Bent heat exchanger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033]Reference will be made in detail to embodiments of the present disclosure. The embodiments described herein with reference to drawings are explanatory, illustrative, and used to generally understand the present disclosure. The embodiments shall not be construed to limit the present disclosure.

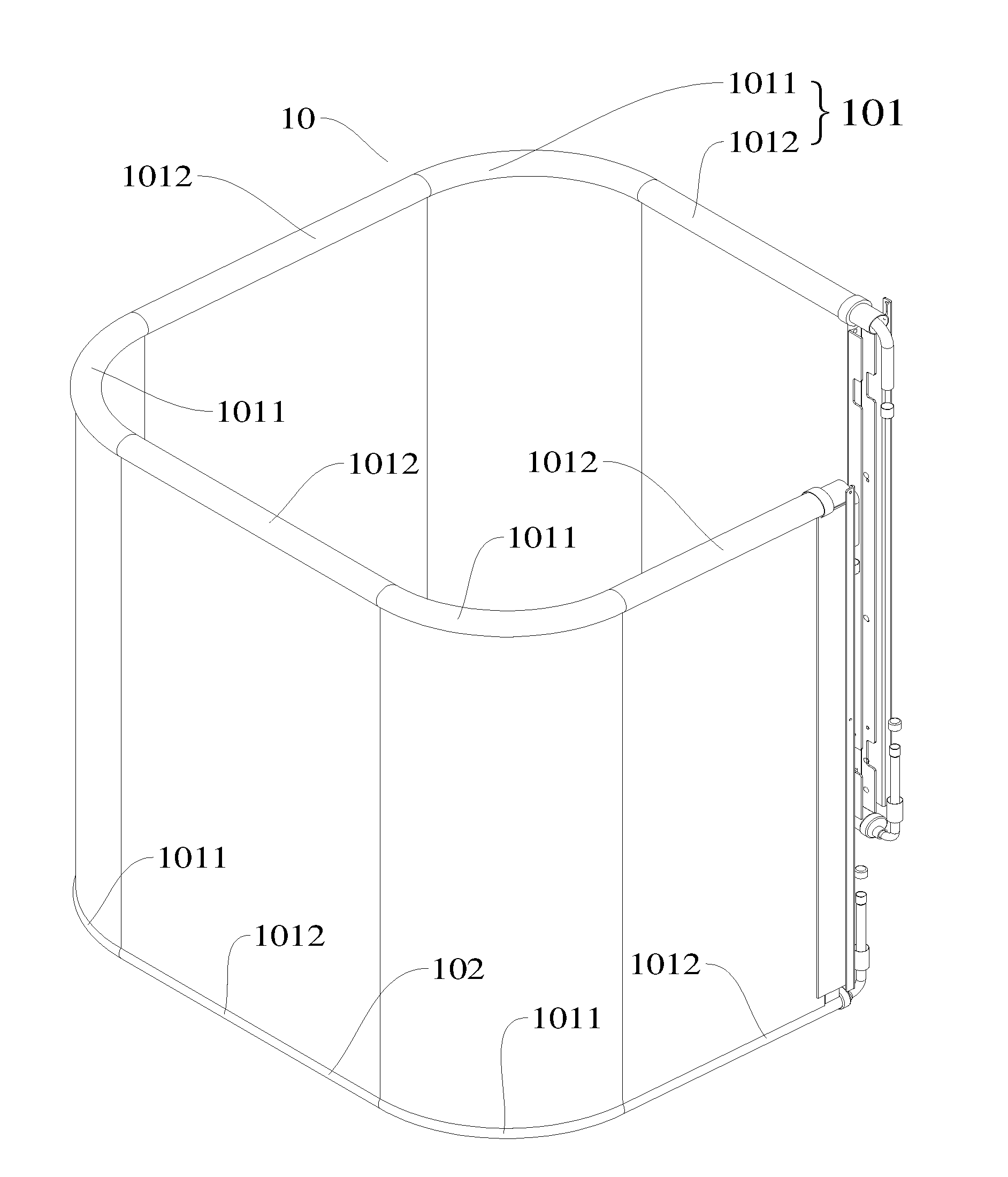

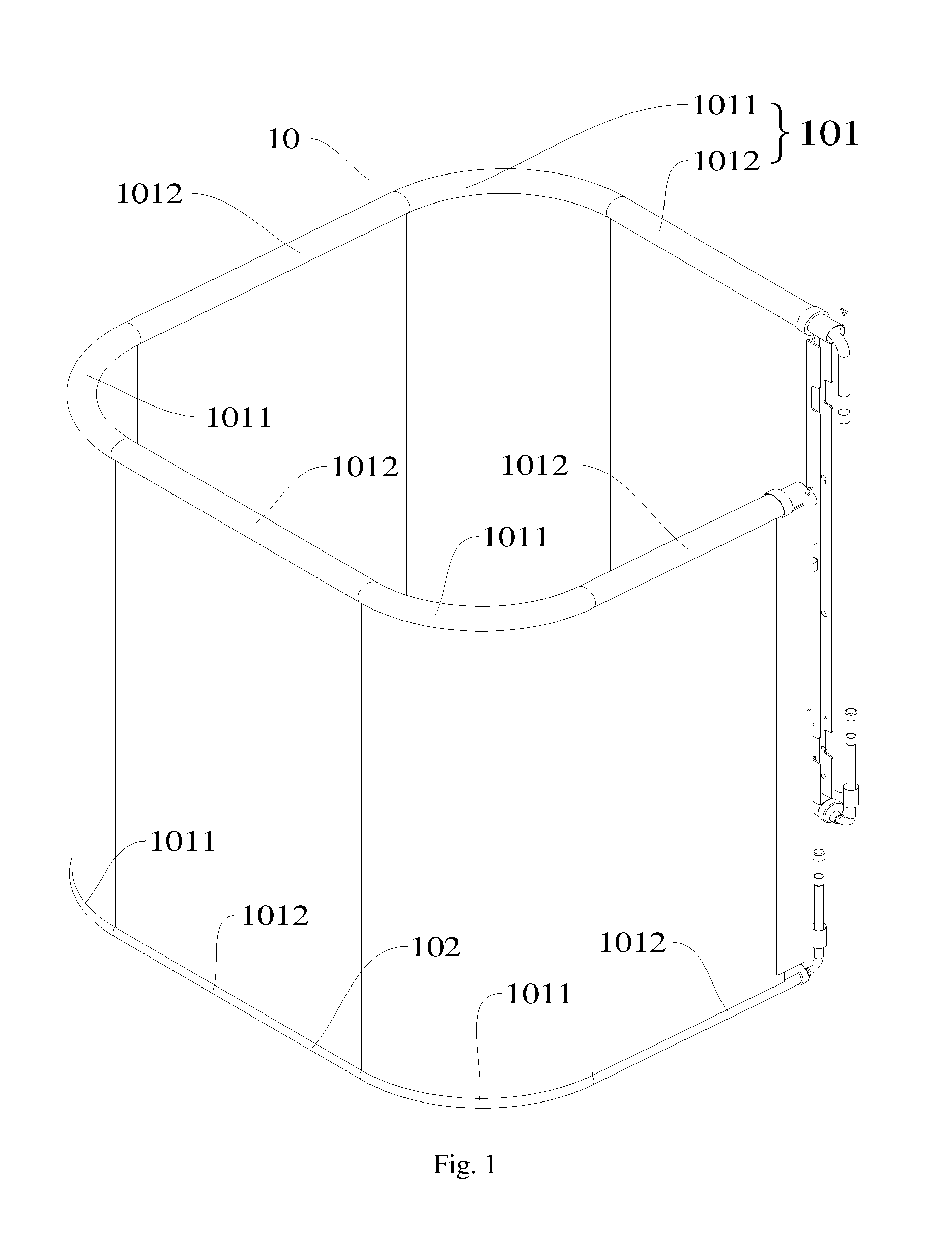

[0034]A bent heat exchanger 10 according to embodiments of the present disclosure will be described with reference to FIGS. 1-5 in the following. As shown in FIGS. 1-5, the bent heat exchanger 10 according to embodiments of the present disclosure includes a first header 101, a second header 102, fins 104 and a plurality of flat tubes 103.

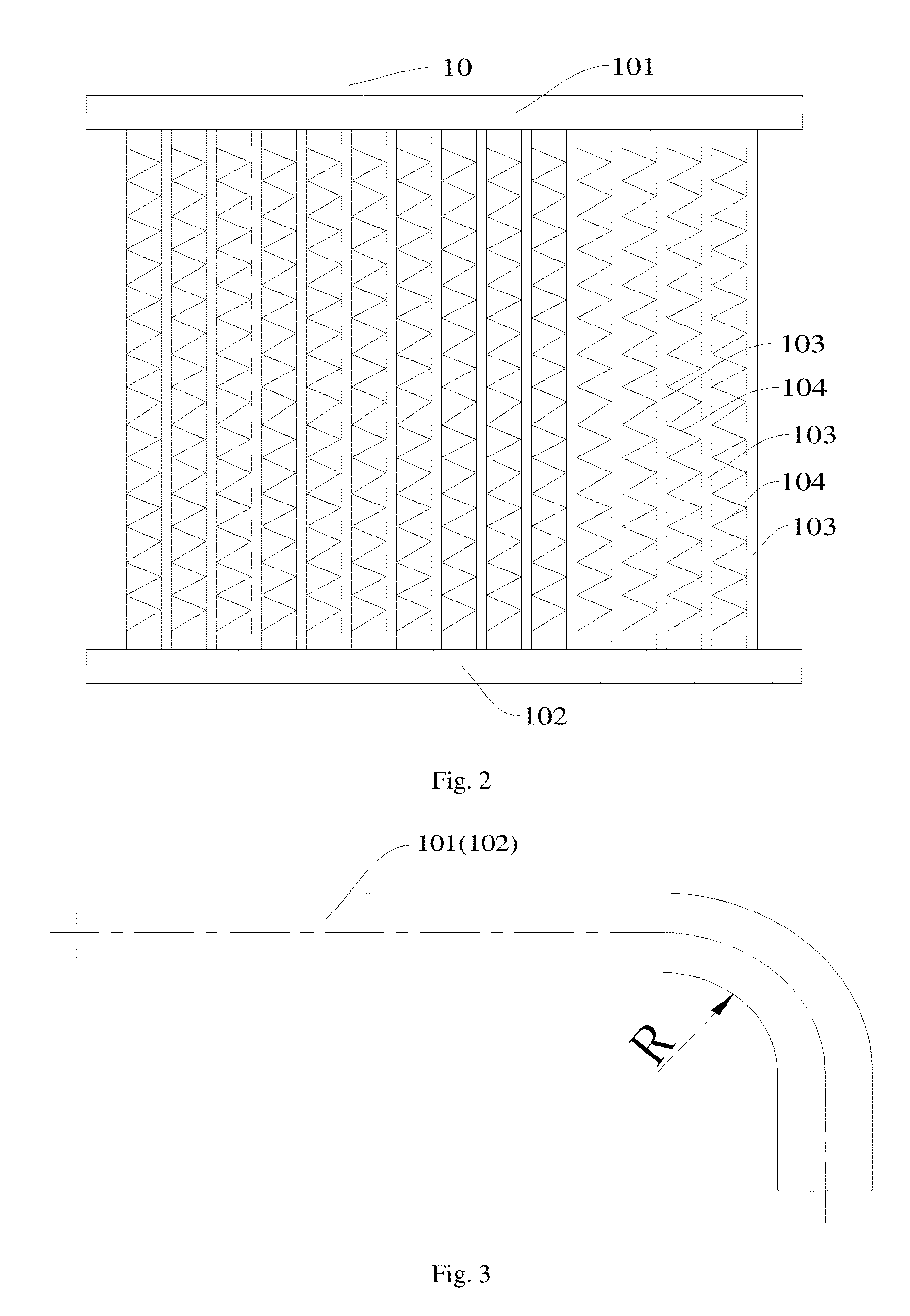

[0035]Each of the first header 101 and the second header 102 includes at least one bent segment 1011 and a straight segment 1012 adjoining the bent segment 1011. The bent segment 1011 of the first header 101 is corresponding to the bent segment 1011 of the second header 102. Two ends of the flat tube 103 are connected to the first header 101 and the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com