Shock absorber

a technology of shock absorber and shock absorber, which is applied in the field of shock absorbers, can solve the problems of difficult to suppress vibration at a frequency higher than several hz, and achieve the effect of improving riding comfort in the vehicle, not sacrificing the stroke length of the shock absorber, and not impaired mountability in the vehicl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0030]First, a shock absorber D1 according to a first embodiment of the present invention will be explained.

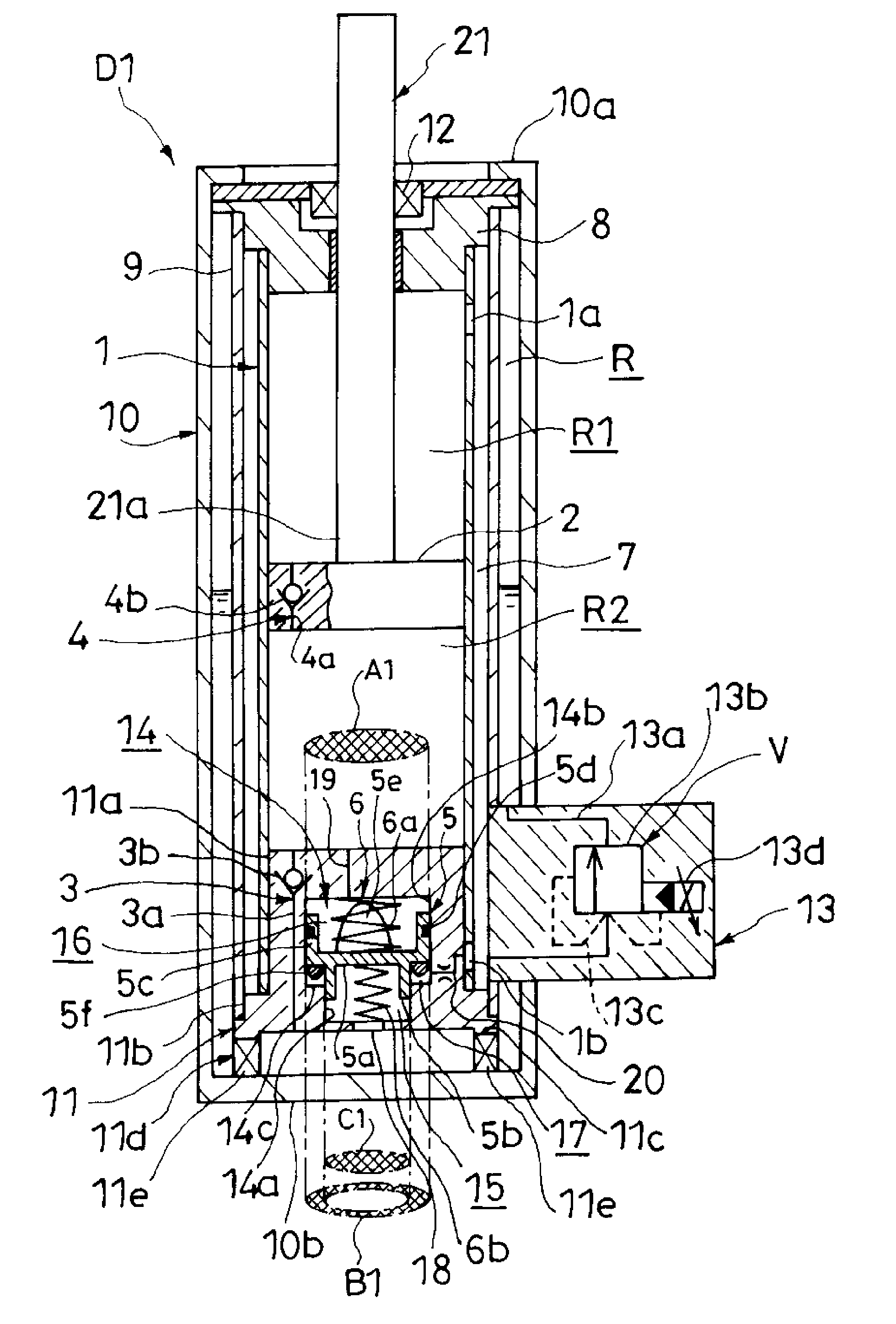

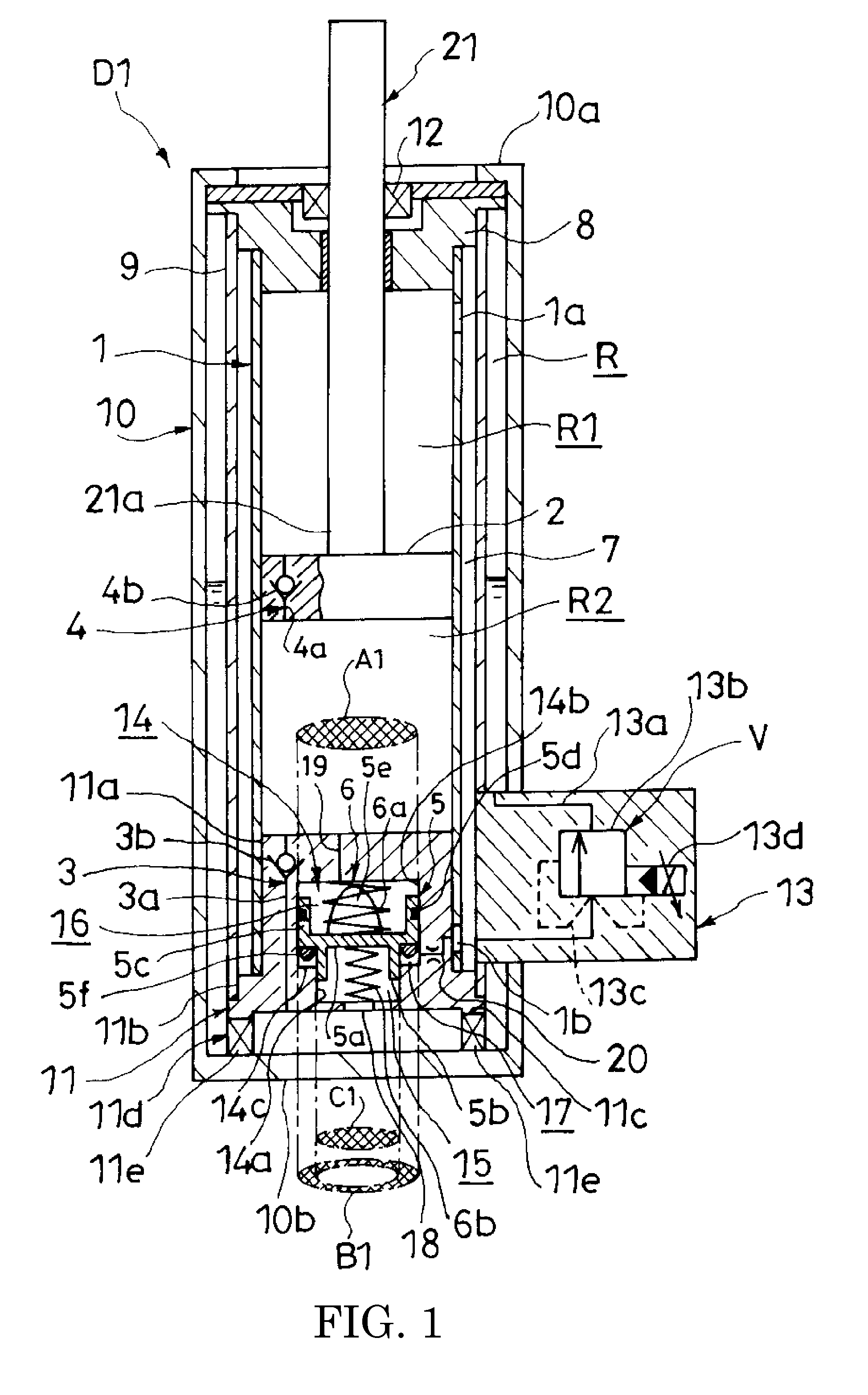

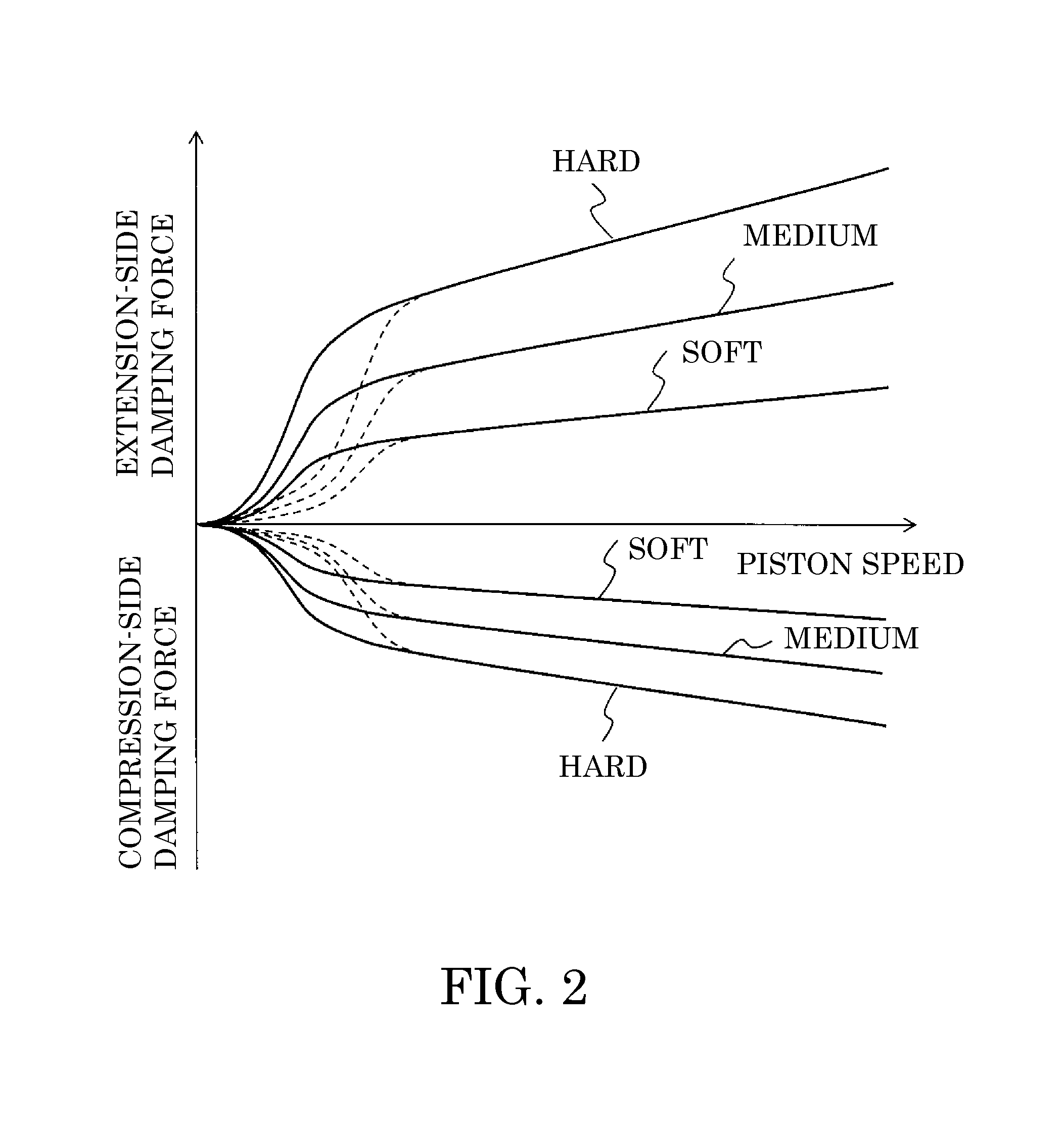

[0031]As shown in FIG. 1, the shock absorber D1 has a tubular cylinder 1, a piston 2 that is slidably inserted into the cylinder 1 and partitions the inside of the cylinder 1 into two chambers which are an extension-side chamber R1 and a compression-side chamber R2, a reservoir R, a suction passage 3 that permits only a flow of working oil from the reservoir R toward the compression-side chamber R2, a rectification passage 4 that permits only a flow of working oil from the compression-side chamber R2 toward the extension-side chamber R1, a damping force variable valve V serving as a damping force adjusting part that permits only a flow of working oil from the extension-side chamber R1 toward the reservoir R and can change a resistance applied to the flow of working oil, a bottom member 11 serving as a housing that has a pressure chamber 14 therein, a free piston 5 that is slid...

second embodiment

[0107]Next, a shock absorber D2 according to a second embodiment of the present invention will be explained in FIG. 5.

[0108]In the shock absorber D2, the reservoir R communicates with the outer periphery chamber 17, and the extension-side chamber R1 communicates with the small chamber 15 through an orifice passage 30. The shock absorber D2 differs from the shock absorber D1 in this point, but in all other points it is the same as the shock absorber D1. Hereinafter, constitutions that are the same as those in the shock absorber D1 will be assigned the same reference numerals in the drawings and detailed explanations thereof will be omitted.

[0109]The small chamber 15 communicates with the extension-side chamber R1 through the orifice passage 30, the through-hole 1b formed in the cylinder 1, and the discharge passage 7. The outer periphery chamber 17 communicates with the reservoir R through a passage 31 formed in the bottom member 11. The large chamber 16 communicates with the compres...

third embodiment

[0169]Next, a shock absorber D3 according to a third embodiment of the present invention will be explained. Hereinafter, constitutions that are the same as those in the first and second embodiments will be assigned the same reference numerals in the drawings and detailed explanations thereof will be omitted, and the following explanations will focus on the points of difference from the first and second embodiments.

[0170]The shock absorber D3 according to the third embodiment differs from the first and second embodiments in that it has a hydraulic cushion mechanism L that suppresses collisions between the bottom member 11 and the free piston 5 instead of a cushion member.

[0171]The shock absorber D3 will be explained below referring to FIG. 10. Hereinafter, the points of difference from the shock absorber D1 shown in FIG. 1 will be the focus of the explanation.

[0172]The hydraulic cushion mechanism L is a variable throttle valve, and is provided in the orifice passage 20 serving as an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com