Multi-stage centrifugal compressor and air conditioning unit

a centrifugal compressor and air conditioning technology, which is applied in the direction of machines/engines, liquid fuel engines, light and heating apparatus, etc., can solve the problems of affecting the reliability of operation, affecting the overall production cost and maintenance cost of the unit, and the requirement of material strength of the impeller, etc., to achieve high efficiency and stably operation, the effect of multi-stage centrifugal compressor and high pressure ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039]In order to solve the problem of too low pressure ratio, a multi-stage centrifugal compressor and an air conditioning unit are provided.

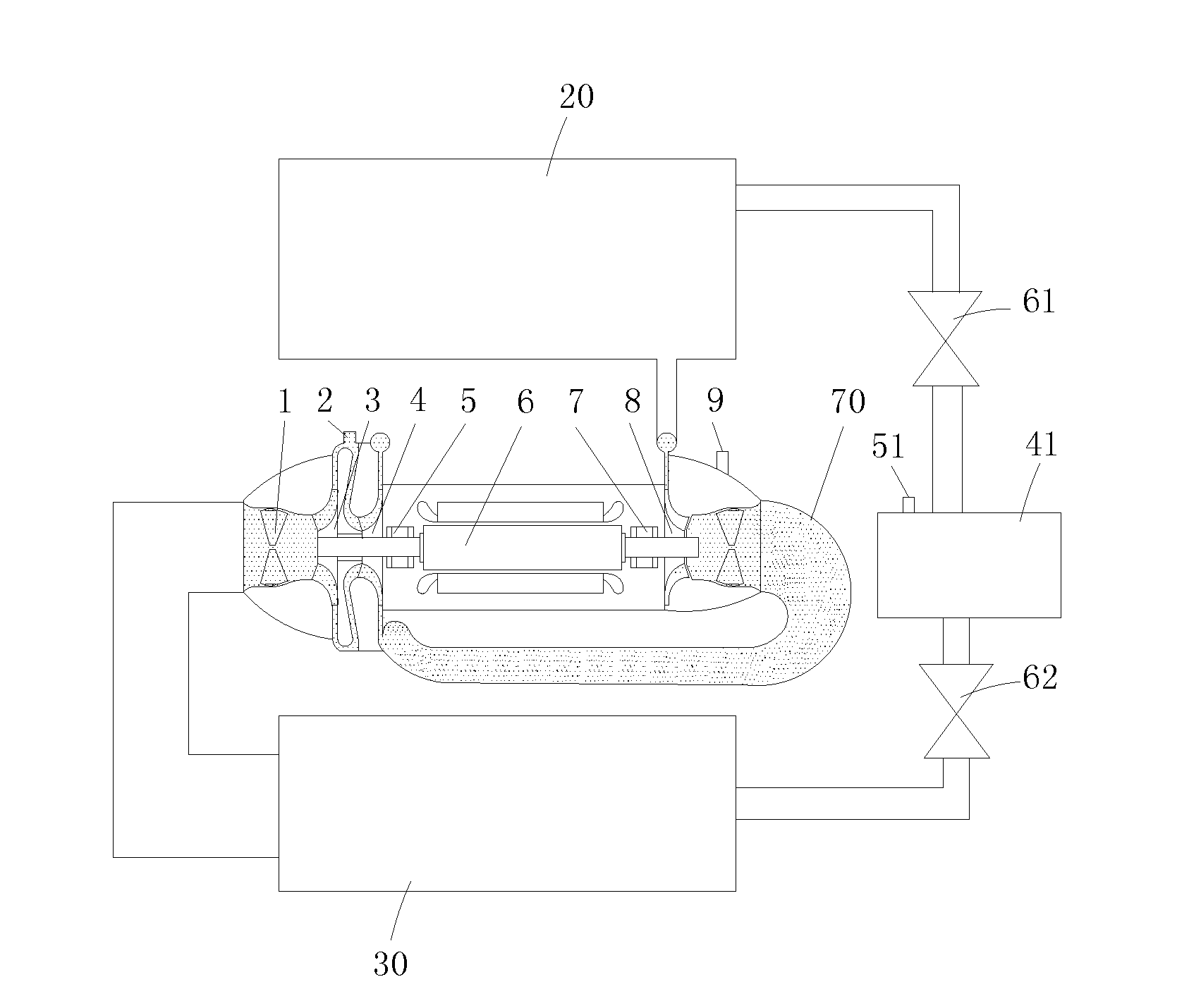

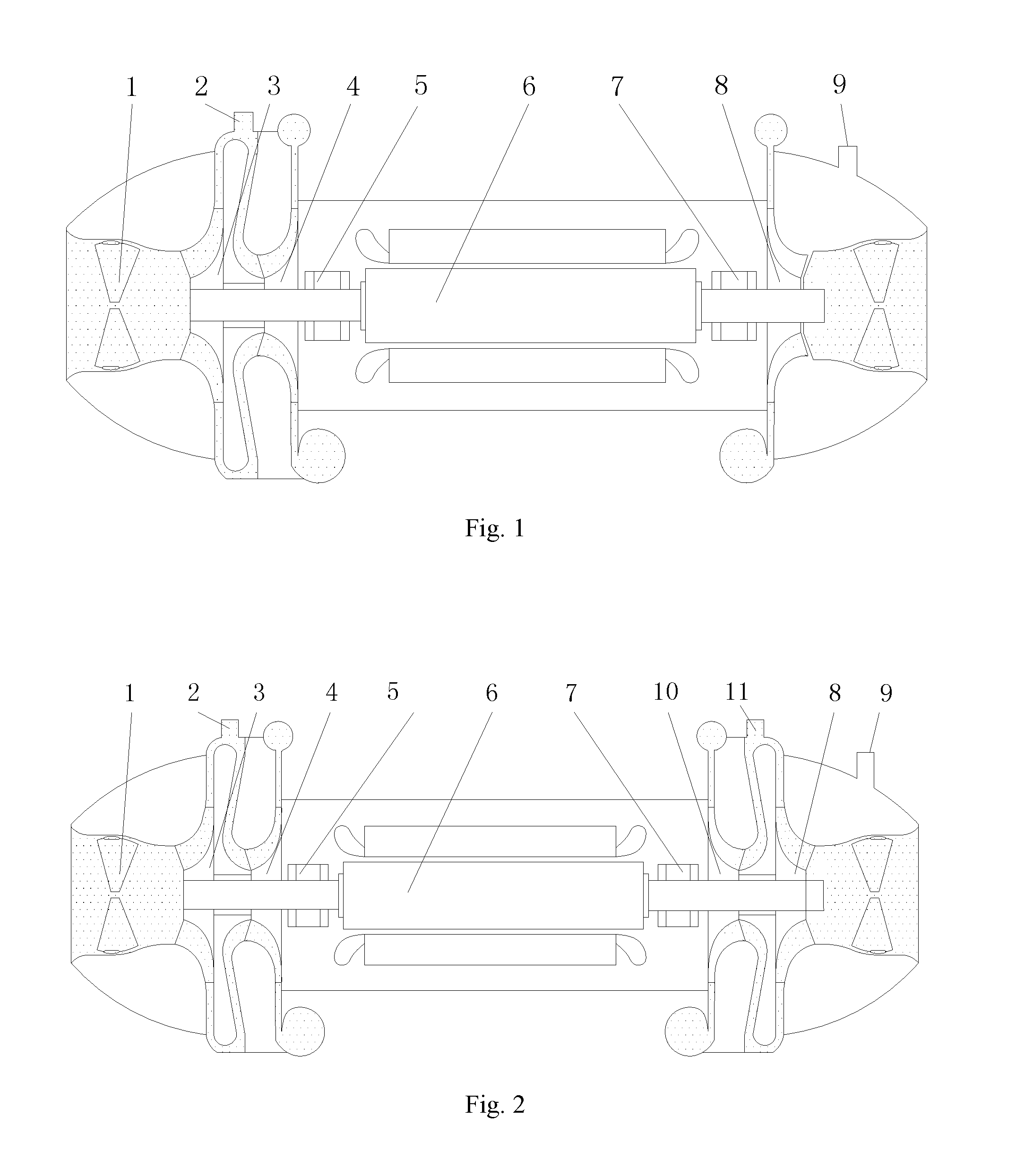

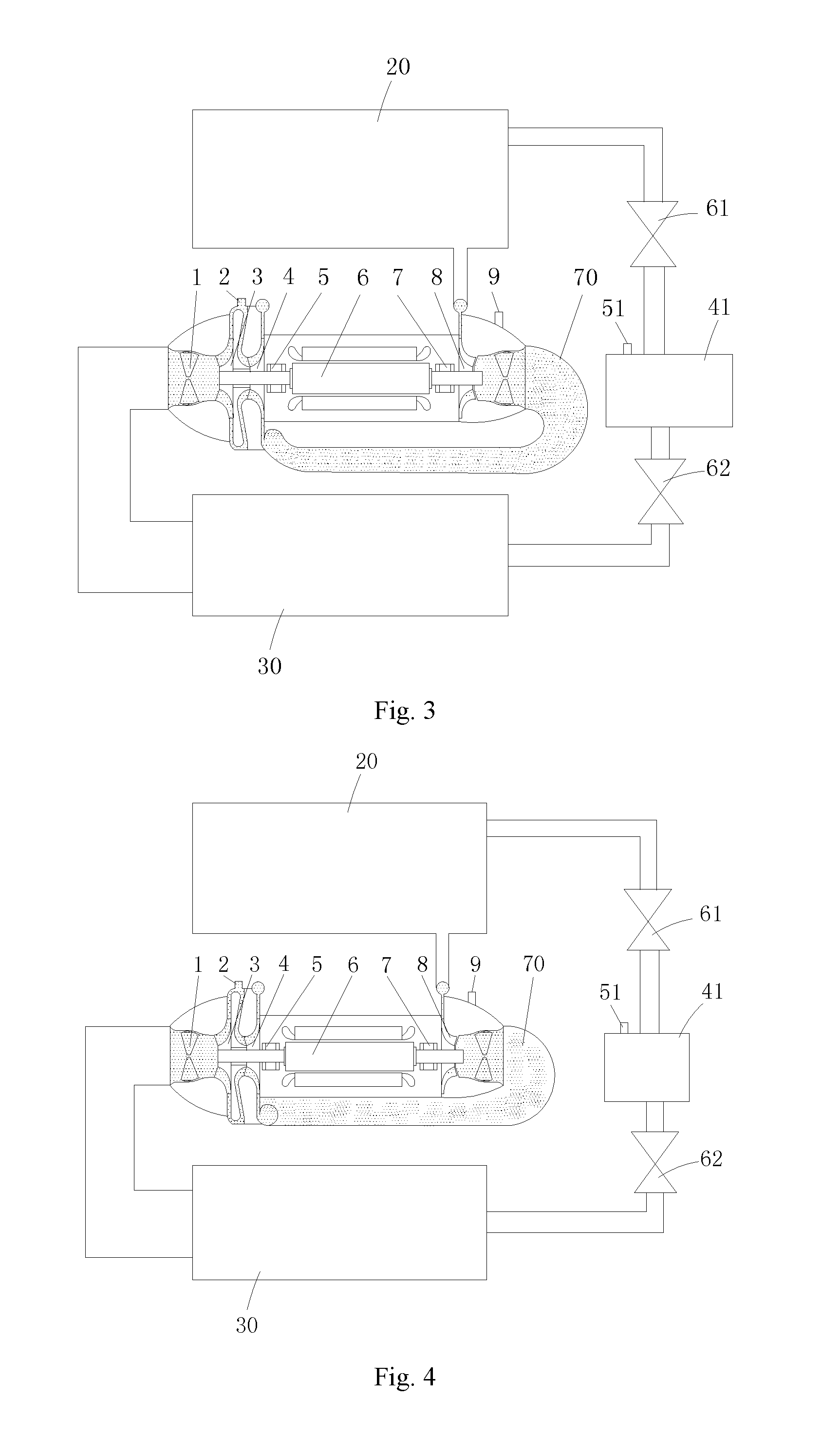

[0040]The present disclosure provides a multi-stage centrifugal compressor, comprising a power portion and an impeller portion. The power portion comprises a motor having a shaft. The shaft of the motor comprises a first end and a second end;

[0041]The impeller portion comprises N impellers, wherein N is equal to or more than 2 and less than 10;

[0042]When N is an even, the number of the impellers on the first end of the shaft is equal to that of the impellers on the second end of the shaft;

[0043]When N is an odd, the number of the impellers on the first end of the shaft is one more than that of the impellers on the second end of the shaft;

[0044]The first stage impeller farthest away from the motor is arranged at the first end of the shaft; other impellers at the first end of the shaft are arranged in an ascending order;

[0045]The Nth stage impel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com