Lid for a drinking container

a drinking container and lid technology, applied in the field of lids, can solve the problems of insufficient tightness of the rubber lid with the sealing member, the inability to seal the drinking hole, and the small drinking hole of the plastic flat lid to have a sealing function, etc., to prevent or minimize finger touch, and facilitate the effect of disconnecting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

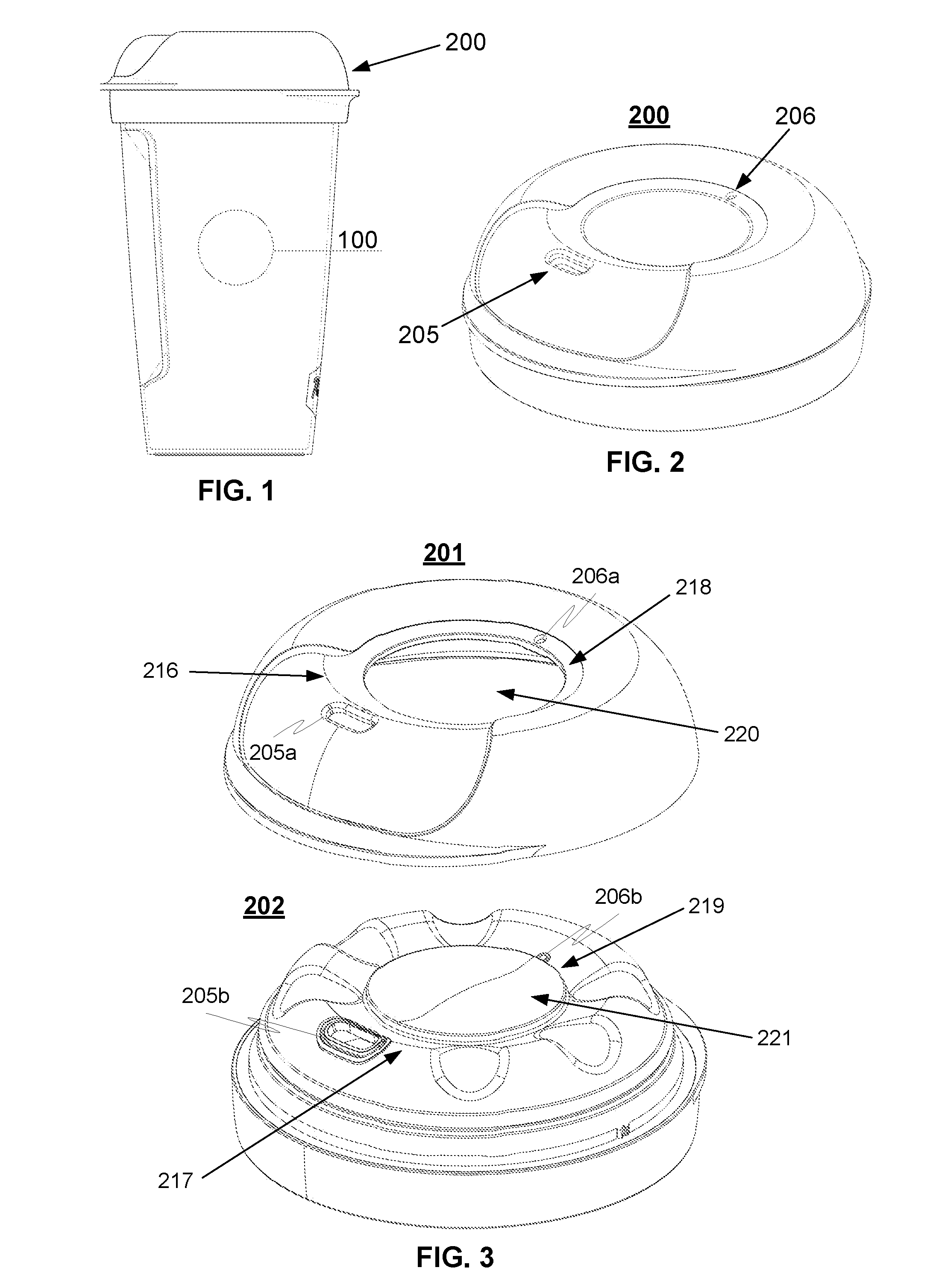

[0029]FIG. 1 illustrates a principle of an exemplary drinking container 100 with a lid 200 according to an advantageous embodiment of the invention. The typical drinking container 100 is e.g. a coffee or tea mug, but can of course be any drinking container capable of carrying liquid inside and with which the lid 200 can be used for preventing any leakage or spilling of the liquid.

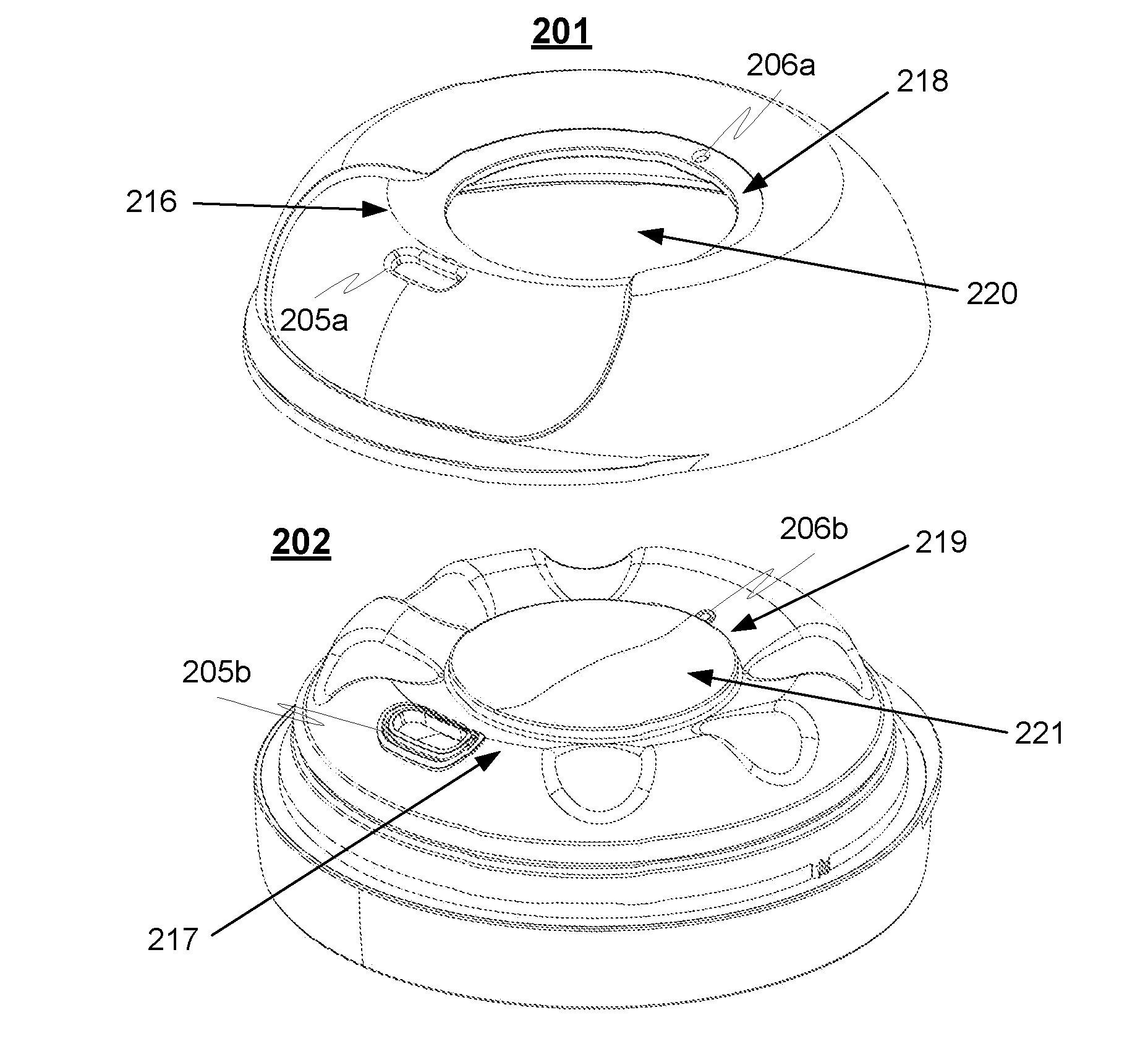

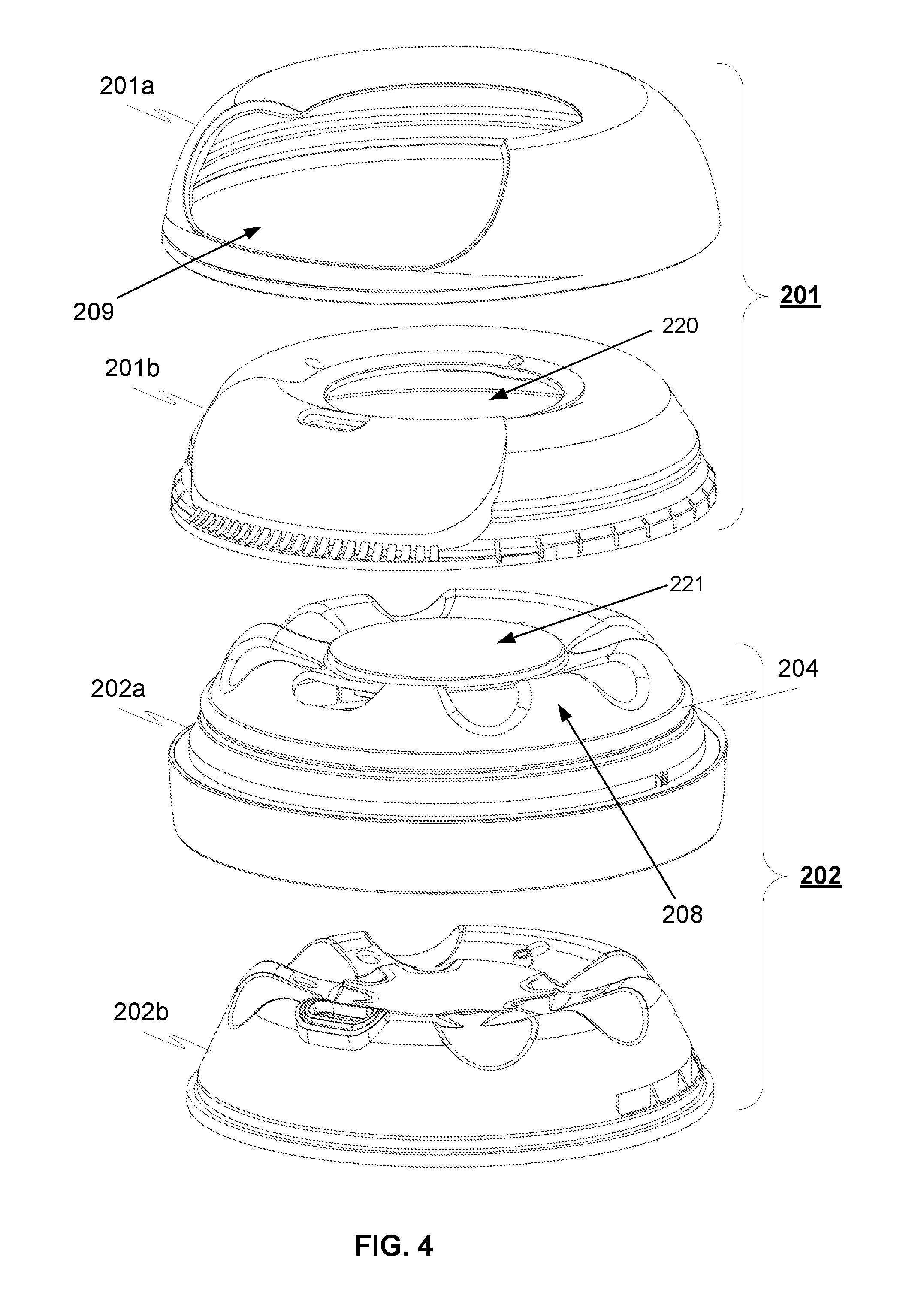

[0030]FIGS. 2-6 illustrate different views of an exemplary lid 200 according to an advantageous embodiment of the invention, where in FIG. 2 the lid is assembled for use mode, and where in FIG. 3 the lid is divided into the circular upper portion 201 and circular lower portion 202 from which the lid is formed. In addition FIG. 4 illustrates an exemplary lid structure, where at least the circular lower portion 202 comprises two parts 202a, 202b, and additionally and optionally also the circular upper portion comprises two parts 201a, 202b. FIG. 5 illustrates a cross section figure of the circular upper porti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| circumference | aaaaa | aaaaa |

| shape | aaaaa | aaaaa |

| hard | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com