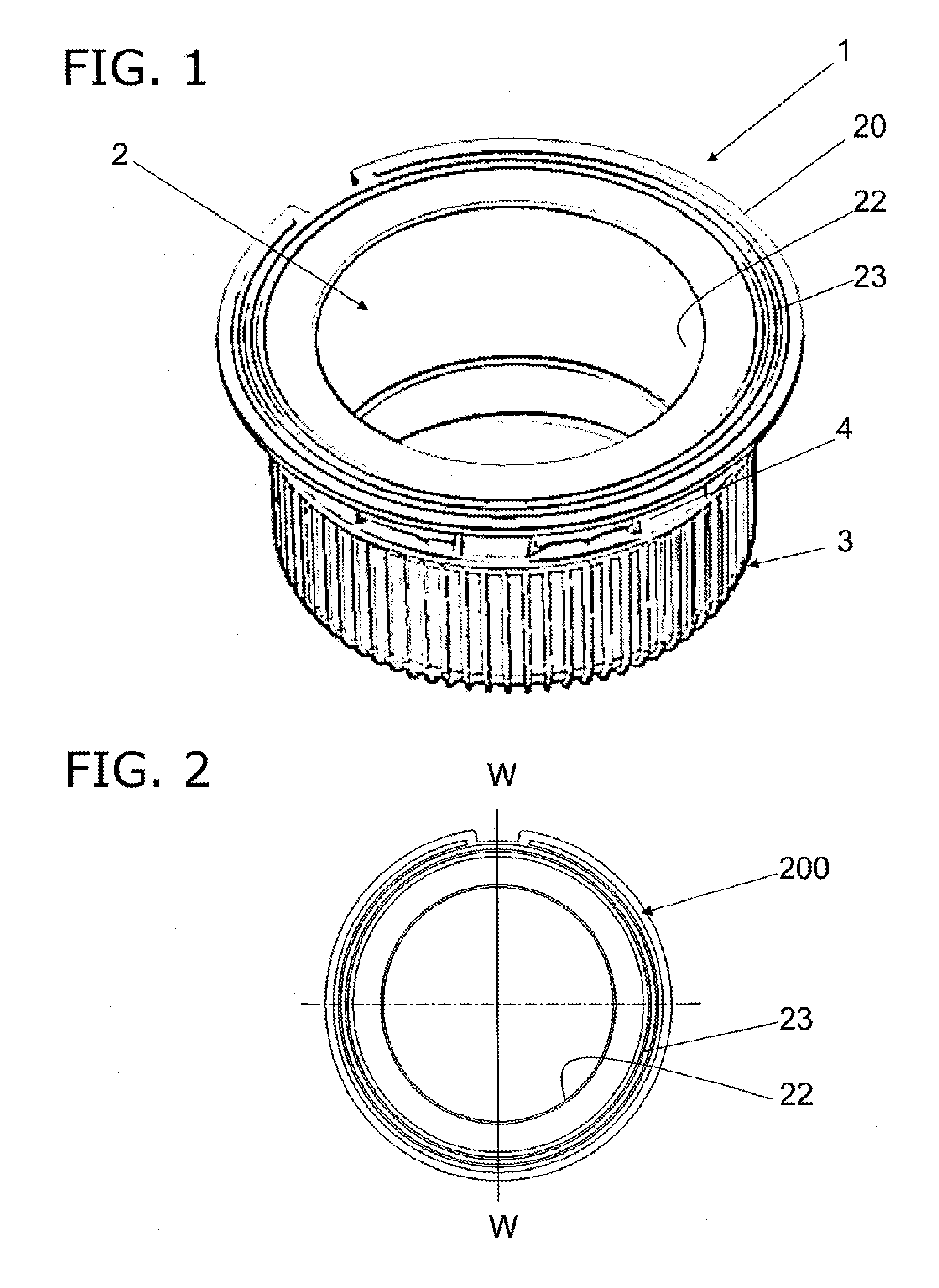

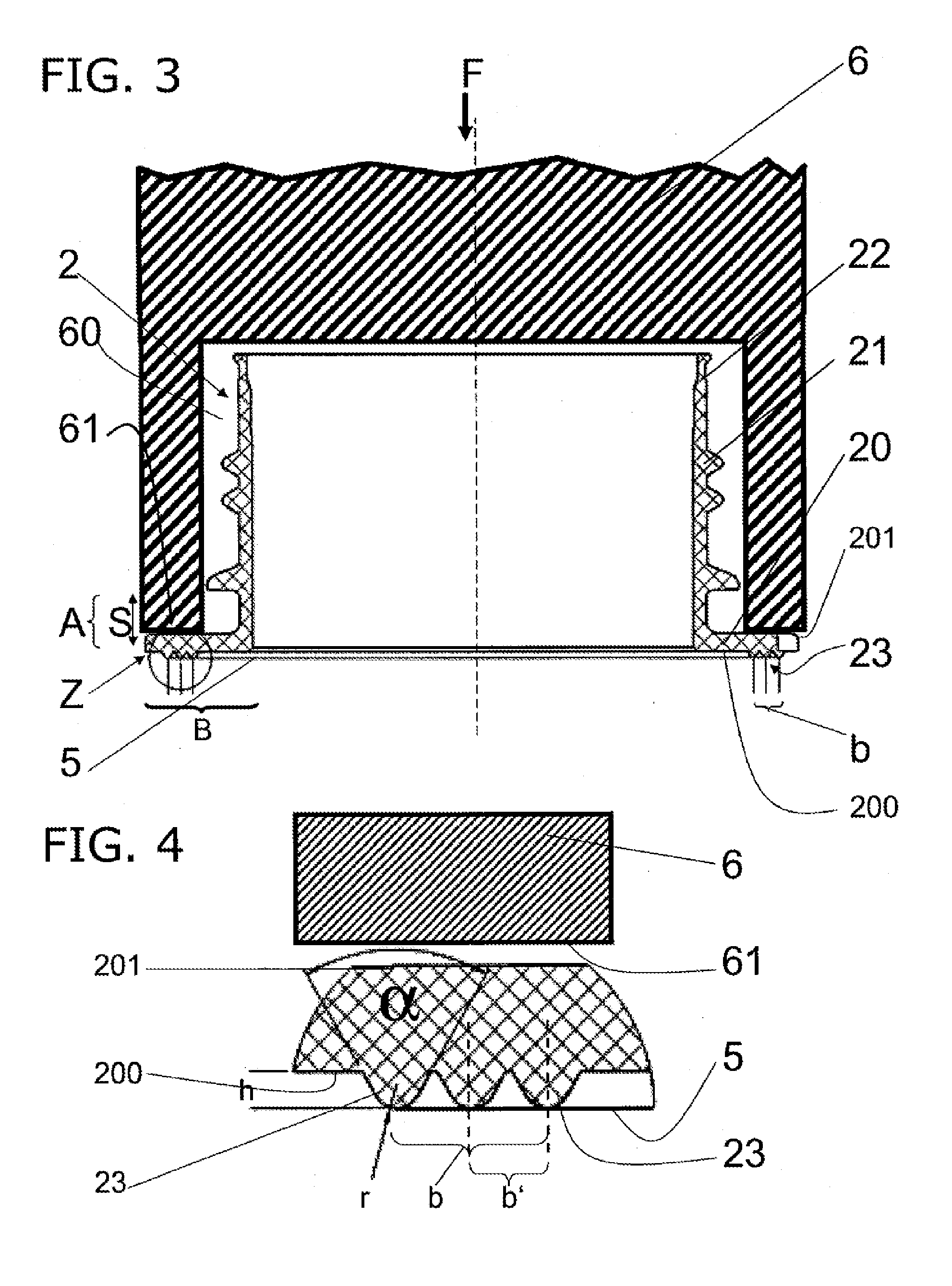

[0030]In series of tests which have compared the welding method according to the prior art, where only one energy-introducing rib is used, with the use of a plastic closure device 1 having a plurality of energy-introducing ribs, a significant reduction in the necessary static joining force F, and, above all, in the maximally necessary power, was able to be measured. Here good results were manifested with the use of energy-introducing arrangements comprising two and three energy-introducing ribs 23, wherein the best results were able to be achieved with three energy-introducing ribs 23.

[0031]The weld fastening of a bottom part of a plastic closure device according to the prior art is compared with a bottom part 2 with special energy-introducing arrangement comprising three energy-introducing ribs 23 on identical plastic films 5 each having a thickness of 5 mil, which corresponds to a thickness of (1 mil=25.4 μm) about 125 μm. The surface areas of the flange bottom sides 200 and flang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| distance apart | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com