Device and method for a rail vehicle

a technology for rail vehicles and testing devices, applied in the direction of mechanically controlled devices, transportation and packaging, brake systems, etc., can solve the problems of large difficulty, high cost, unattractive attachment mechanisms, etc., and achieve the effect of increasing the weight of the payload and increasing the bending stress of the sha

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

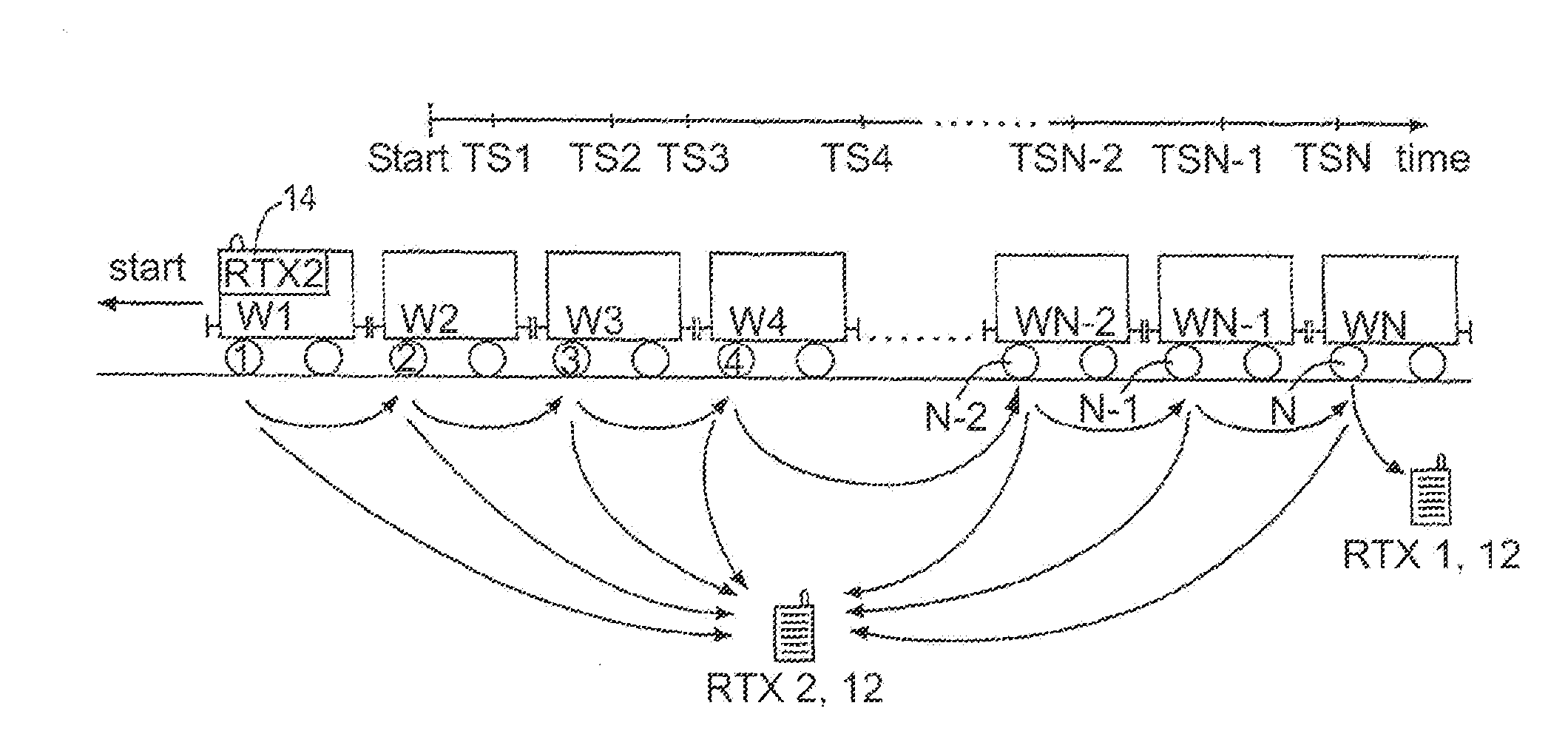

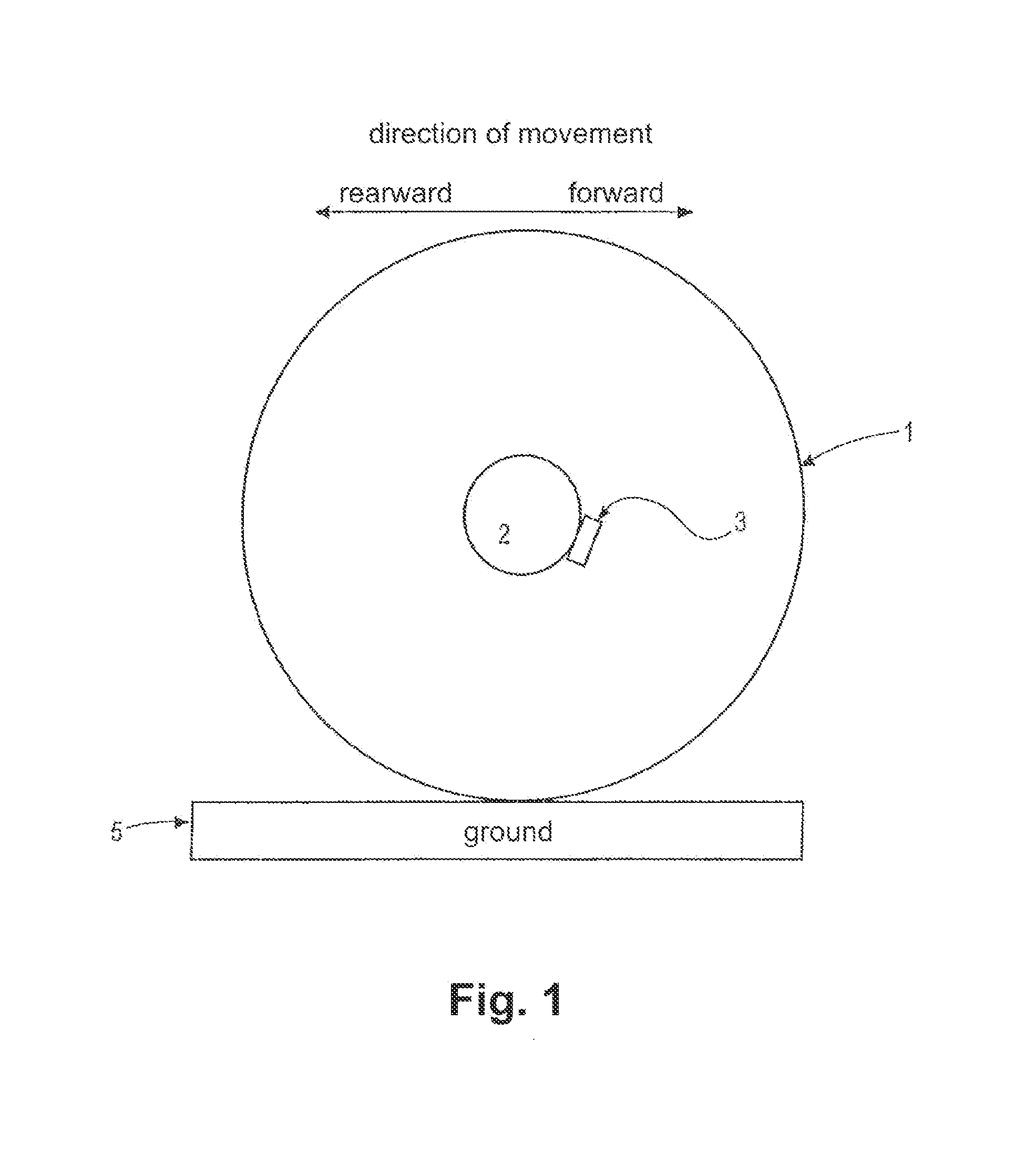

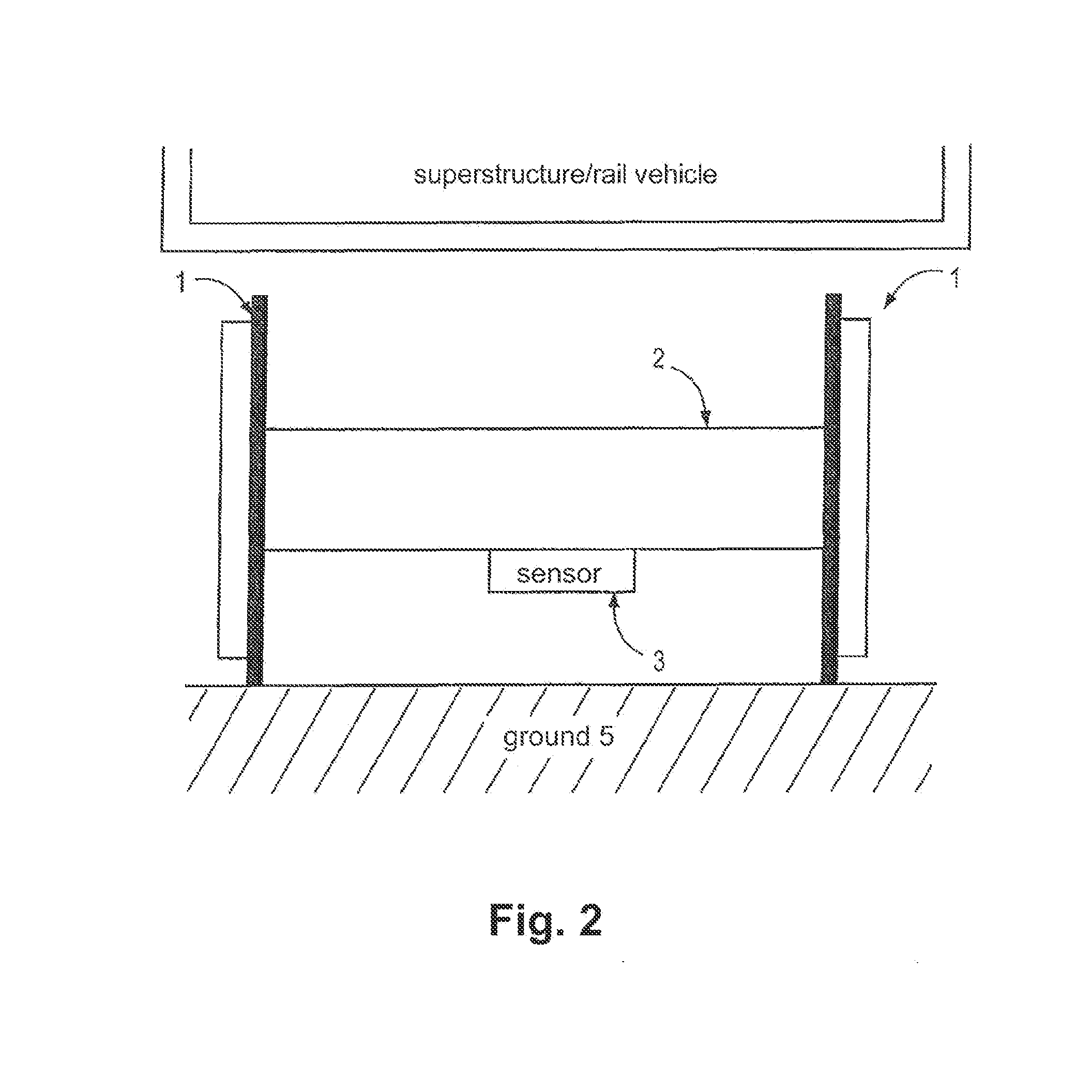

[0118]FIG. 1 shows a simplified representation of a section of an embodiment of a device according to the invention. A wheel 1, for example of a rail vehicle with a superstructure (not shown), is represented. A vehicle axle or the shaft 2 of a vehicle axle (in the context of the present invention often simplifying only referred to as shaft) is attached to the wheel 1, which protrudes into the image plane such that only its cross-sectional area is represented. The shaft 2 can typically connect two similar wheels 1 of the rail vehicle. A device 3 is disposed on the shaft 2, which can be configured according to different aspects of the invention described herein. Quite generally, the device is disposed on the shaft instead of other locations of the rail vehicle. The wheel 1 rolls over the ground 5, which can for example be a rail, upon forward or rearward movement of the rail vehicle. In the device 3, very different sensors, for example a microprocessor, a memory, in particular semicon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com