A box for carrying the liquid crystal display panel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

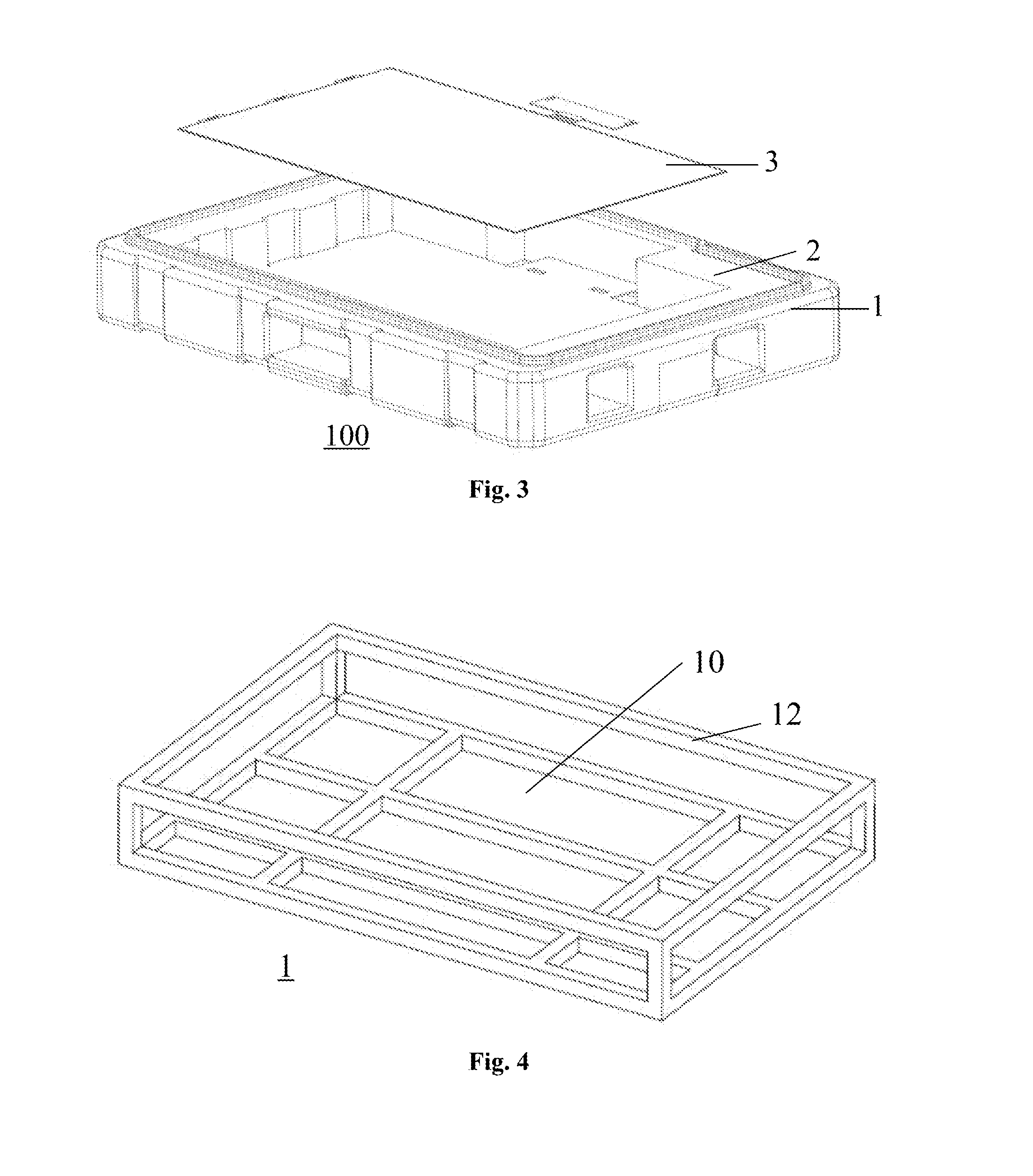

[0027]The base 1 can be selected different structures. Refer to FIGS. 4-6, in the present invention, the base 1 is a frame structure which is made of stainless material. The stainless supplying edges 12 are vertically intersected. The transverse supplying edges are in parallel, and the endwise supplying edges are also in parallel. The hollow holes 10 are formed by the intersected with the transverse supplying edges and the endwise supplying edges. The hollow holes 10 are symmetrically opening at the bottom arm and / or the side arm of the base 1. The areas of the hollow holes 10 are to be the same to balance the base 1. The weight of the whole base 1 can be lightened with the hollow holes 10. Refer to FIGS. 6-7, when the inner shell 2 is located in the base 1, the outer wall of the inner shell 2 is matched with the inner wall of the base 1 to load the liquid crystal display panel. The frame type base is made of metal with a lot of hollow holes, so the material of the base can be saved...

second embodiment

[0028]Refer to FIGS. 7-9, in the present invention, the base 1 is formed by foam molding. The hollow holes 10 are opening at the bottom arm and / or the side arm of the base 1. The side arm and the bottom arm of the base are hollow body. The hollow hole 10 is to be cuboid shaped, the relation of each side of the hollow hole is 2×L×W>2×L×H+2×W×H, Refer to FIGS. 8b-9b, L is the length of the hollow hole, W is the width of the hollow hole, H is the depth of the hollow hole. After blowing into the hollow holes 10, the hollow holes 10 can be filled into the same material. The filled area is S1=2×L×W+2×W×H, and the hollowing area of the hollow hole 10 is S2=2×L×H, and the filled area S1 is larger than the hollowing area S2, that is, S2>S1. After the hollowing out process, about 2×L×H of the stainless material can be saved. But each side arm and bottom arm of the base 1 should be remain sealed off. Therefore, if the moderate same material is embedded into the hollow holes 10, the filled area...

third embodiment

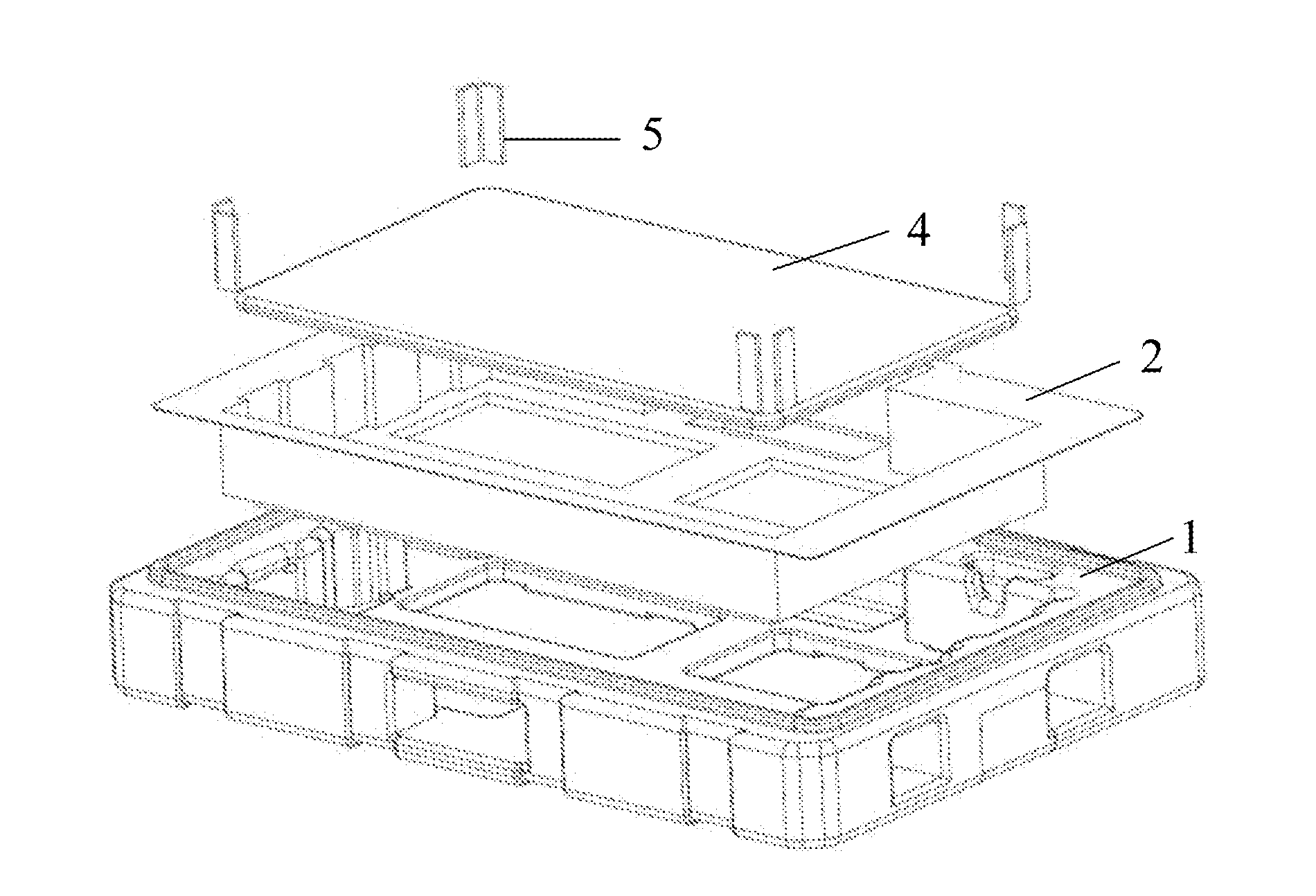

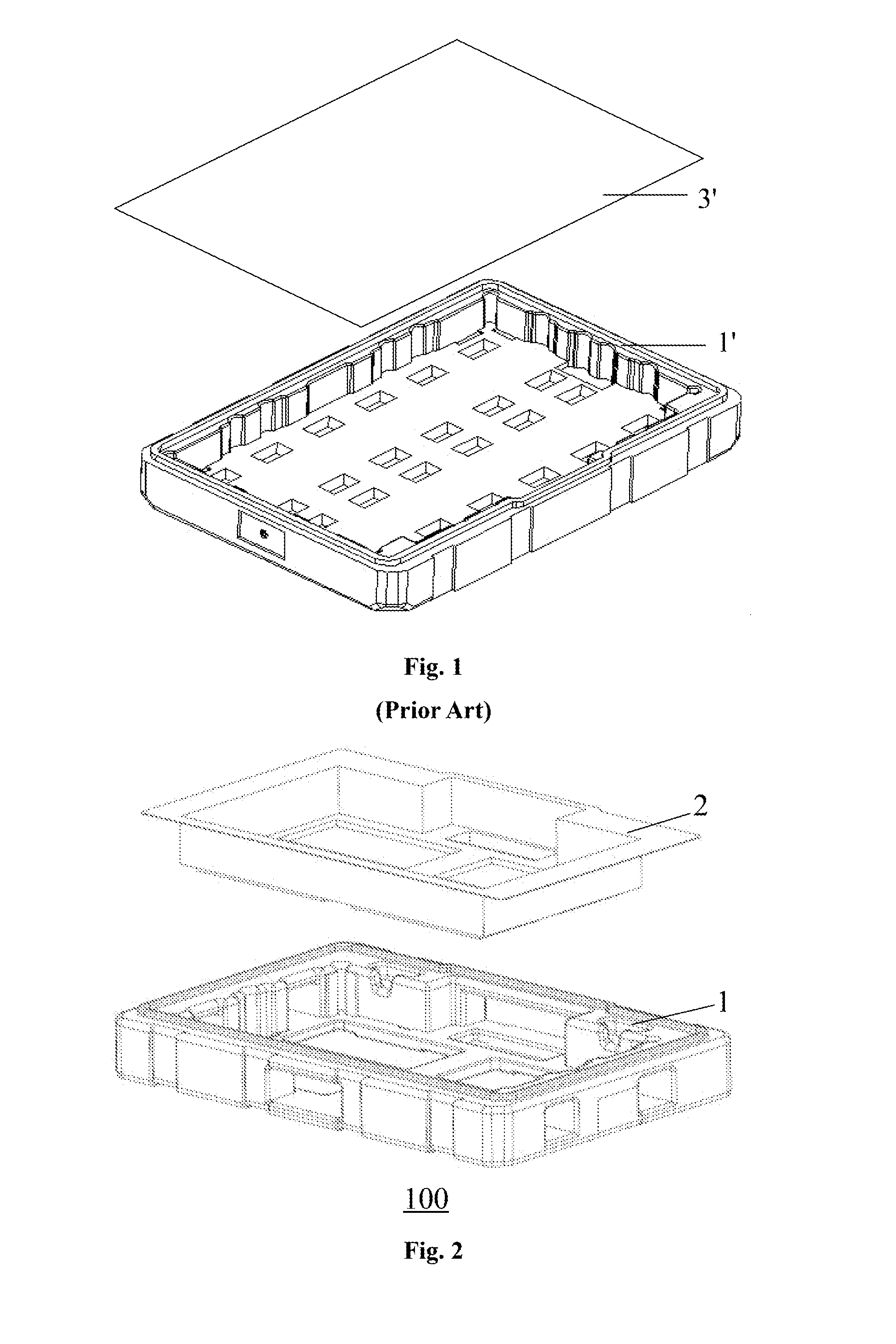

[0030]Refer to FIGS. 10-11, for enhancing the buffer performance of the whole box 100, the box 100 is also addition provided for a buffer gasket 4. Refer to FIG. 10, in the present invention, the buffer gasket 4 is placed between the base 1 and the inner shell 2. Refer to FIG. 11, in the forth embodiment, the buffer gasket 4 is placed between the inner shell 2 and the liquid crystal display panel 3 for relieving the concussion of the liquid crystal display panel on the placing or transporting process. When the buffer gasket 4 is placed between the base 1 and the inner shell 2 by adjoining, the area of the buffer gasket 4 is equal to the area of the bottom area of the inner shell 2. Therefore, the shaking of the liquid crystal display panel on the inner shell 2 can be multilevel buffered with the inner shell 2 and the buffer gasket 4. That is to say, the buffer gasket 4 can be placed in the inner shell 2, and there is not adjoining layer between the buffer gasket 4 and the inner shel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com