X-ray shield grating and x-ray talbot interferometer including x-ray shield grating

a technology of x-ray shield and talbot, which is applied in the direction of material analysis using wave/particle radiation, instruments, and handling using diaphragms/collimeters, etc., can solve the problems of insufficient x-ray transmission contrast and the decrease of the amount of x rays which reach the detector

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

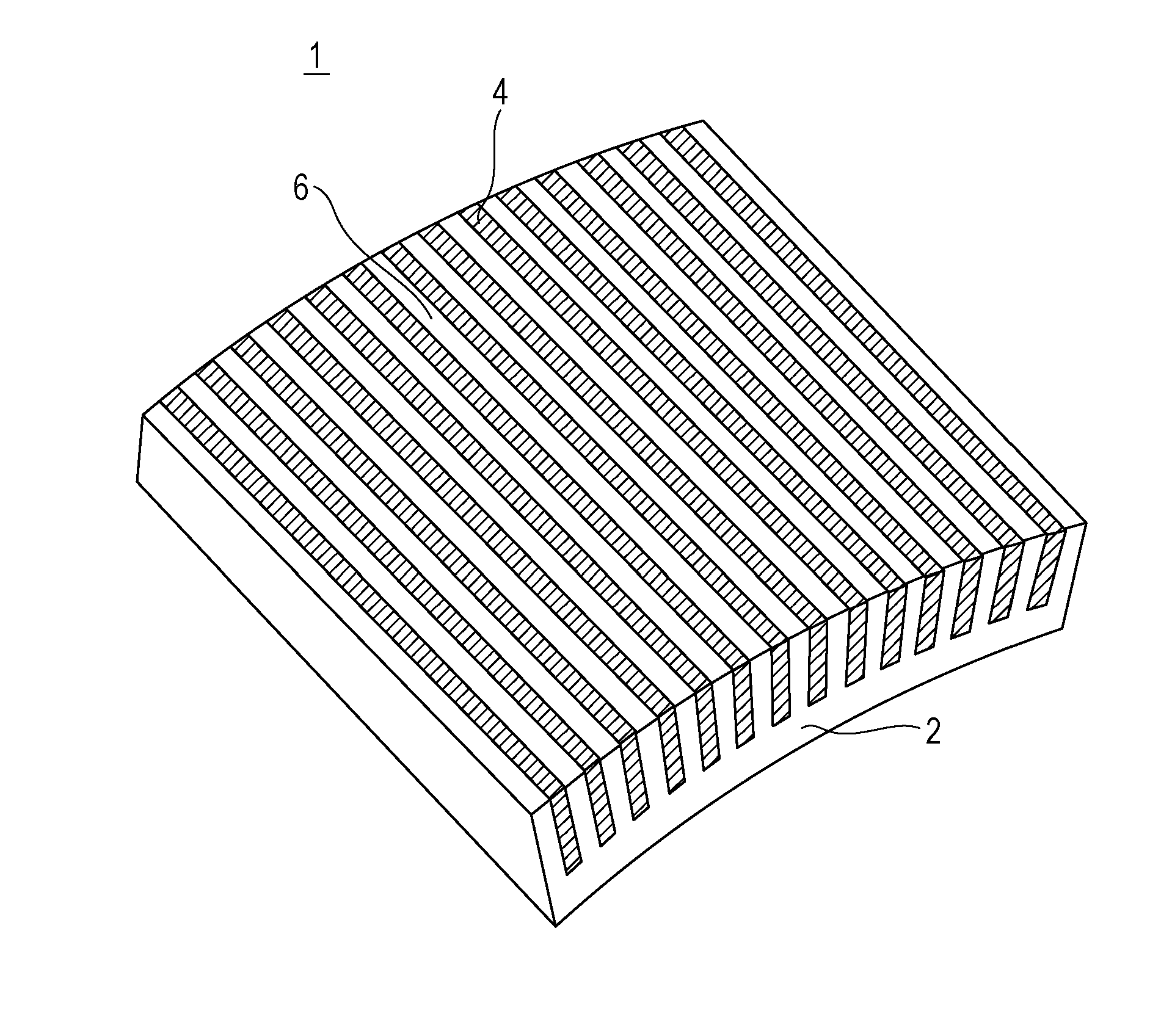

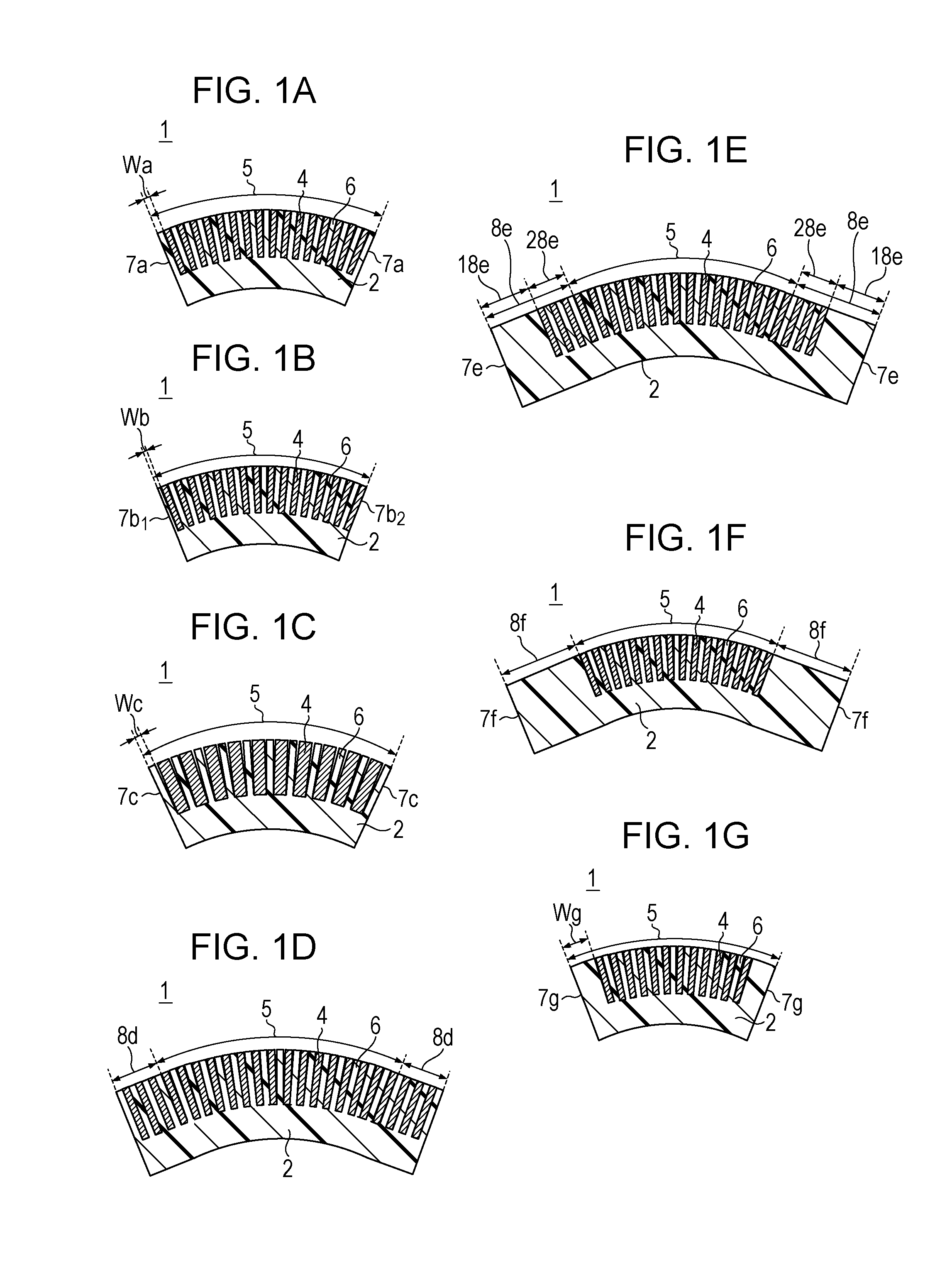

example 1

[0064]In Example 1, a more specific example of the X-ray shield grating 1 illustrated in FIG. 1A will be explained. In Example 1, a silicon substrate is used as a substrate, and gold is used as metal. A method for producing the X-ray shield grating 1 according to Example 1 will be explained with reference to FIGS. 4A to 4E and FIGS. 5A and 5B.

[0065]First, a substrate on which a plurality of recessed portions are arranged and metal is arranged in each of the recessed portions is prepared. Such a substrate may be obtained by performing steps, for example, illustrated in FIGS. 4A to 4D. The steps illustrated in FIGS. 4A to 4D will be explained below.

[0066]A silicon substrate with a diameter of 100 millimeters, a thickness of 200 micrometers, and a resistivity of 0.02 Ωcm is used as the substrate 2. By thermally oxidizing the silicon substrate at 1,050 degrees Centigrade for 75 minutes, thermal oxide films 20 of about 0.5 micrometers are formed on front and rear surfaces of the silicon ...

example 2

[0077]In Example 2, a specific example in which a substrate thicker than that used in Example 1 is used and an X-ray shield grating is bent in a method different from Example 1 will be explained. However, the other points are same as those in Example 1, and therefore a detailed explanation for those same points will be omitted.

[0078]Processing up to the step of cutting off end portions is performed in a manner similar to Example 1 with the exception that a silicon substrate with a thickness of 300 micrometers is used as the substrate 2, and the substrate 2 of 55 millimeters x 25 millimeters on which a plurality of recessed portions are arranged and gold is arranged in each of the recessed portions is obtained.

[0079]In Example 2, a step of bending the substrate whose end portions have been cut off, in the direction in which the plurality of recessed portions are arranged, is performed using supporting members 19 illustrated in FIGS. 6A and 6B. The supporting members 19 used in Exampl...

example 3

[0082]In Example 3, a specific example of the X-ray shield grating 1 illustrated in FIG. 1F will be explained. Example 3 is different from Example 1 in that the end portions of the substrate are cut off in such a manner that the width of the substrate in the end portions of the substrate is 10 millimeters in the step of cutting off the end portions of the substrate and that the substrate is bent in such a manner that not the entire substrate but only part of the substrate serves as a bent region. The other points are the same as those in Example 1, and a detailed explanation for those same points will be omitted.

[0083]In Example 3, a step of cutting off end portions of the substrate 2 is performed. In Example 3, end portions of the substrate are cut off in such a manner that the shortest distance from an end face of the substrate to metal is 10 millimeters, and the substrate 2 of 75 millimeters x 25 millimeters is thus obtained.

[0084]As illustrated in FIG. 7, by using the supporting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com