Bottling system

a technology of container and bottle, applied in the field of container system, can solve the problems of inconvenient and normal processing time, and achieve the effect of cost-effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

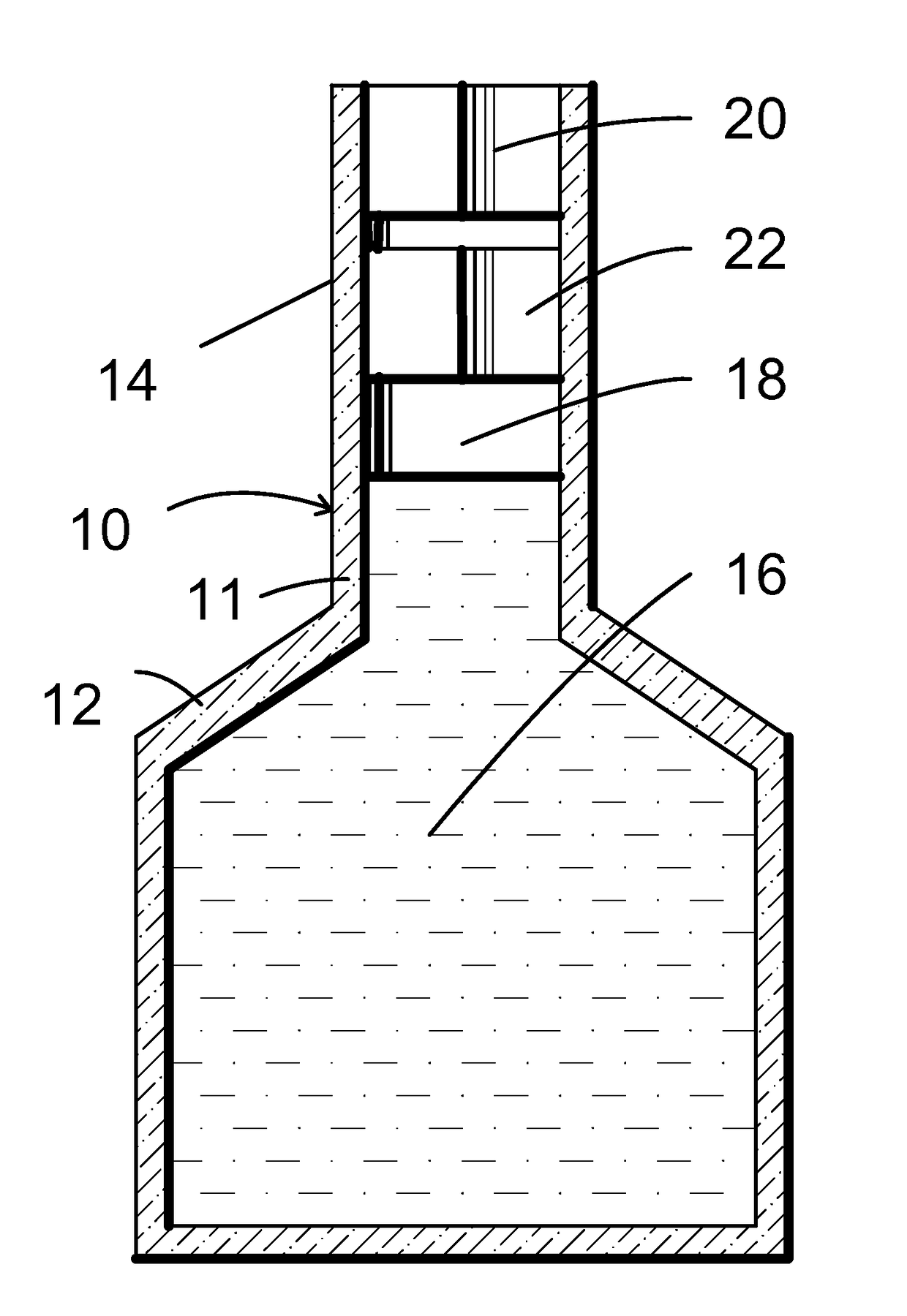

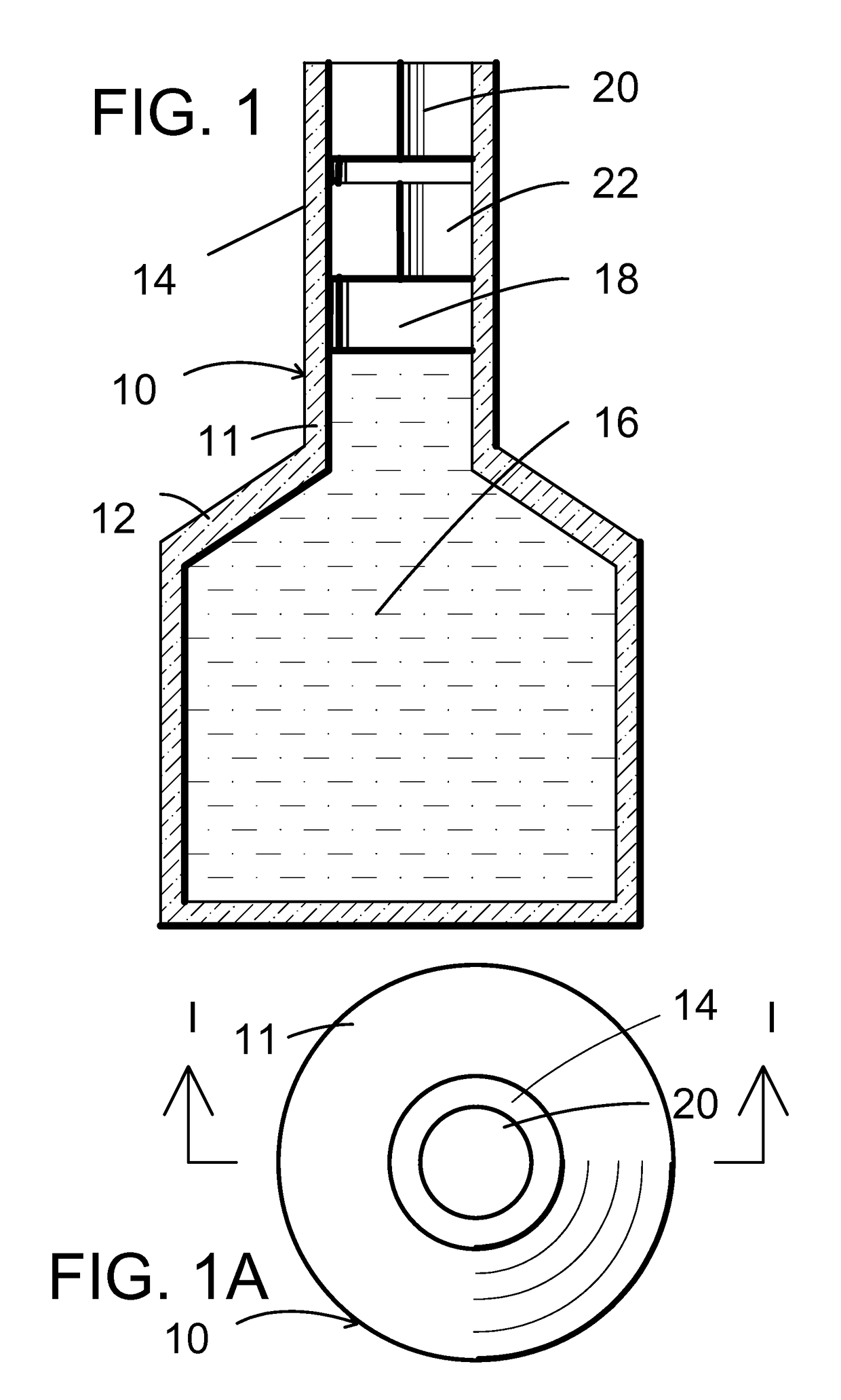

[0034]Referring first to FIG. 1, FIG. 1 is a sectional front elevation view, taken along view 1-1 of FIG. 1A, of a container system for liquids, showing the location of the in-container mixer / aerator in the exit throat of the container. The bottling system, denoted generally by the numeral 10, includes a bottle 11, that includes a hollow body 12 and a neck 14. The body 12 contains a liquid 16, such as wine. The neck 14 surrounds a hollow bore 18 that allows the liquid 16 to exit the bottle 11.

[0035]At the outboard end of the bore 18, is a cork 20 that is removable to allow the liquid 16 to be poured from the bottle 11.

[0036]Inward of the cork is a mixer 22, that includes axial channels 24 that allow liquid to turbulently exit the bore 18, and air to enter the bore 18. The turbulent exit of the liquid 16 enhances the “breathing” of the exiting liquid 16.

[0037]FIG. 1A is a plan view of a container system for liquids shown in FIG. 1.

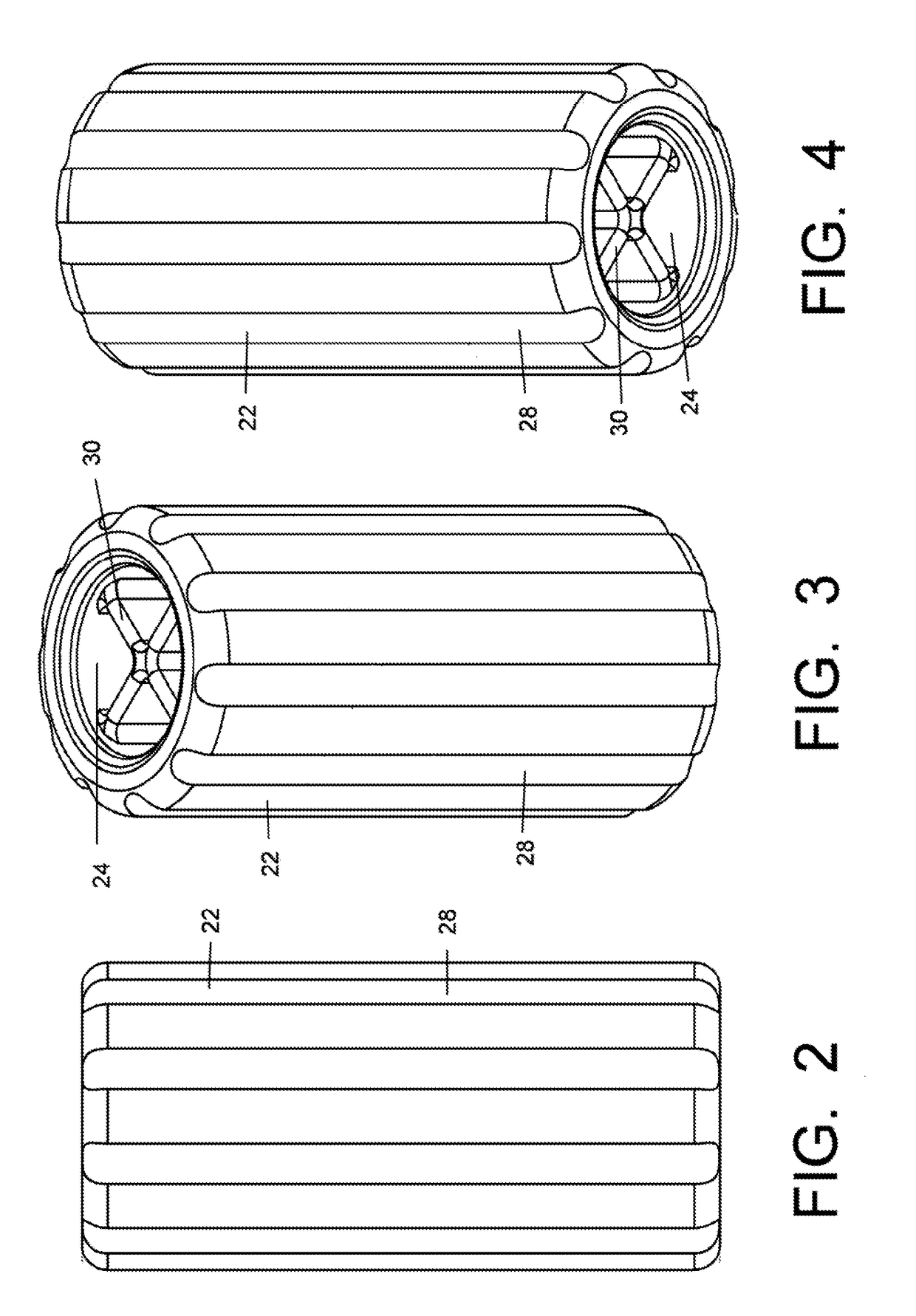

[0038]FIG. 2 is a front elevation view of a mixer emb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

| perimeter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com