Look ahead pore pressure prediction

a pore pressure prediction and pore pressure technology, applied in the direction of survey, directional drilling, borehole/well accessories, etc., can solve the problem of compromising the resistivity measurement within the neighboring shale, and achieve the effect of low resistance value, good results and salinity increas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

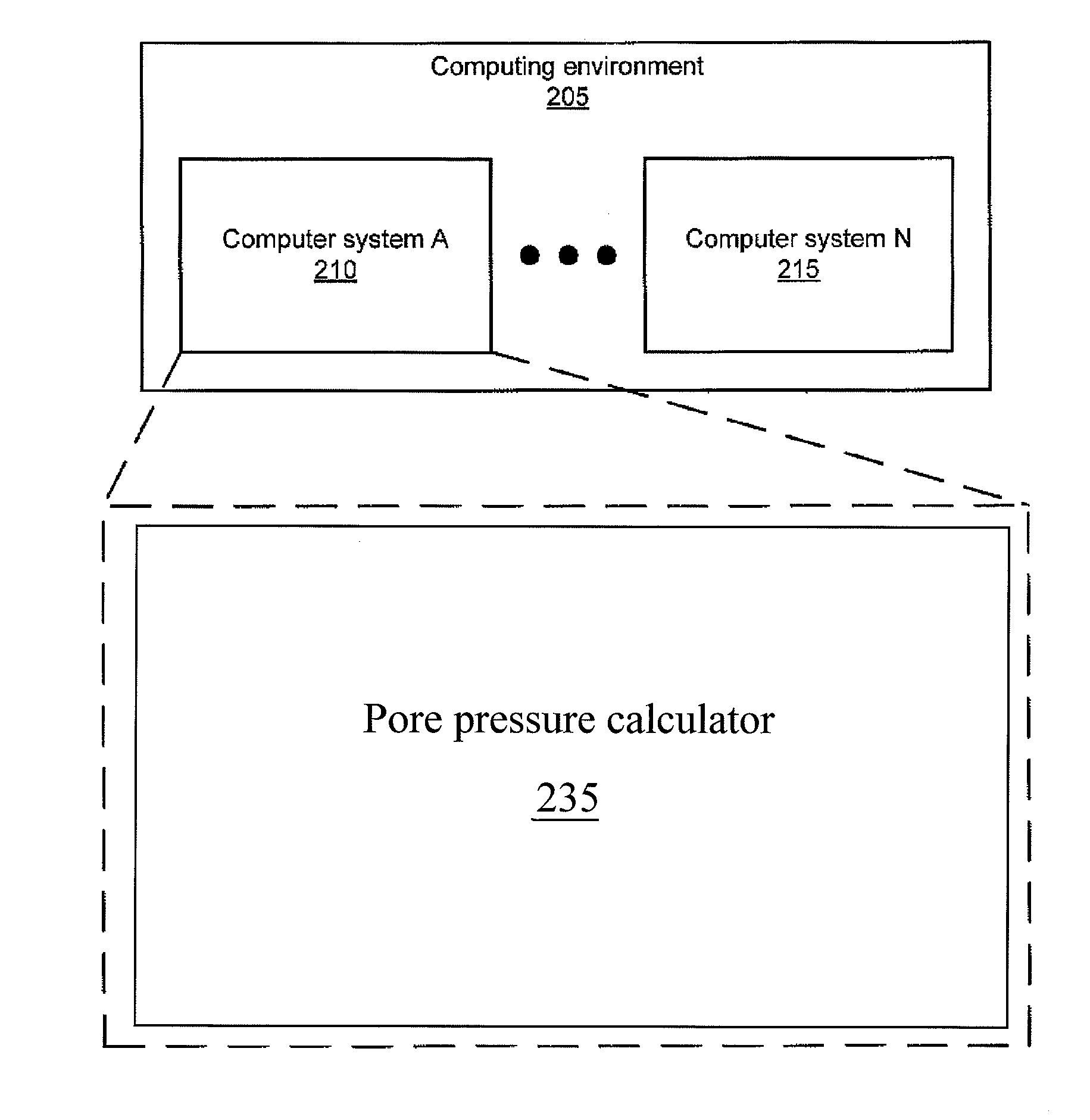

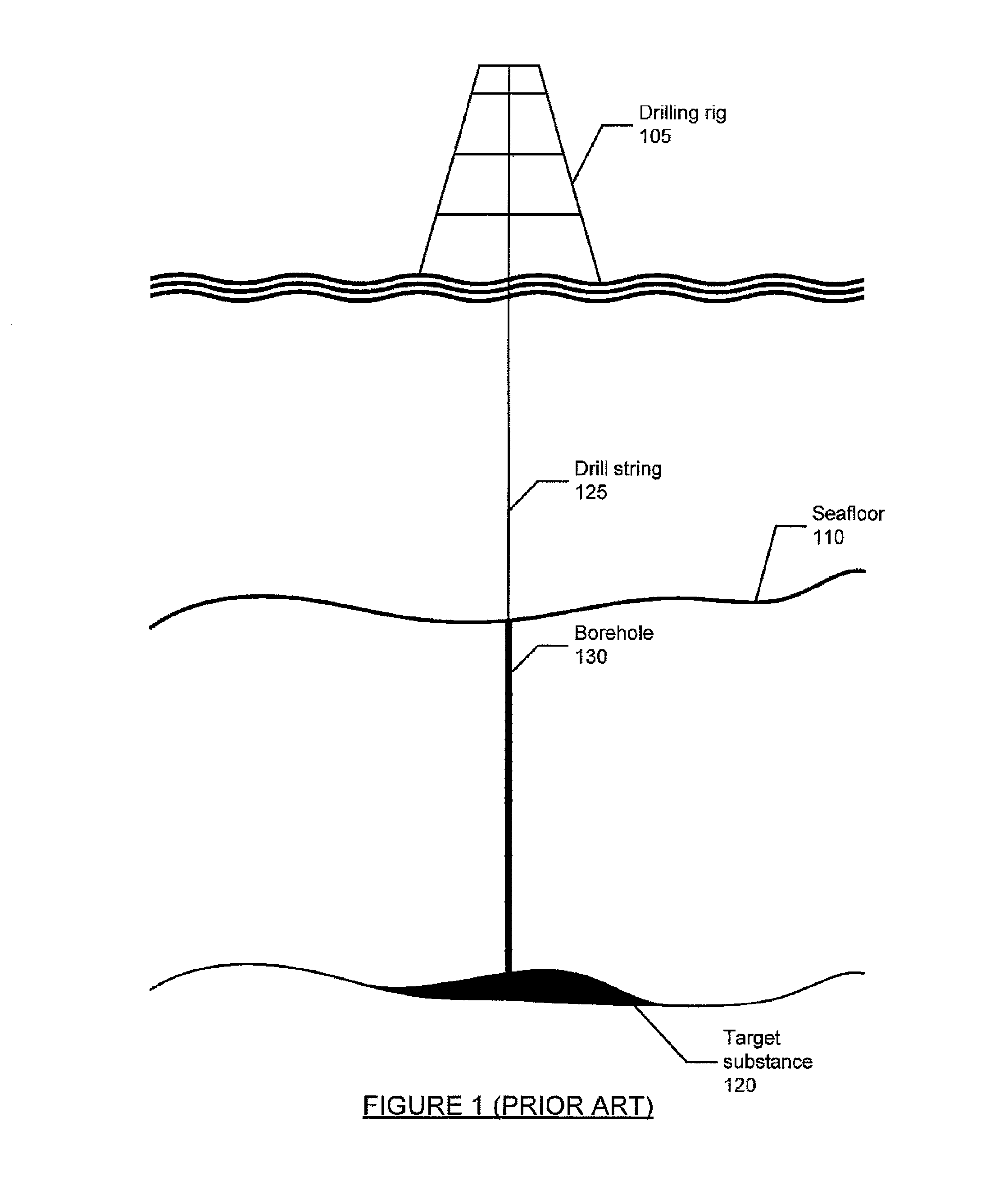

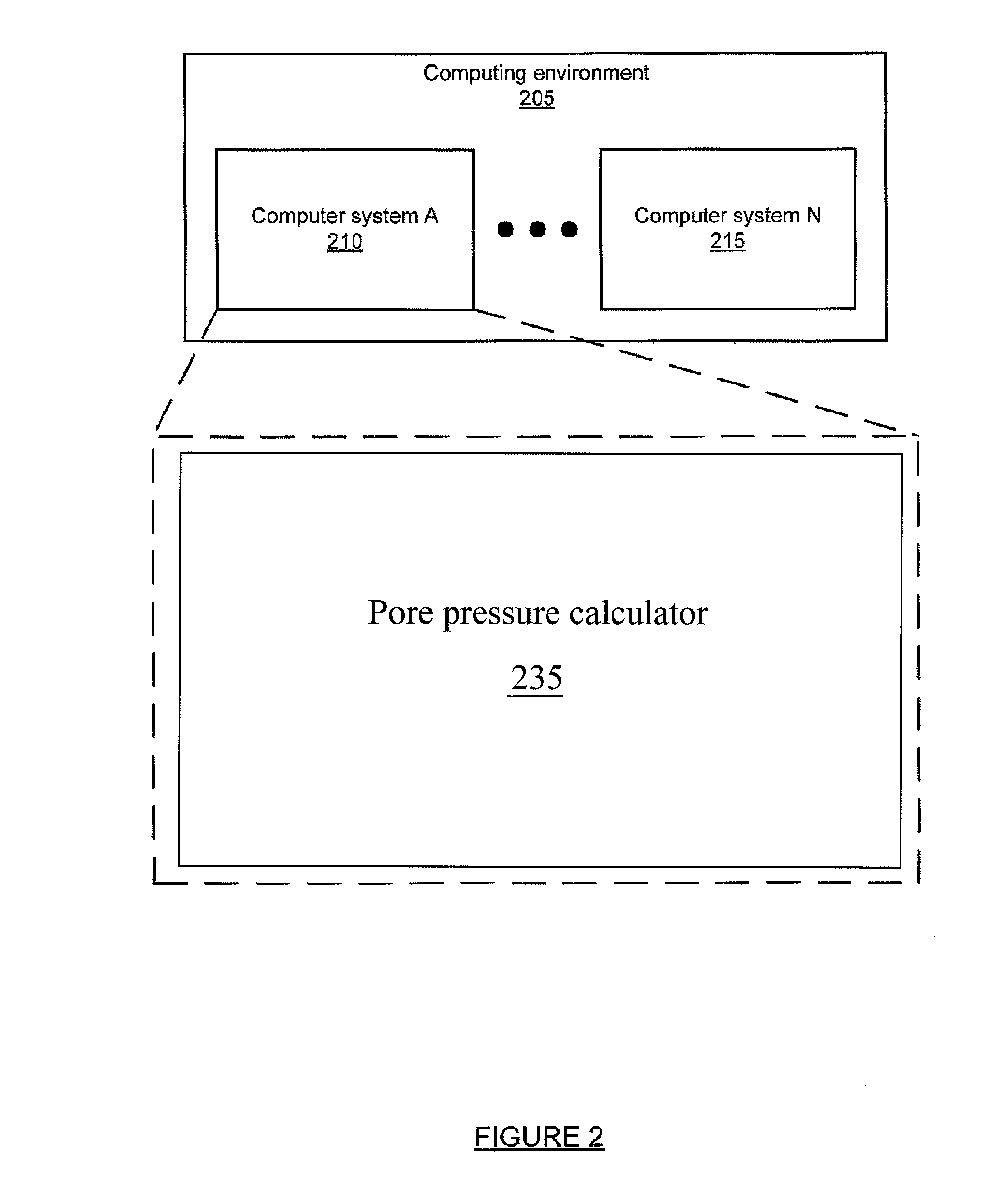

[0023]The present invention will now be described with reference to the accompanying drawings.

[0024]The present invention is directed to a predictable relationship between resistivity and porosity (derived from density) that occurs up to 300 meters above an overpressured sandstone in the overlying shales. Because high overpressure from a sand body is communicated to the shale above, a variation from the normal trend of the resistivity / porosity (or any other combination of variables, like resistivity and velocity) field is expected when approaching the high overpressured sand.

[0025]The present invention is also directed to a two-warning system based on this information. First, an early warning alerts that there is an overpressured region below. Then, a second warning occurs when the overpressured layer is approaching in order to better locate it.

[0026]As a drill bit drills, porosity and resistivity are measured and plotted on a graph with porosity on the x-axis and resistivity on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com