Fiber composite component with an electrically conductive fiber material for reinforcement as well as a device for its manufacture

a fiber composite and electrically conductive technology, applied in the direction of ornamental textile articles, transportation and packaging, layered products, etc., can solve the problems of unfavorable lightning protection, unfavorable lightning protection, and limited load-bearing capacity of structural components made out of this reinforcement. to achieve the effect of reliable lightning protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

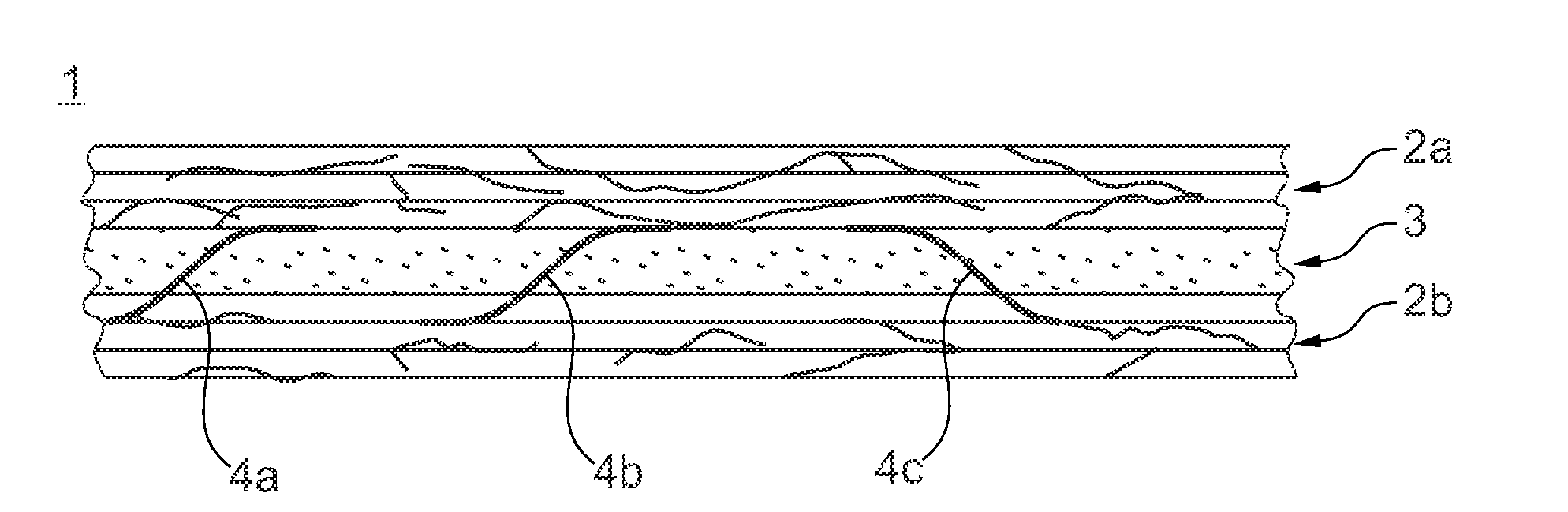

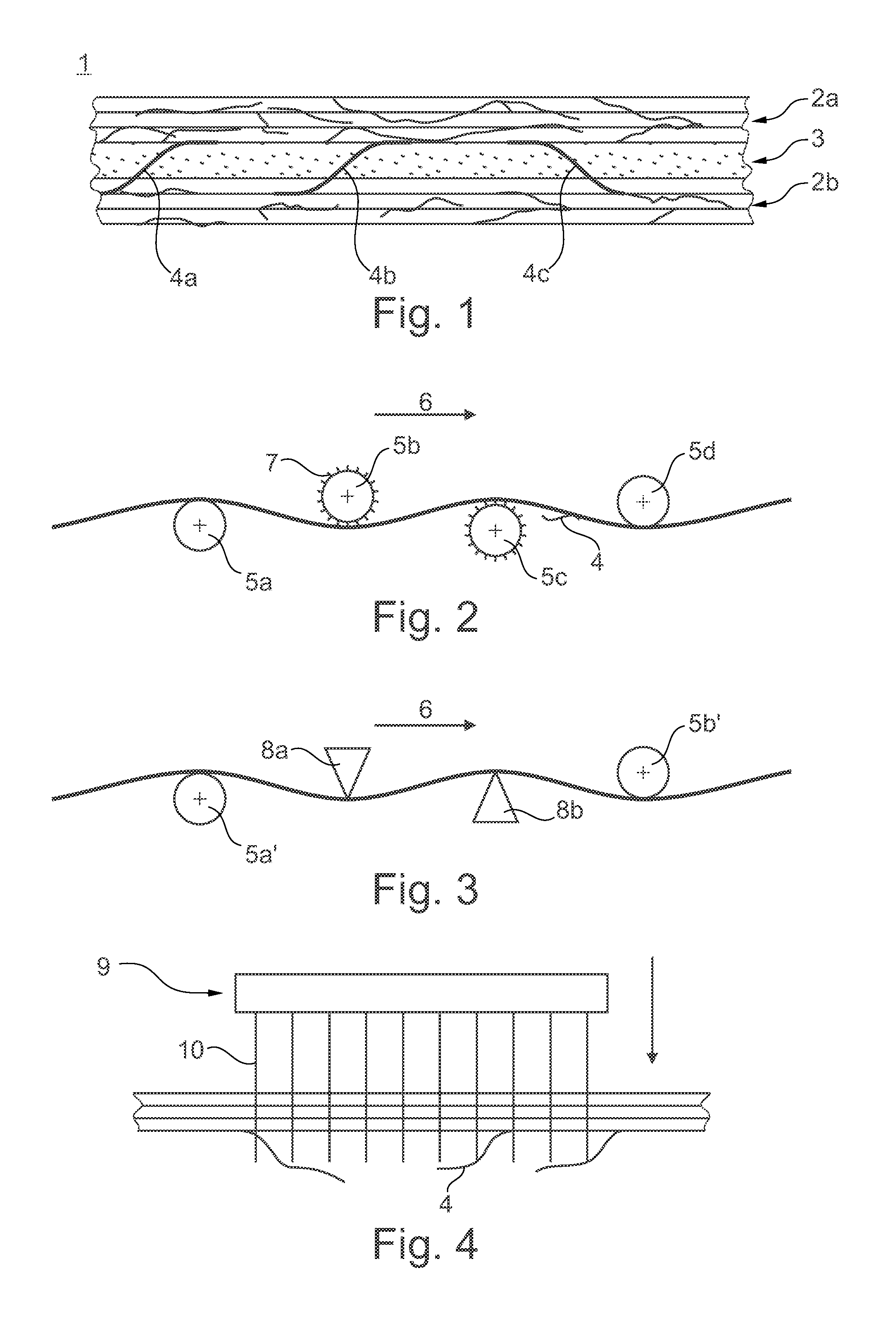

[0025]According to FIG. 1, a fiber composite component 1 depicted here in a cross sectional cutout as a structural component of an aircraft consists of two layers 2a and 2b made out of a mat-shaped fiber material, here a nonwoven material comprised of carbon fibers, which is embedded into a synthetic resin matrix. Situated between the two layers 2a and 2b of the fiber material is a synthetic resin layer 3. In order to establish an electrical bridge connection in the thickness direction of the fiber composite component 1, individual fibers protrude as free fiber ends 4a to 4c from the flat plane of the layers 2a, 2b of the mat-shaped fiber material, and come to abut against the surface of the opposing layer 2b or 2a.

[0026]In order to fabricate such a mat-shaped fiber material with superficially protruding free fiber ends, use can be made of a device according to FIG. 2, which transports the fiber material (bolded line) along a processing section 6 by means of several rollers 5a to 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electrical conductivity | aaaaa | aaaaa |

| Structure | aaaaa | aaaaa |

| Speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com