Defrost chamber within freezer compartment

a freezer compartment and glass technology, applied in the field of freezer compartment defrosting, can solve the problems of foodborne, increased user attention for submerged items in water, inconvenience for individuals, etc., and achieve the effect of improving or overcoming deficiencies in the ar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

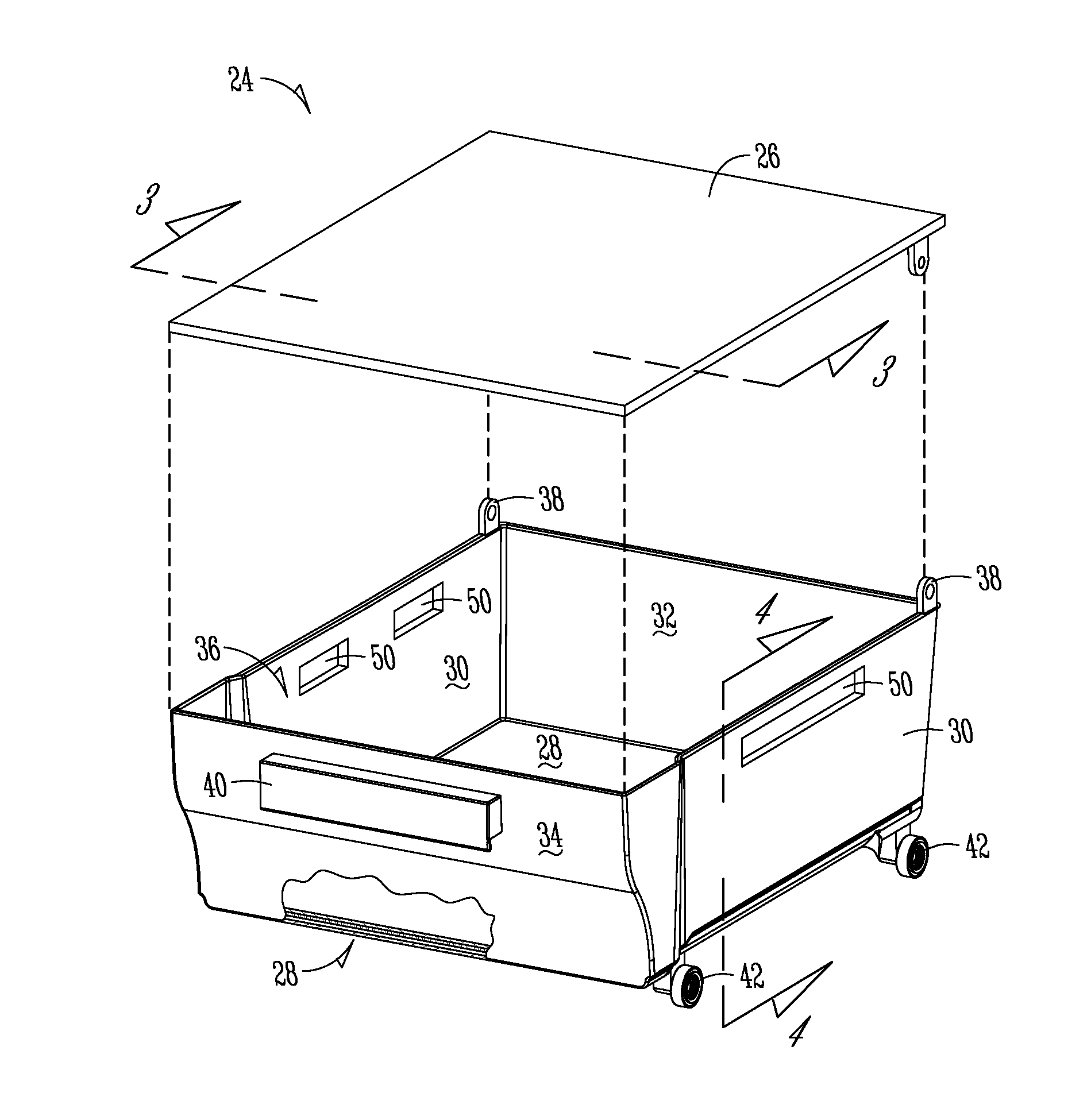

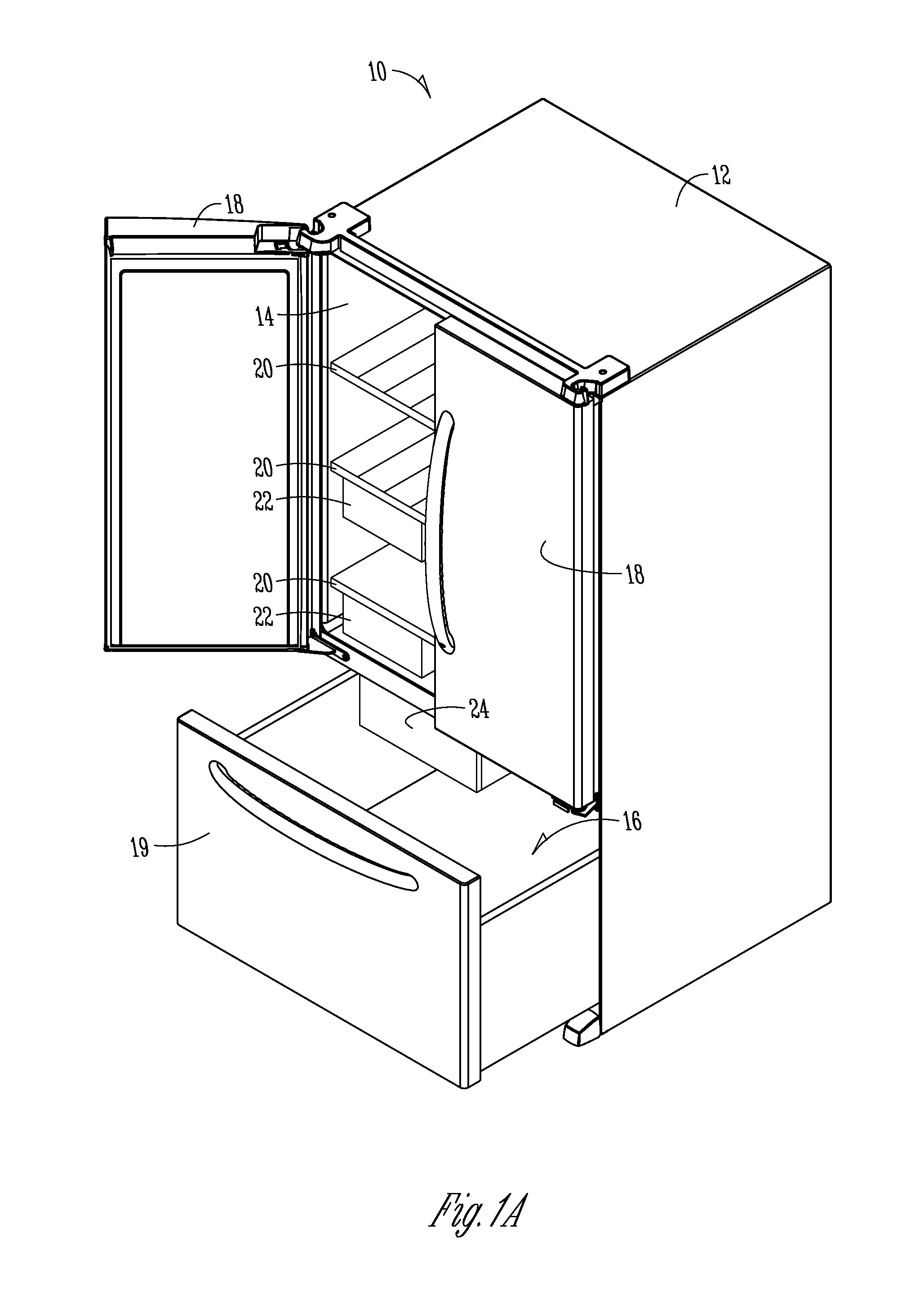

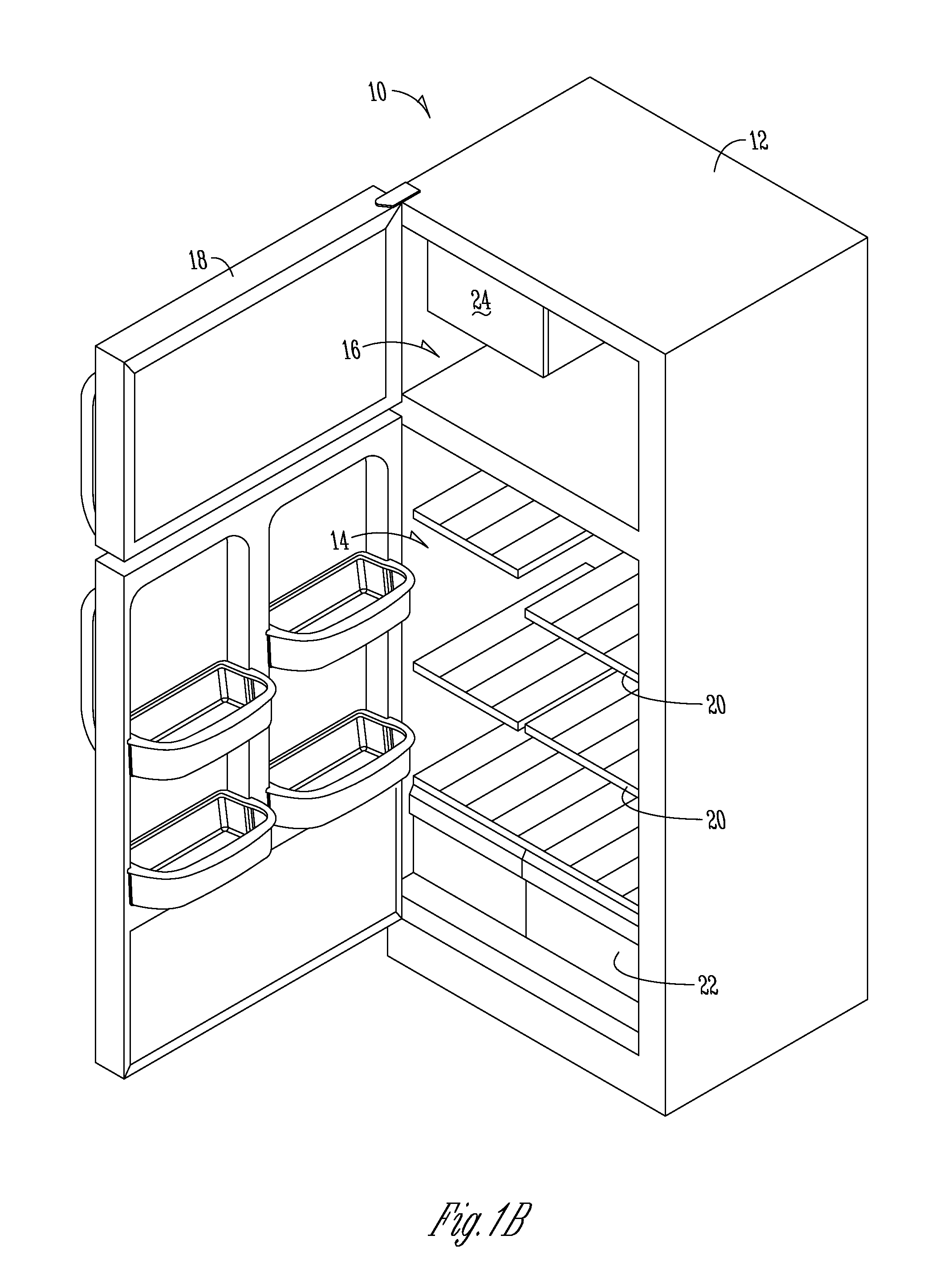

[0032]FIGS. 1A and 1B illustrate refrigerators 10 in accordance with exemplary embodiments of the present disclosure. Each of the refrigerators 10 is comprised of a refrigerator cabinet 12. FIG. 1A illustrates a refrigerator 10 with the fresh food compartment 14 is disposed above the freezer compartment 16, commonly referred to as a “bottom mount” refrigerator. A user may access the fresh food compartment 14 through one or more doors 18. In the exemplary embodiment of FIG. 1A, two French doors are shown. In the bottom mount configuration, a user may access the freezer compartment 16 by slidably opening a drawer 19. FIG. 1B illustrates a refrigerator 10 with the freezer compartment 16 is disposed above the fresh food compartment 16, commonly referred to as a “top mount” refrigerator. In both the bottom mount and top mount configurations, the fresh food section 14 may be comprised of any number of shelves 20 and drawers 22 commonly known in the art. Furthermore, in both the bottom mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com