Modular temperature controlled shipping container

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

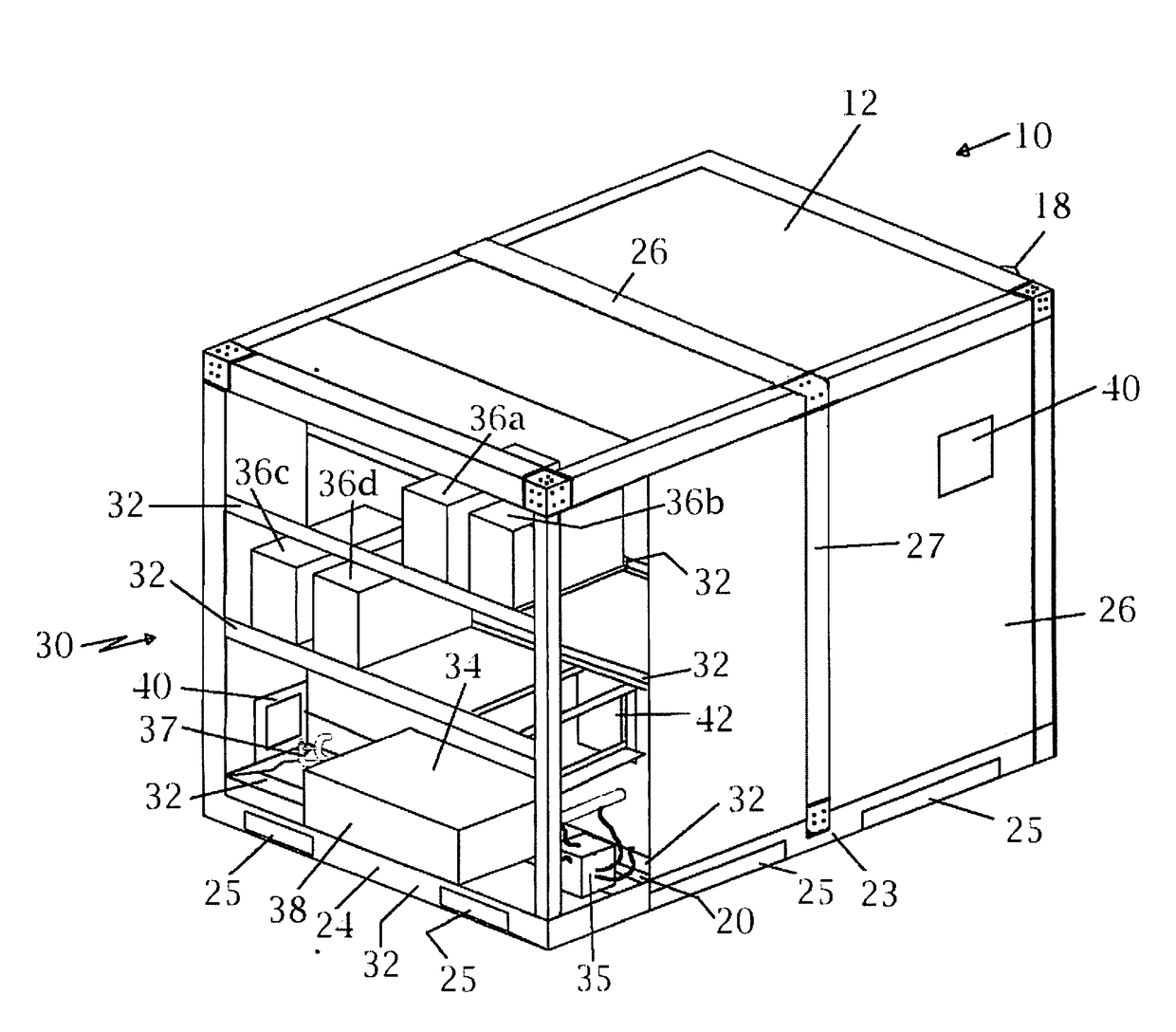

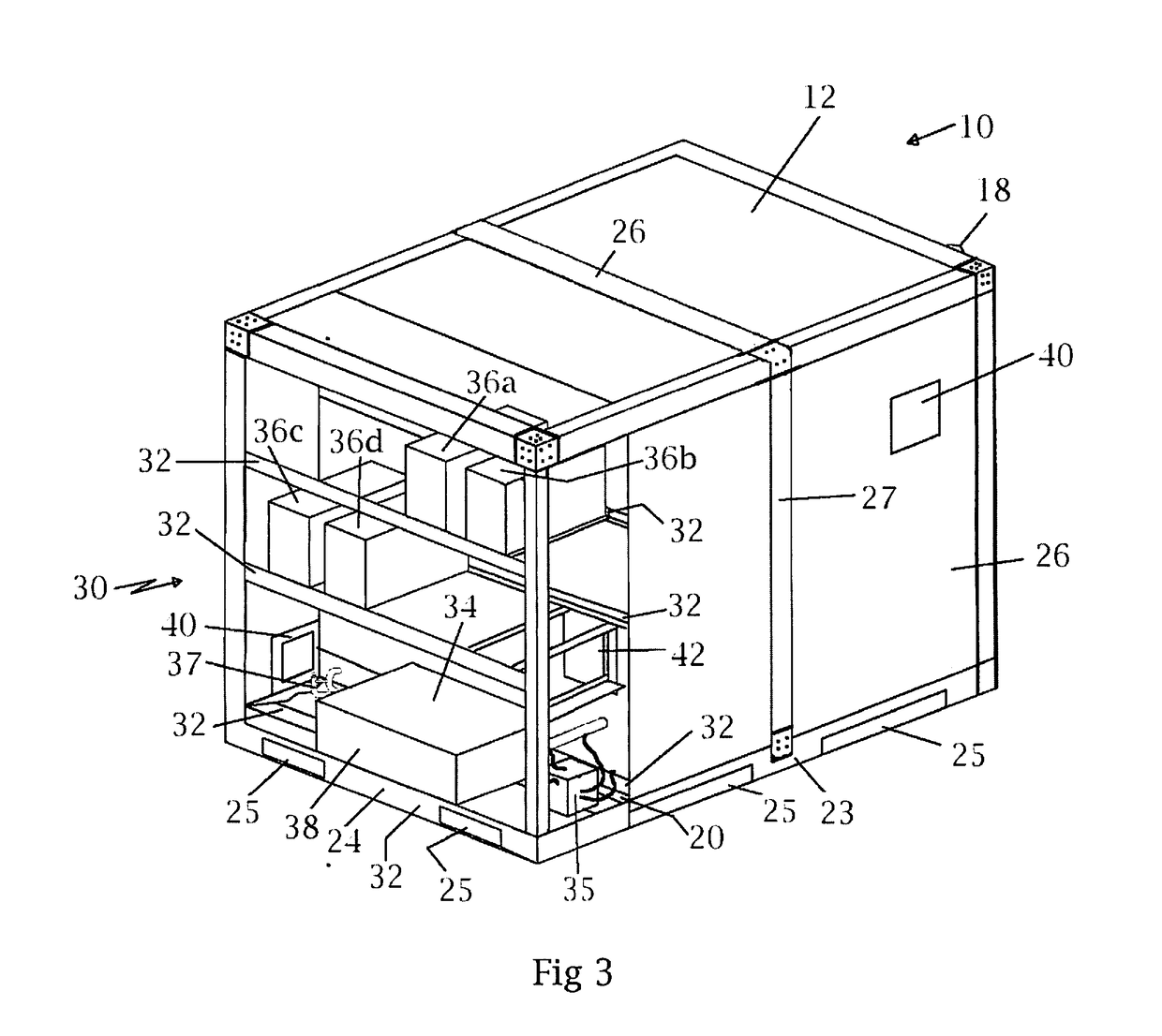

[0039]As shown in FIG. 1, the container 10 of the subject invention is a box having sidewalls 11 (and an opposite wall 26, see FIG. 3) a top 12 and a bottom structure 13. The front end 14 includes and access door 16 mounted on hinges 17 and including a locking and latching system 18. As will be further described herein the back end 19 of the box includes an accessible chamber housing the on-board power supply, heating and cooling system and sealed sump. As shown in FIGS. 1 and 3, the bottom structure 13 includes a raised floor, mounted on or near the top of the bottom rails 21, 22, 23 and 24. This permits a forklift or similar machine to lift and move the box by inserting the forks into the rail slots 25 provided in the rails 21-24. Where desired, reinforcing bands 26 may be mounted on the outer structure for increasing the strength and rigidity of the box.

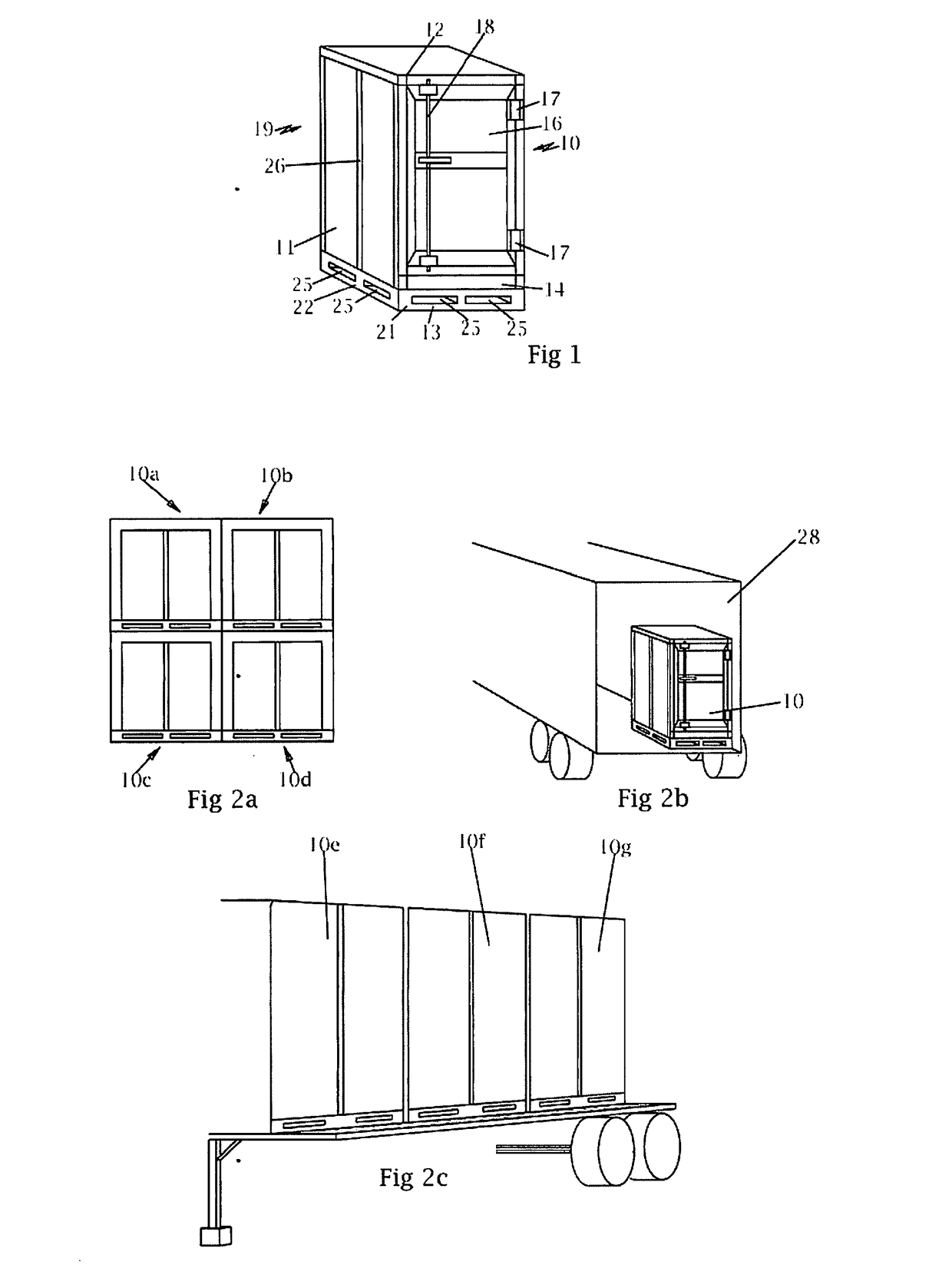

[0040]FIGS. 2a, 2b and 2c are illustrations of exemplary, but not exhaustive, configurations for stacking, loading and preparing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com