Heat-exchanger module with improved heat exchange and compactness, use with liquid metal and gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061]Other advantages and features of the invention will emerge more clearly on reading the detailed description of embodiments of the invention given by way of nonlimiting illustration with reference to the following figures, in which:

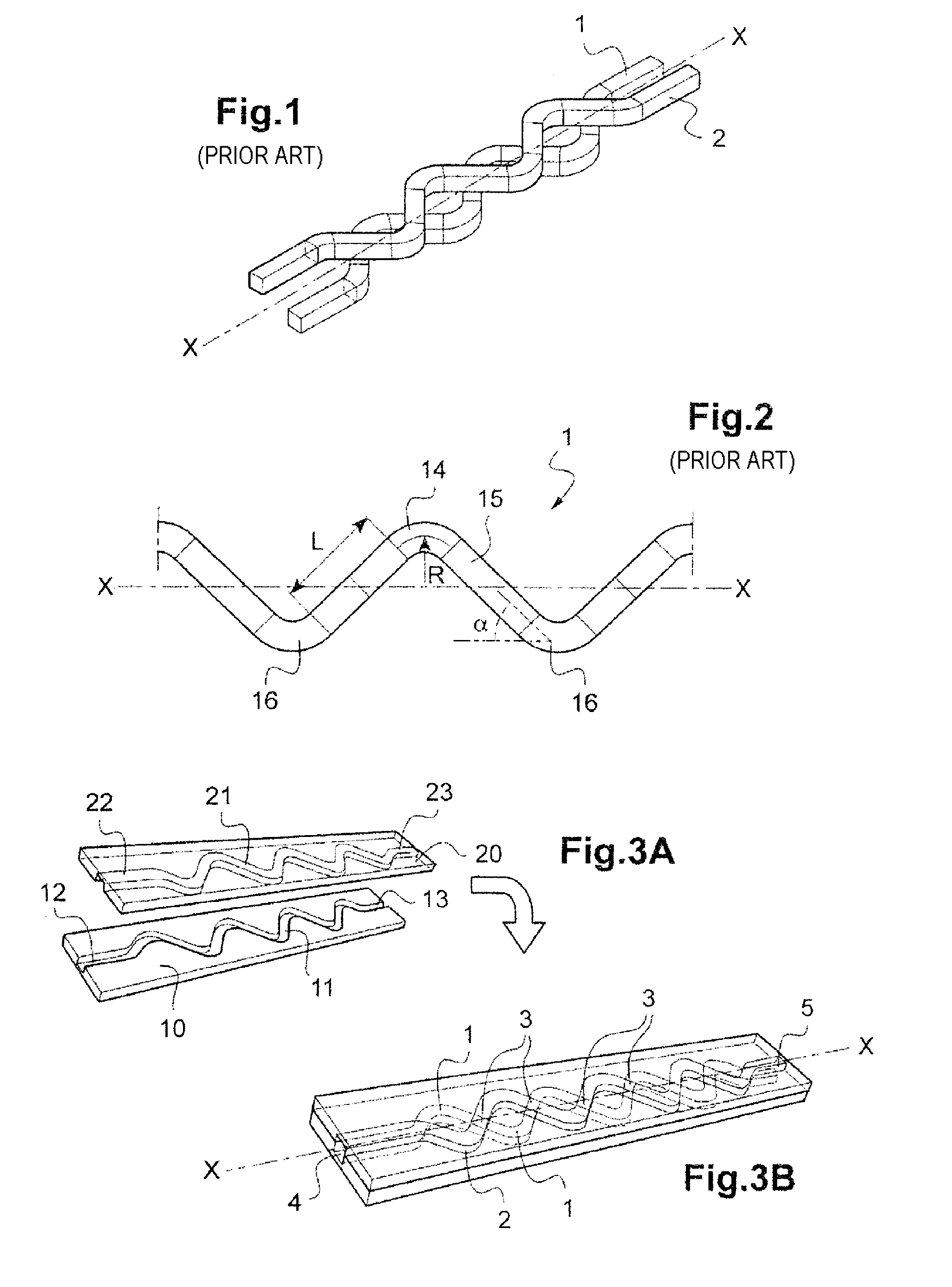

[0062]FIG. 1 is a perspective view of a prior art heat-exchanger module made from two plates;

[0063]FIG. 2 is a transparency detail view showing the zigzag profile of a channel of a heat-exchanger module according to FIG. 1;

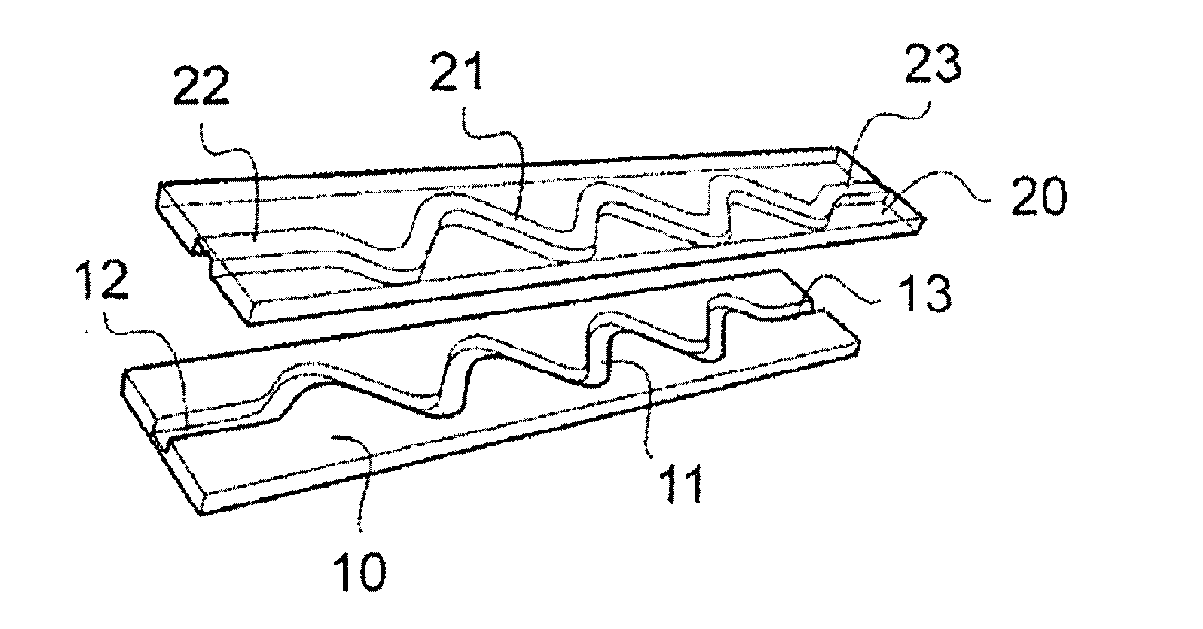

[0064]FIG. 3A is a perspective view of two plates with machined grooves before assembling them to constitute a heat-exchanger module according to the invention;

[0065]FIG. 3B is a perspective view of a heat-exchanger module according to the invention produced from the two plates according to FIG. 3A;

[0066]FIG. 4 is a transparency detail view showing the crossing areas between channels of a heat-exchanger module according to the invention;

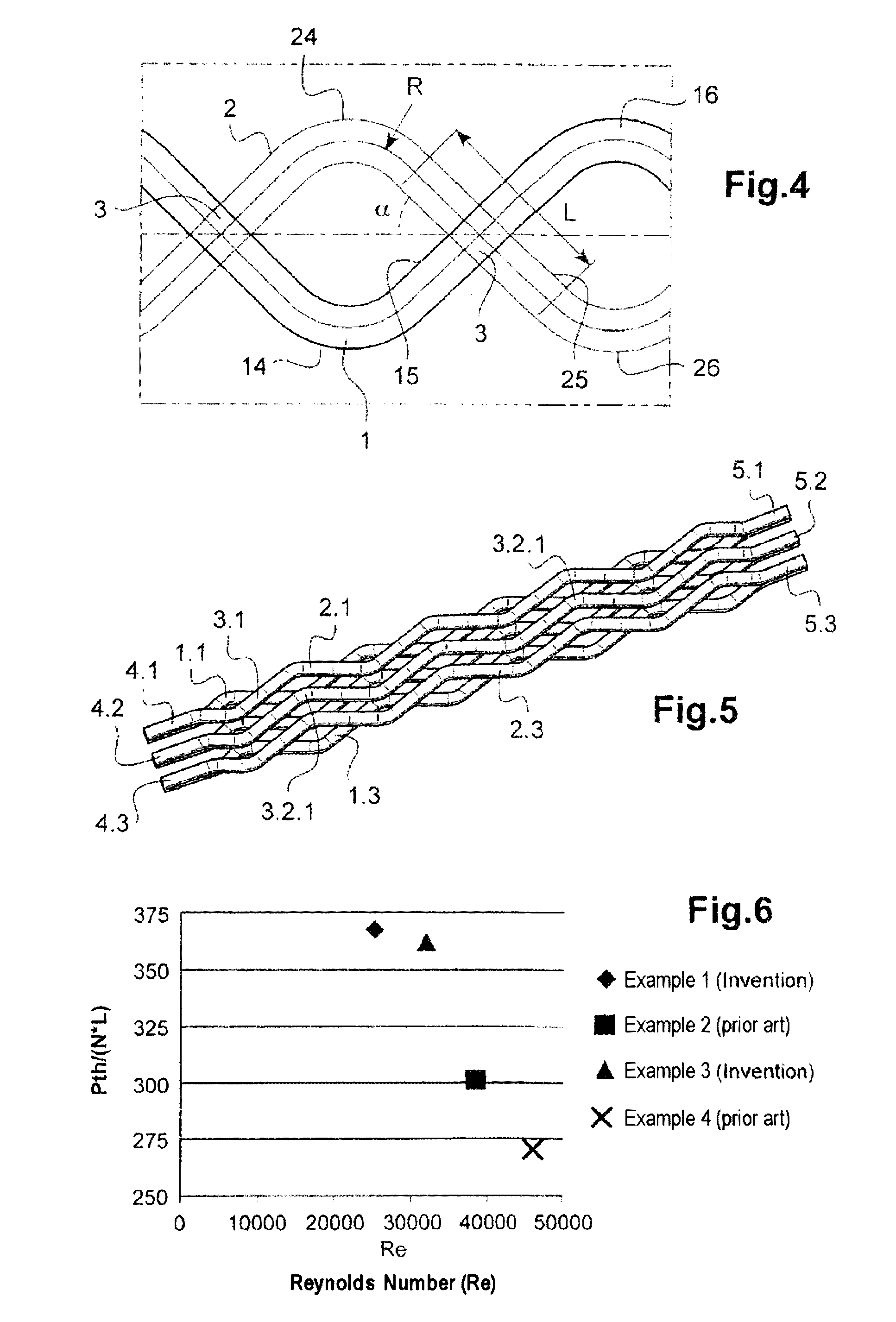

[0067]FIG. 5 is a perspective view of three pairs of channels in a heat-exchanger module accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com