Electronic cigarette

a technology of electronic cigarettes and cigarette shells, applied in tobacco, mechanical equipment, container discharge methods, etc., can solve the problem of prone to clogging of ventilation holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment one

[0039]As shown in FIGS. 5-8, a clamping element 6 is sleeved on an end portion of the extension part 31. The second lead wire 52 is clamped between the extension part 31 and the clamping element 6, and is further electrically connected to the second electrode 3.

[0040]A blind hole is axially defined on the end portion of the extension part 31. The clamping element 6 is an element having an “E”-shaped axial section matching with the blind hole. Or, the first air channel 35 runs through two ends of the second electrode 3, and a second through-hole communicated with the first air channel 35 runs through the clamping element 6 along an axial direction of the clamping element. The clamping element 6 is an element having an “E”-shaped axial section, and the second through-hole axially runs through the middle of the “E”-shaped element (as shown in FIG. 8 specifically).

[0041]At this time, the first lead wire 51 is clamped between the insulating ring 34 and the first electrode 2. The clamping...

embodiment two

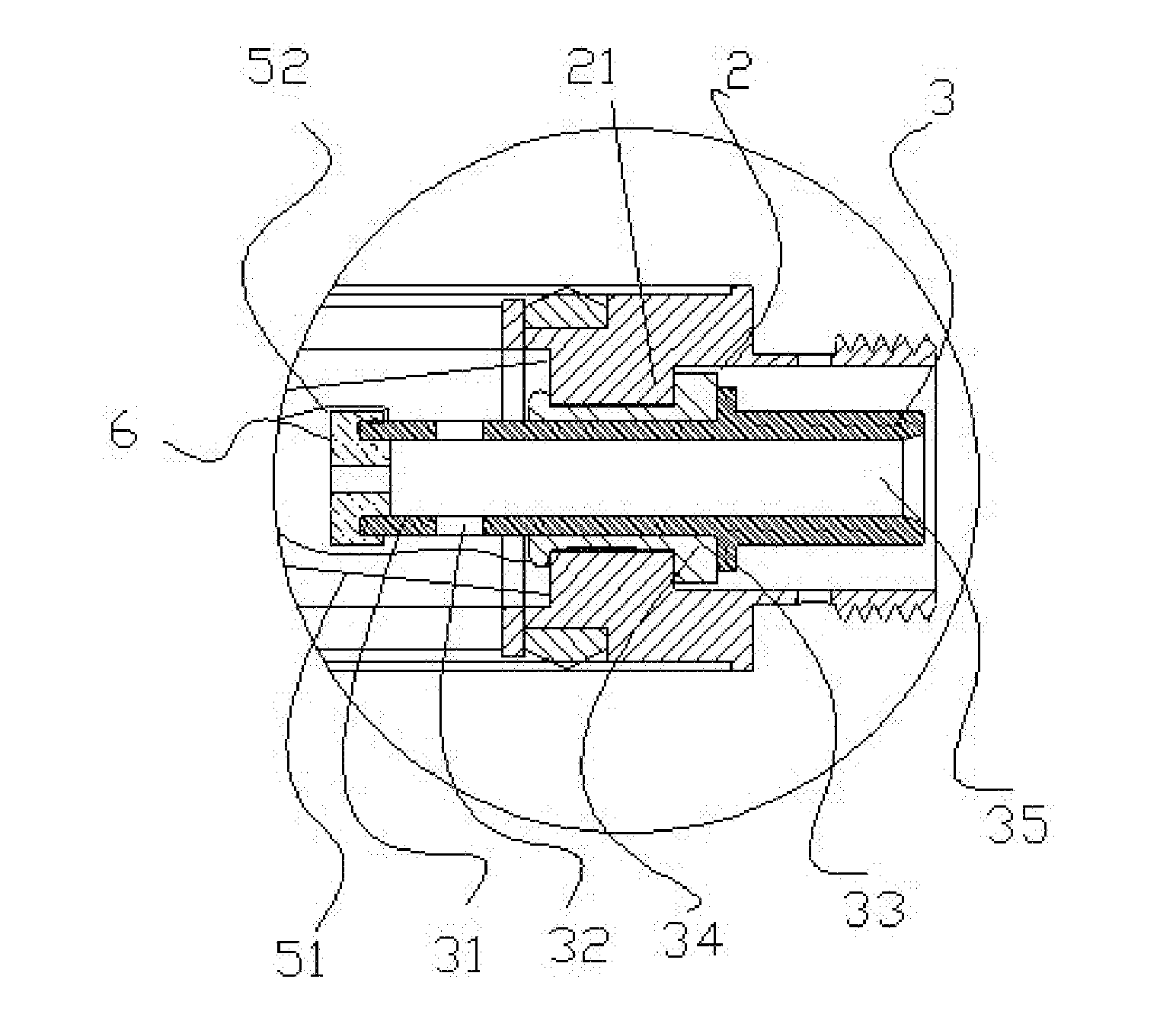

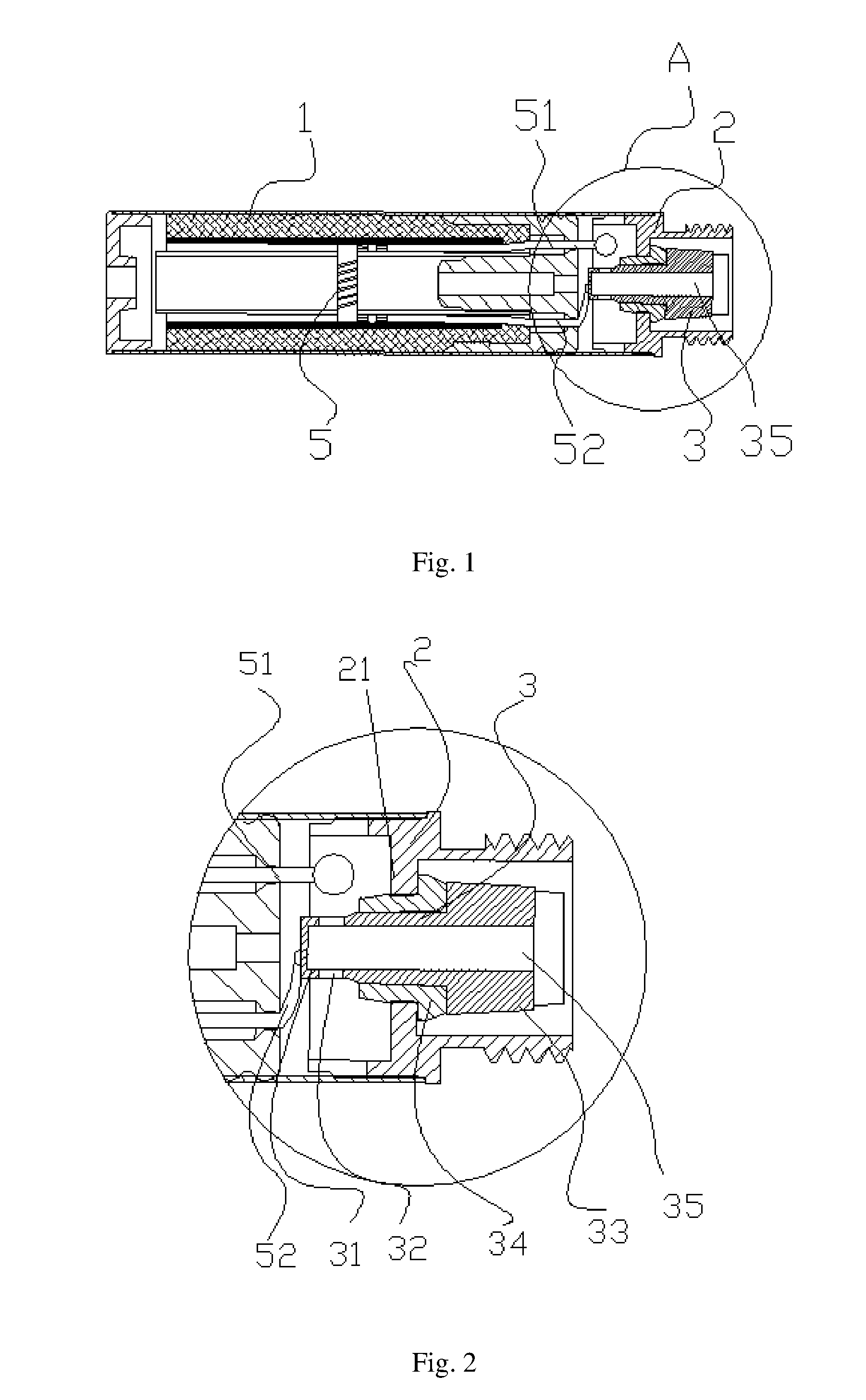

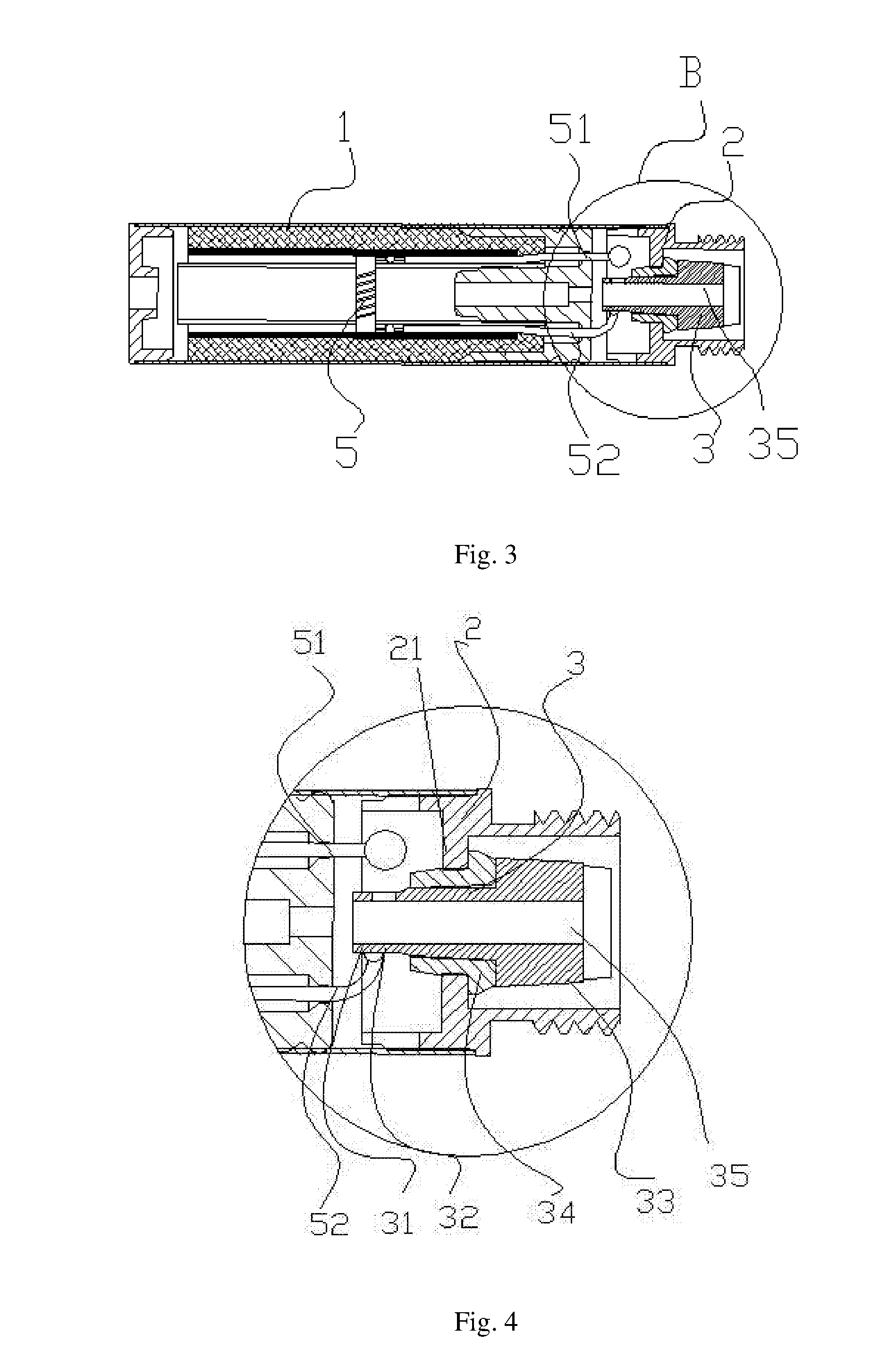

[0044]As shown in FIGS. 1-4, the second lead wire 52 is connected to the extension part 31 by means of soldering.

[0045]Implementing Method One: As shown in FIGS. 1-2, an end face of the extension part 31 is closed, and the second lead wire 52 is soldered to the end face of the extension part 31. At this time, since the second lead wire 52 is soldered to the end face of the extension part 31, and the first through-hole 32 is defined on a side face of the extension part 31, a clogging of the ventilation hole will not occur since the soldering tin is at a large distance from the first through-hole 32. Preferably, in this case, there are two first through-holes 32.

[0046]Implementing Method Two: As shown in FIGS. 3-4, the first air channel 35 runs through two ends of the second electrode 3. The second lead wire 52 is soldered on the side face of the extension part 31, and the second lead wire 52 and the first through-hole 32 are staggered from each other. In this case, a clogging of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com