Candy Manufacturing Support Pallet and Method of Use

a technology of candy manufacturing and support pallets, which is applied in the direction of packaging foodstuffs, shock-sensitive articles, packaged goods types, etc., can solve the problems of difficult support of candy canes, fragile candy canes, and odd shapes, and achieve the effect of convenient movement and storag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

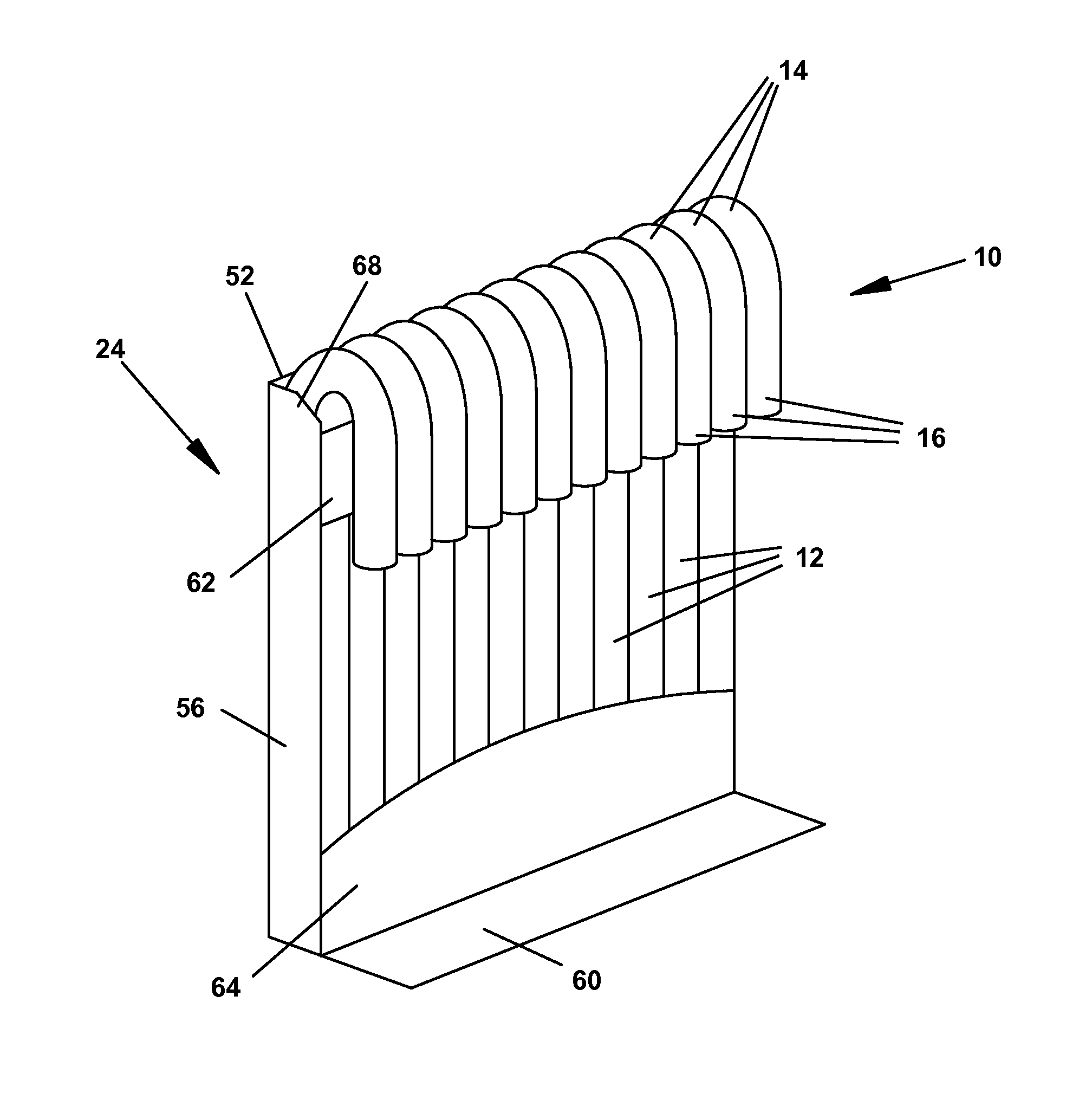

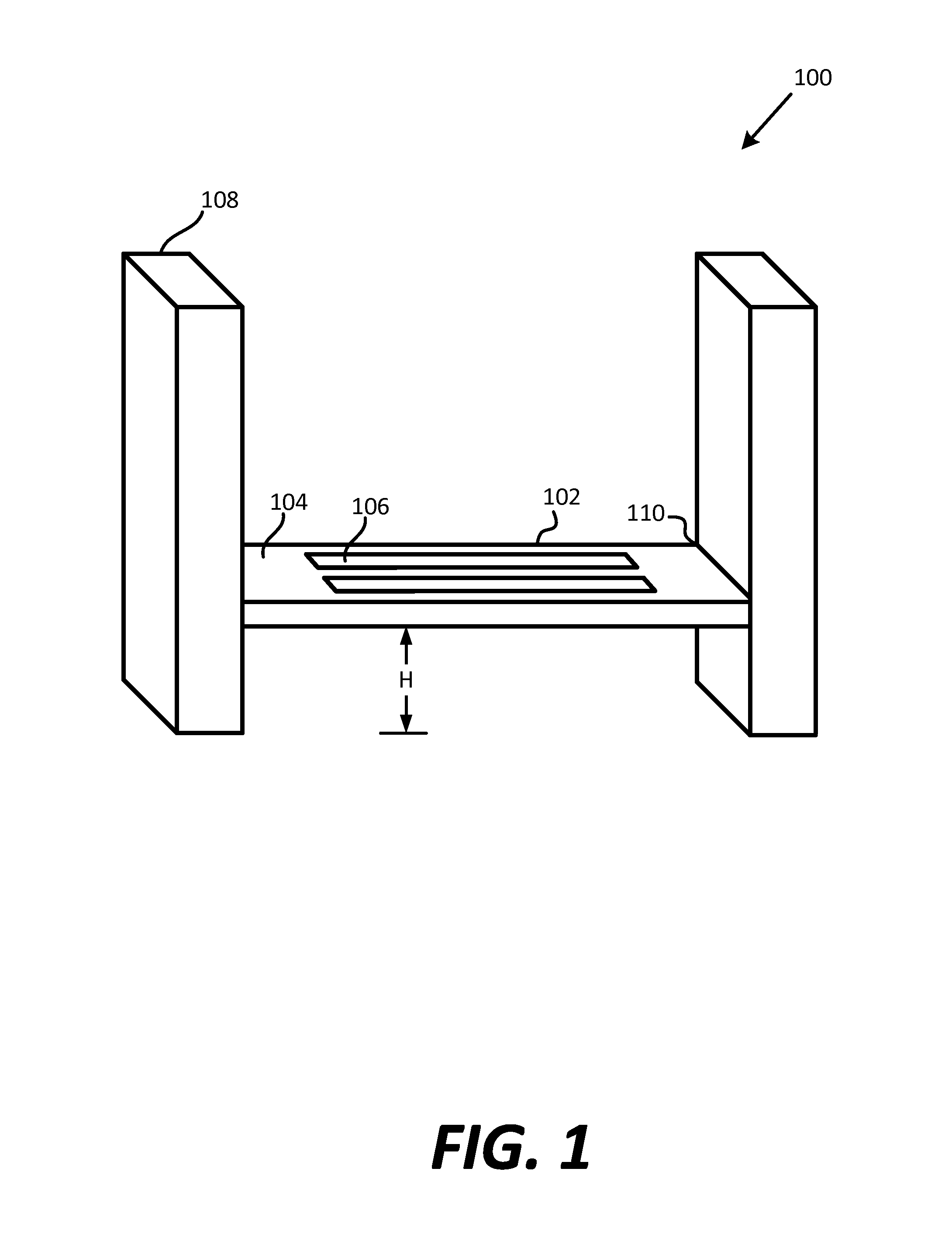

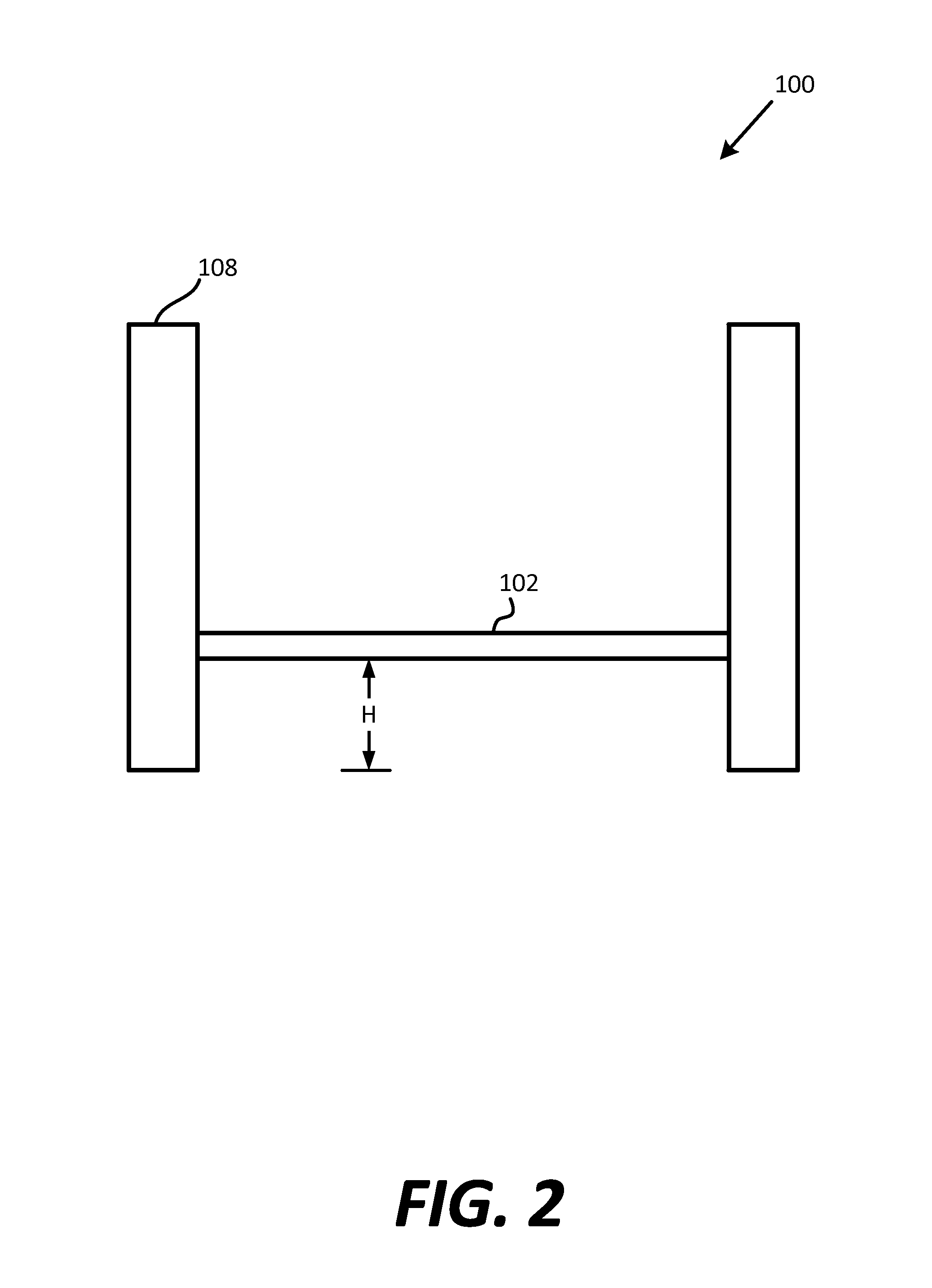

[0021]As briefly described above, embodiments of the present invention are directed to a candy product manufacturing support system, as well as a method for its use. In general, the system described herein includes a manufacturing support pallet that provides a holding structure to store candy products such as candy canes before the packaging is finalized. Although used between the manufacture of the product and the finalization of the packaging, it is within the scope of this disclosure to additionally use the support pallet during shipping and / or display of the finalized product.

[0022]As mentioned above, candy canes are generally brittle, easily broken and awkwardly shaped for storage and handling purposes. The use of the support pallet can enable the production of the candy canes at a convenient time based on the manufacturer's preferences and availability. In some circumstances, the manufactured candy canes can sit on the support pallet for weeks, months or longer before being p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com