Structural element with anticipated prestressing

a structural element and prefabricated technology, applied in the direction of structural elements, building components, floors, etc., can solve the problems of reducing the service life of the structure element, so as to reduce the risk of cracks and less bending. , the effect of less risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

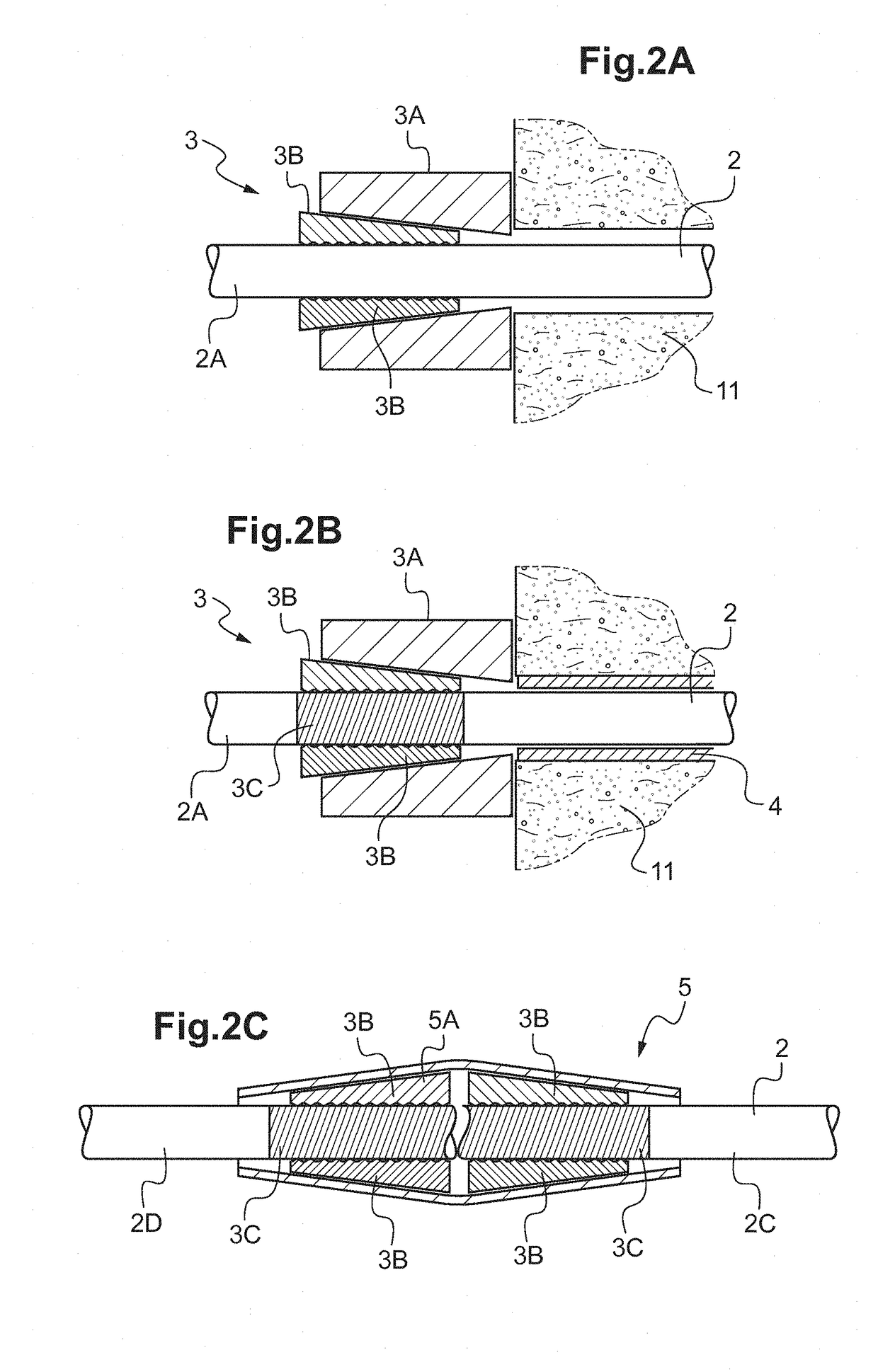

[0147]FIG. 3A shows a beam 20 of the invention.

[0148]In this embodiment, the body 21 of the beam 20 presents a cross-section that is I-shaped.

[0149]As shown in FIG. 3B, the body 21 of the beam 20 thus presents two parallel flanges 23 between which a vertical web 22 extends.

[0150]The first and second tensioners 1, 2 thus extend over the entire length of the beam 20, parallel to one another.

[0151]In this embodiment, five first tensioners 1 are provided, embedded in the concrete of the bottom flange 23 of the body 21 of the beam 20. In this embodiment, the first tensioners 1 are once more regularly distributed over the width of the beam 20. Thus, when they compress the body 21 of the beam 10, they do not deform it in twisting.

[0152]The five first tensioners 1 are situated in the proximity of the bottom face of the bottom flange 23. Thus, when they are tensioned, they make it possible to bend the body 21 of the beam 20 so that the center of the beam moves upwards.

[0153]Three second tens...

first embodiment

[0154]FIGS. 4A and 4B show a slab 30 of the invention.

[0155]In this embodiment, the body 31 of the slab 30 presents the general shape of a rectangular parallelepiped. Its neutral axis A1 thus coincides with the central longitudinal axis of the body 31.

[0156]In this embodiment, the ends of the slab 30 nevertheless present respective rims 32 projecting from the top face of the body 31. The two rims 32 run along the two ends of the body 31. They co-operate with each other to define a cavity 33 between them into which a screed could be poured.

[0157]The first and second tensioners 1, 2 extend over the entire length of the slab 30, parallel to one another.

[0158]In this embodiment, a plurality of first tensioners 1 are provided, embedded in the concrete of the body 31 of the slab 30. In this embodiment, the first tensioners 1 are once more regularly distributed over the width of the slab 30, below the neutral axis A1. They are situated in the proximity of the bottom face of the body 31 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com