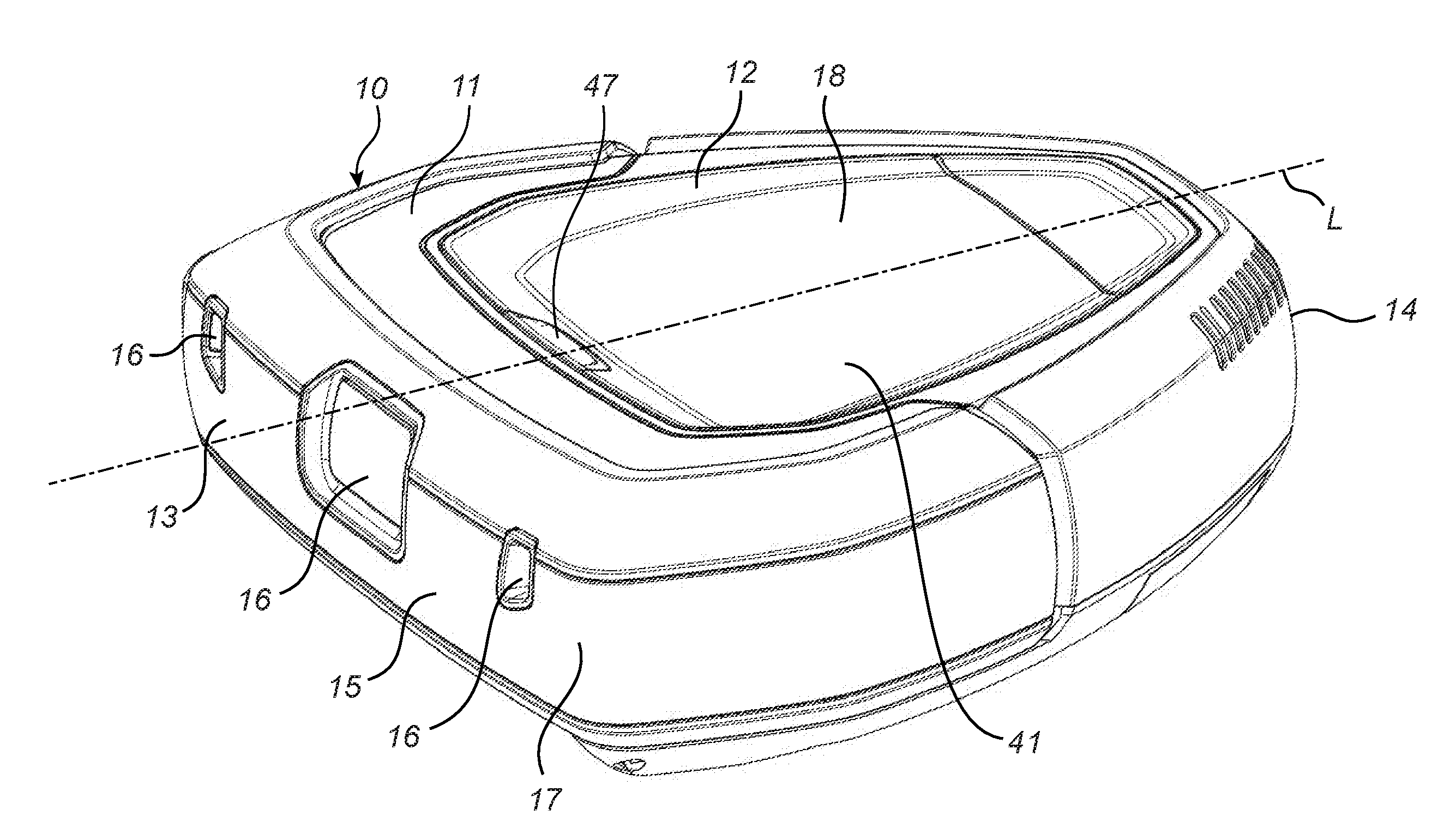

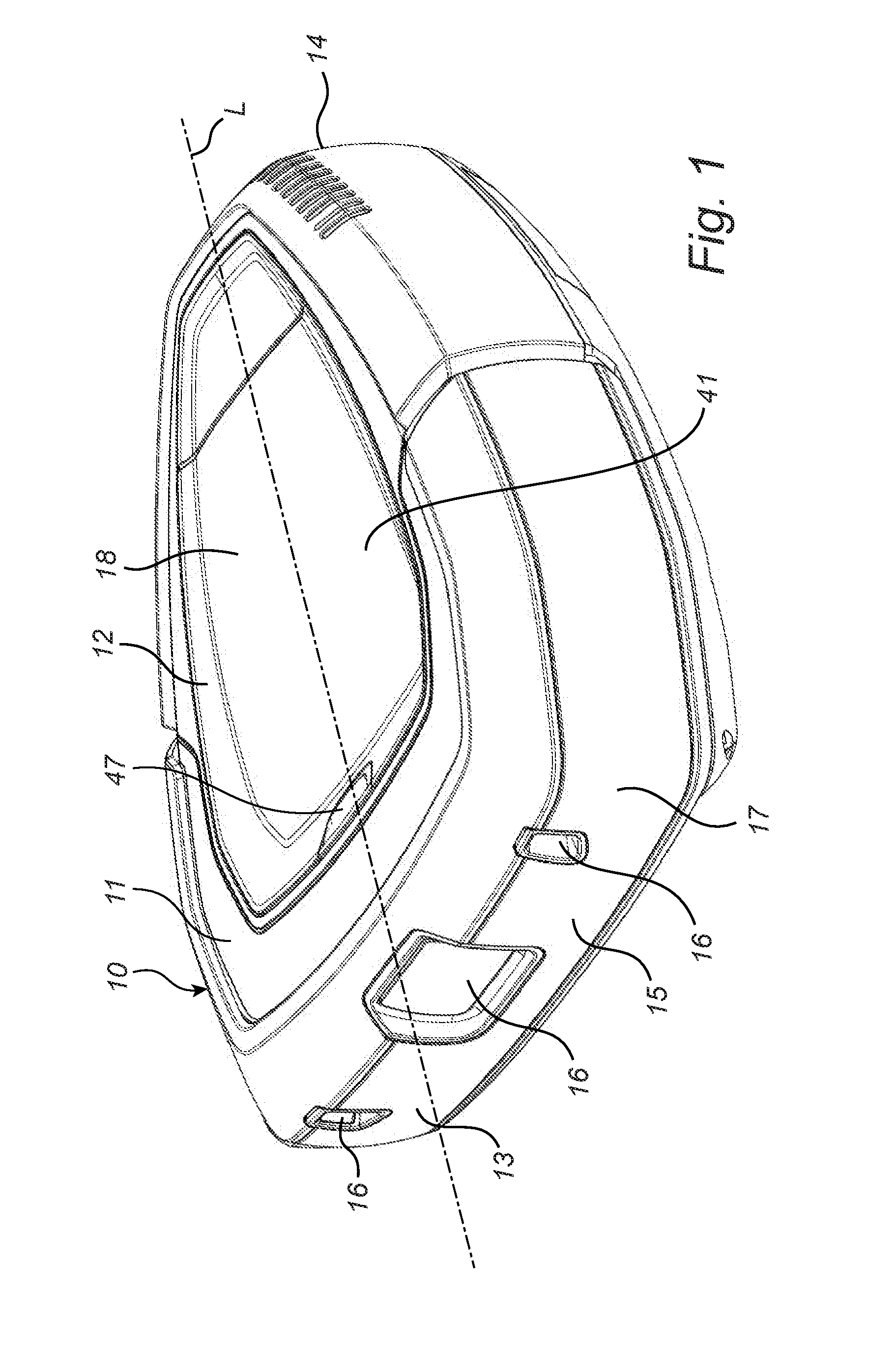

Autononmous cleaner

a cleaner and autonomous technology, applied in the field of autonomous cleaners, can solve the problems of complicated removal and fitting of dust containers in the cleaner body, limited space for the different components, and limited space within the cleaner body, so as to reduce the overall size of the battery pack, facilitate installation, and increase the volume of the dust container.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

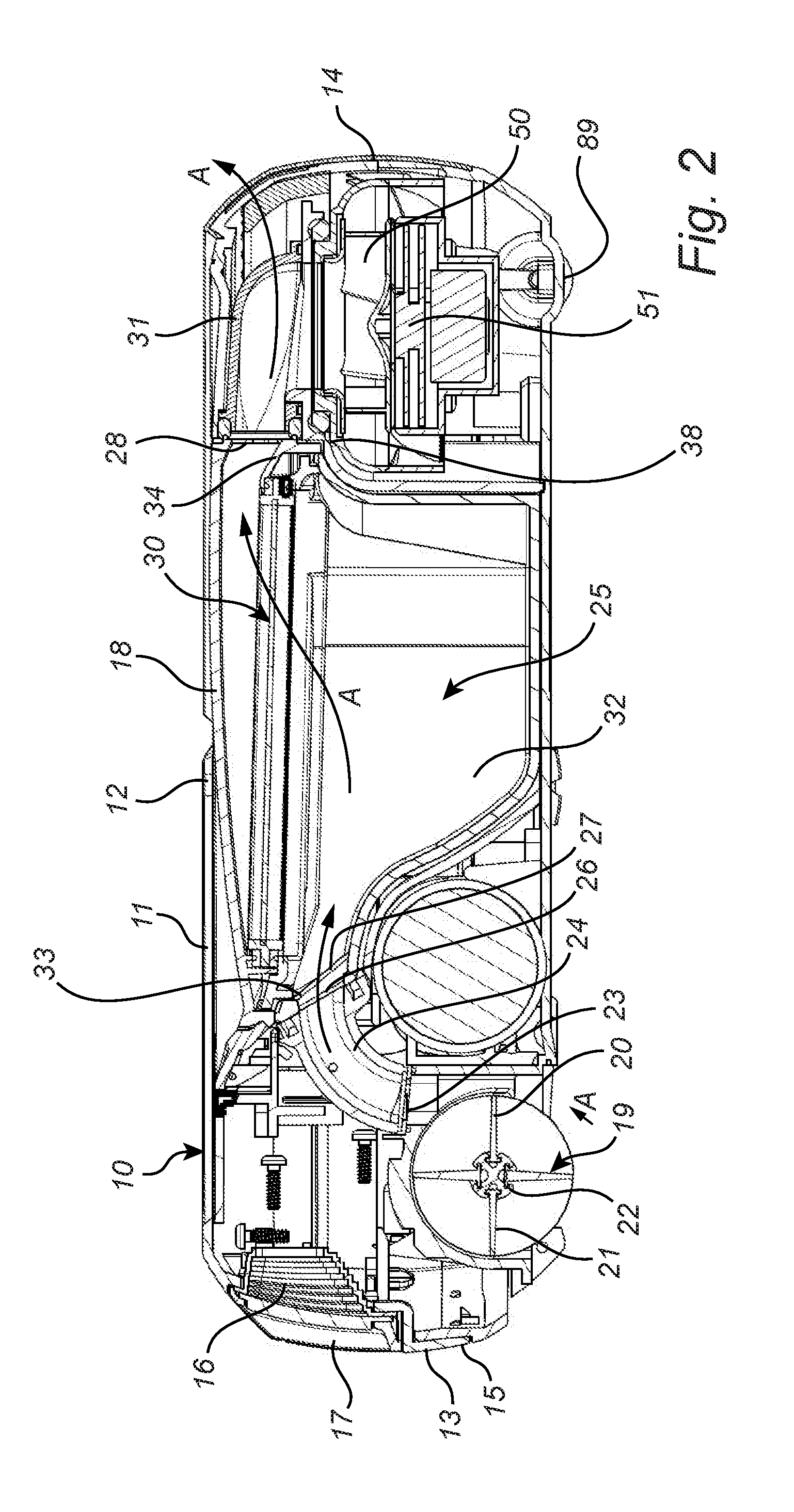

[0047]As described in the summary of the invention, the dust compartment volume is defined as the volume within the dust container usable for particles, debris and dust and the volume of the cleaner body the volume within the cleaner body with the volume of the dust container included in the cleaner body volume.

[0048]For the autonomous cleaner illustrated in the appended figures the following numbers have been determined:

Cleaner body volume 5.15 Liters

Dust compartment volume 0.7 Liters

Ratio =Dust compartment volume / Cleaner body volume =0.7 / 5.15 =0.136

[0049]The dust compartment volume as well as the cleaner body volume will however change if the design of the autonomous cleaner is modified but in order to ensure that the desired extended time period between the required emptying of the dust container and the limited overall size of the autonomous cleaner the ration between the dust compartment volume and the cleaner body volume should be within the range 0.1 to 0.2.

[0050]Furthermore ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com