Liquid storage container with adjustable internal volume

a liquid storage container and internal volume technology, applied in the field of storage containers, can solve the problems of deterioration of the “effervesce” of the soda remaining in the container over a relatively short period of time, negligible amount of carbon dioxide remaining, and difficulty in manual movement of the plunger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

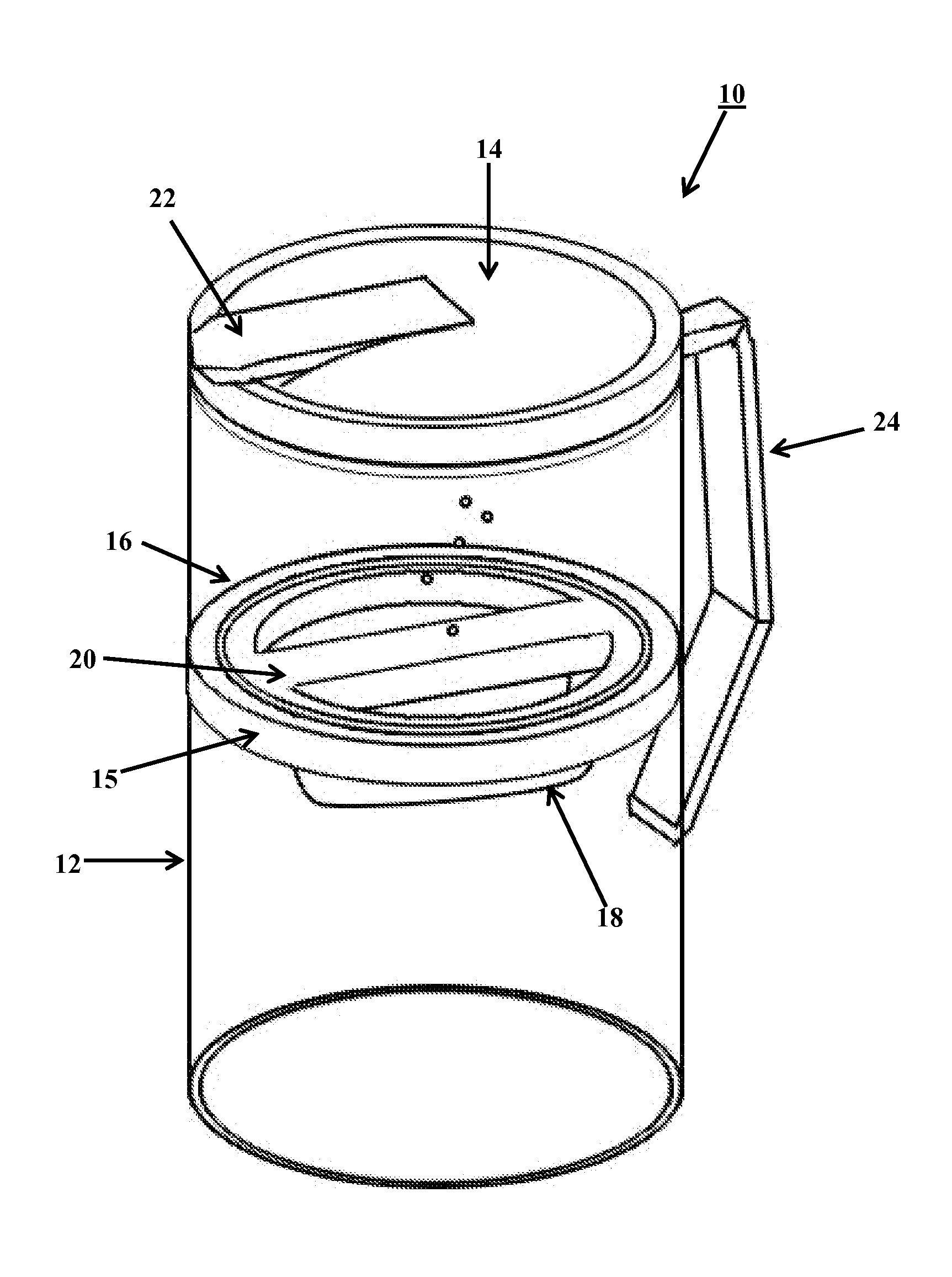

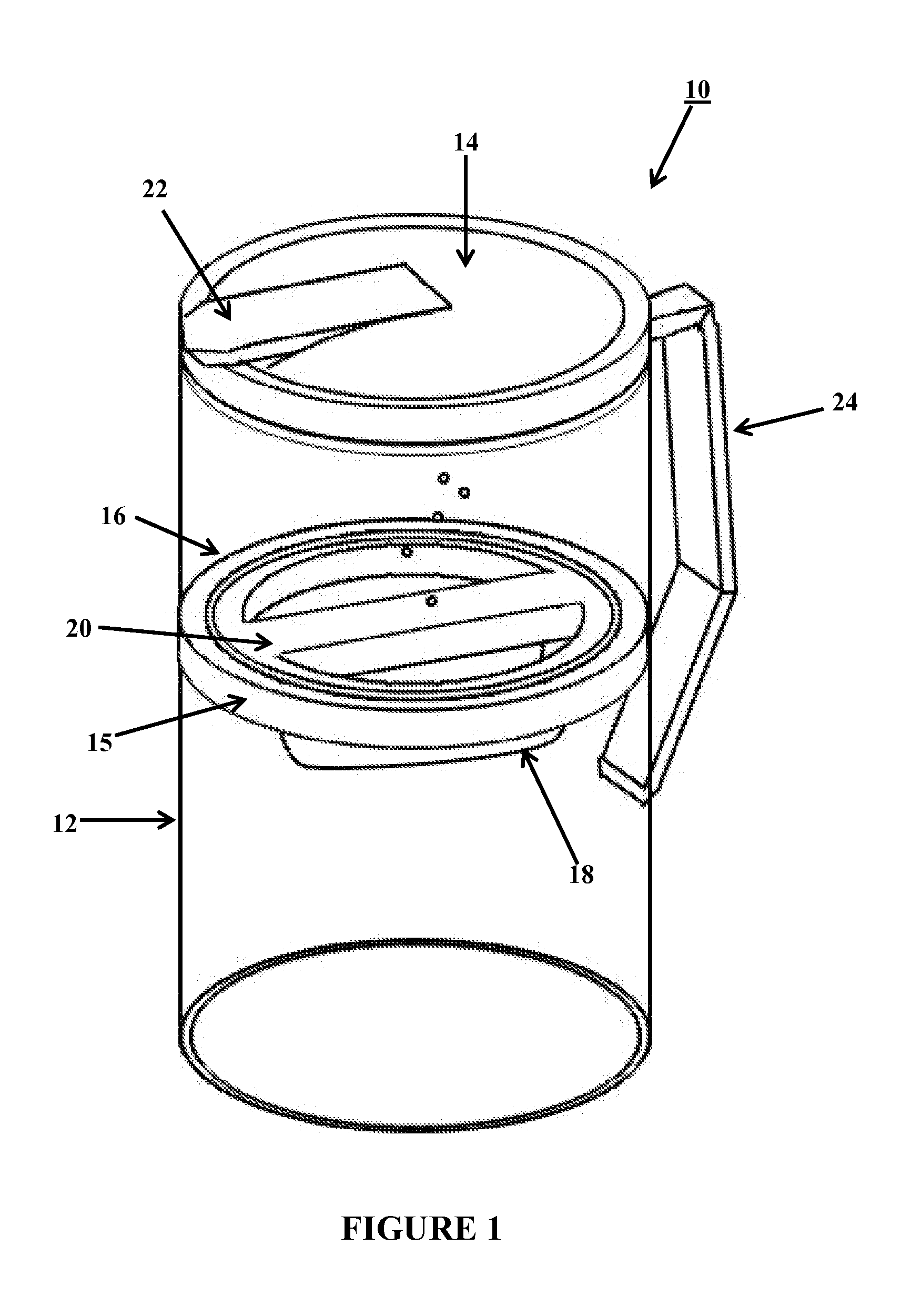

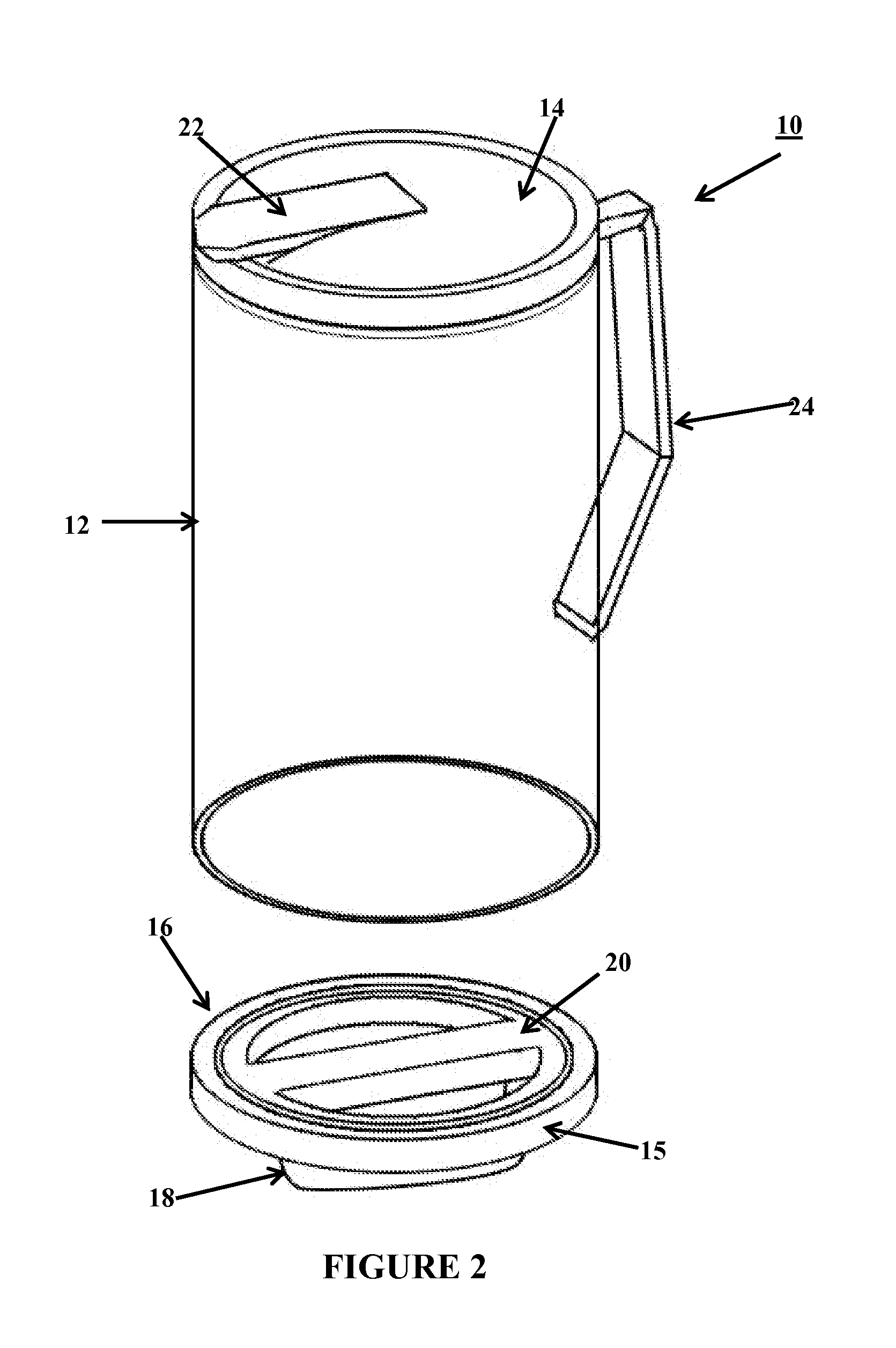

[0014]Referring now to FIGS. 1 and 2, there is shown the liquid storage container 10 in accordance with the present invention. The liquid storage container 10 comprises a tubular sleeve 12 having a removable top lid portion 14 and a bottom plunger 16 housed within sleeve 12. The bottom plunger 16 is sized and shaped to facilitate manual movement of the plunger 16 either up or down within sleeve 12. More specifically, bottom plunger 16 utilizes an outer gasket 15 to engage the interior of sleeve 12 for providing a liquid tight arrangement while simultaneously allowing the bottom plunger 16 to telescopically move up or down within sleeve 12 in responses to applied forces, as will be more fully described below.

[0015]Turning once again to FIGS. 1 and 2, in one preferred embodiment the bottom plunger 16 further defines a handle or grip 18 sized to be grasped by a human hand for telescopically applying up or down forces for telescopically moving the bottom plunger 16 within sleeve 12. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com