Heat and mass exchange module and use thereof

a heat and mass exchange module and heat exchange technology, which is applied in the direction of stationary conduit assemblies, heating types, stationary plate conduit assemblies, etc., can solve the problems of increasing particularly liquid desiccant, damaging pipes and other materials in an unpredictable and undetectable manner, and the integration of a module into an air-conditioning system, so as to effectively set the linear speed of liquid flow, reduce the risk of liquid carrying over, and reduce the effect of surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

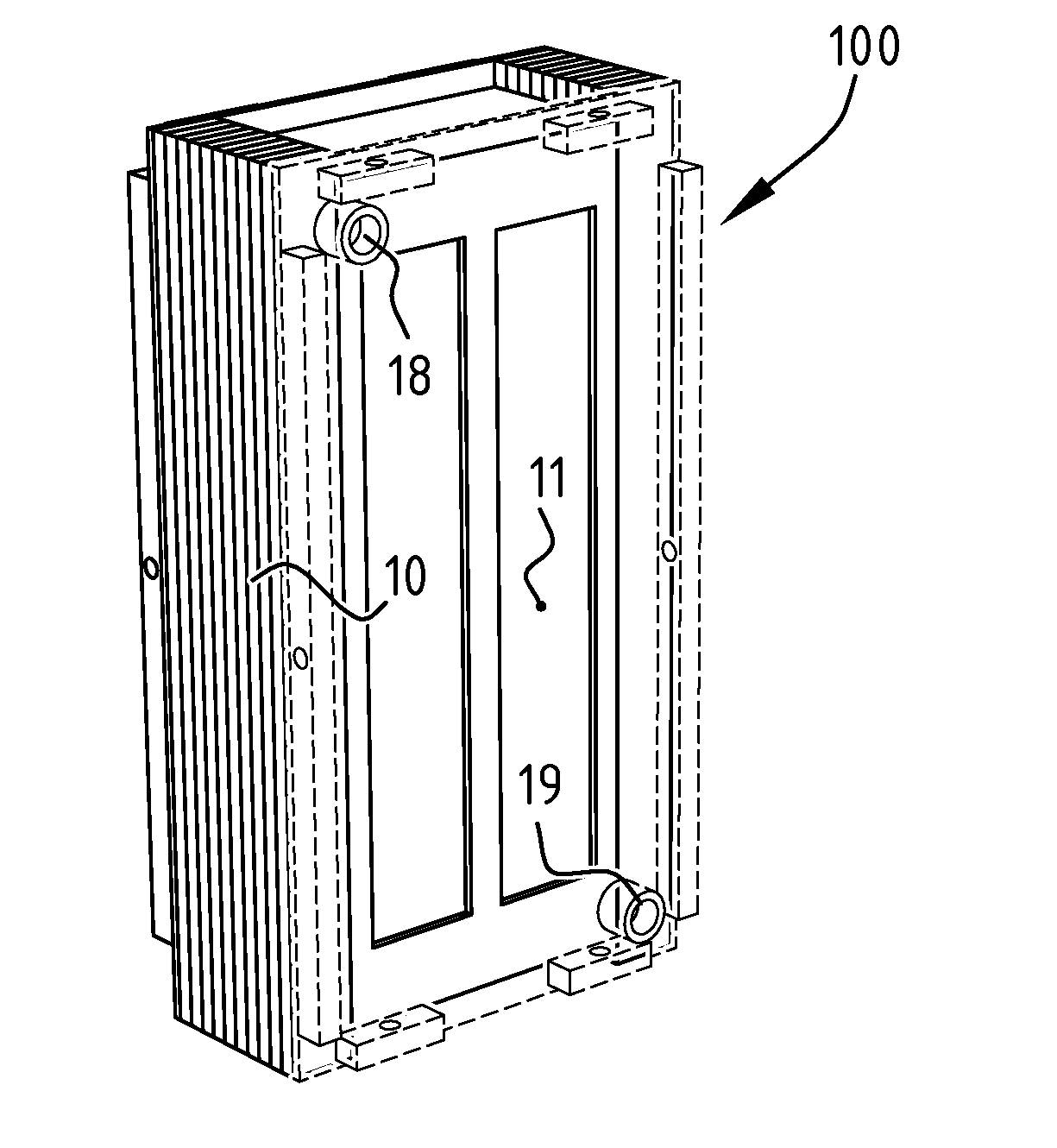

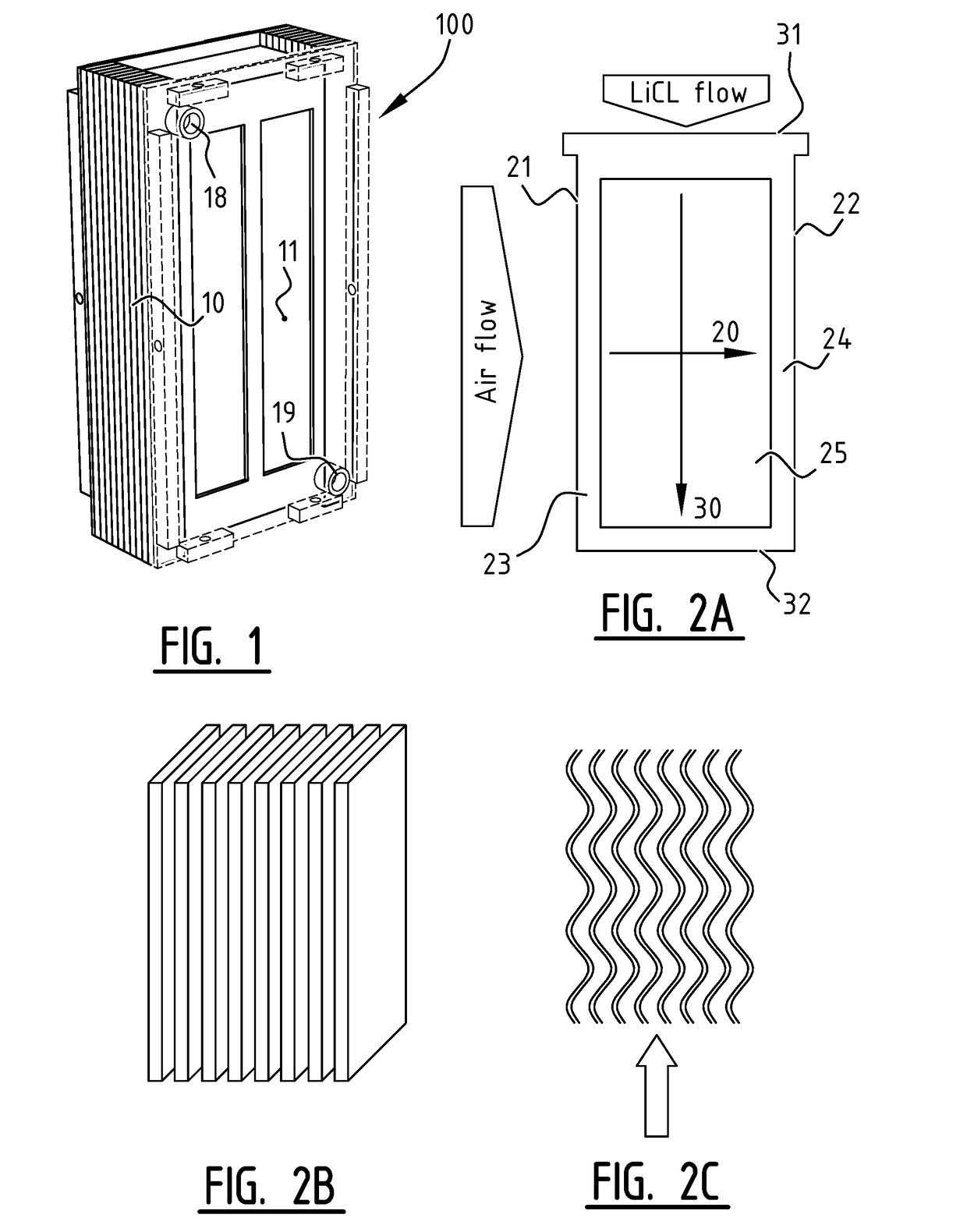

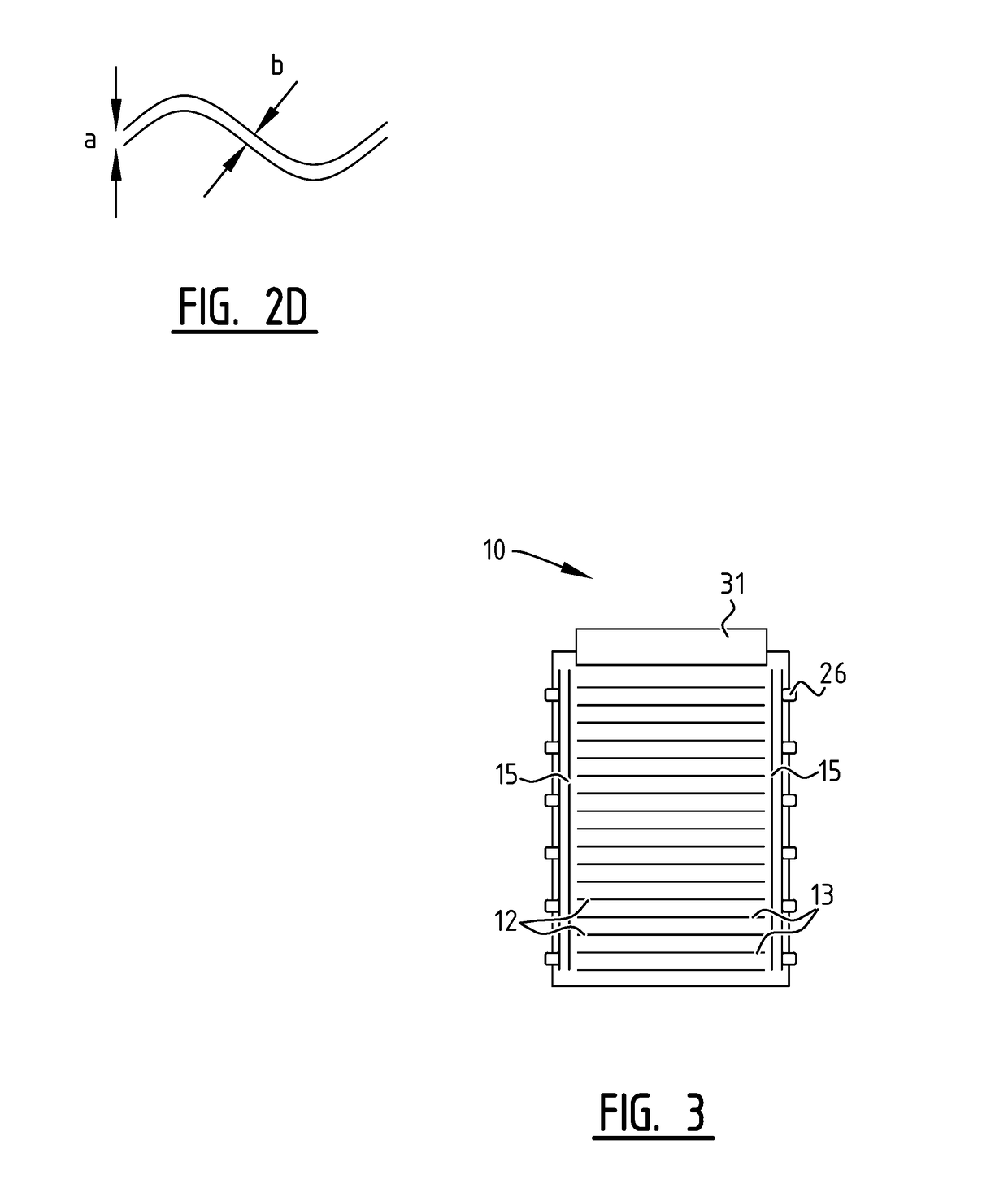

[0048]FIG. 1 shows in a diagrammatical view an HMX module 100 according to a first embodiment of the invention. The HMX module 100 comprises a plurality of plates. Most preferably, the plates are sheets 10, which comprise a carrier layer between a first and a second layer of wicking material. The wicking material is more suitably a non-woven textile material, such as cotton or rayon. The first and second layer may further contain another material mixed therewith, such as an engineering plastic. More details on the sheet are specified in the non-prepublished application NL2013566 in the name of Applicant. However, alternative options are not excluded in the context of the present invention. The sheets are suitably substantially identical, so that the corrugation in the sheets is repetitive and the distance between the sheets does not change. The sheets are corrugated, as will be discussed with reference to following figures. Due to the corrugation and its orientation, the sheets, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com