Pneumatic Trench Compaction Wheel Attachment for an Excavator

a technology of pneumatic wheel and excavating machine, which is applied in the field of pneumatic wheel attachment for excavators, can solve the problems of wet and sticky soils, high cost of vibratory plate compactors, and clogging of pad-foot type steel compaction wheels,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009]All illustrations of the drawings are for the purpose of describing selected versions of the present invention and are not intended to limit the scope of the present invention.

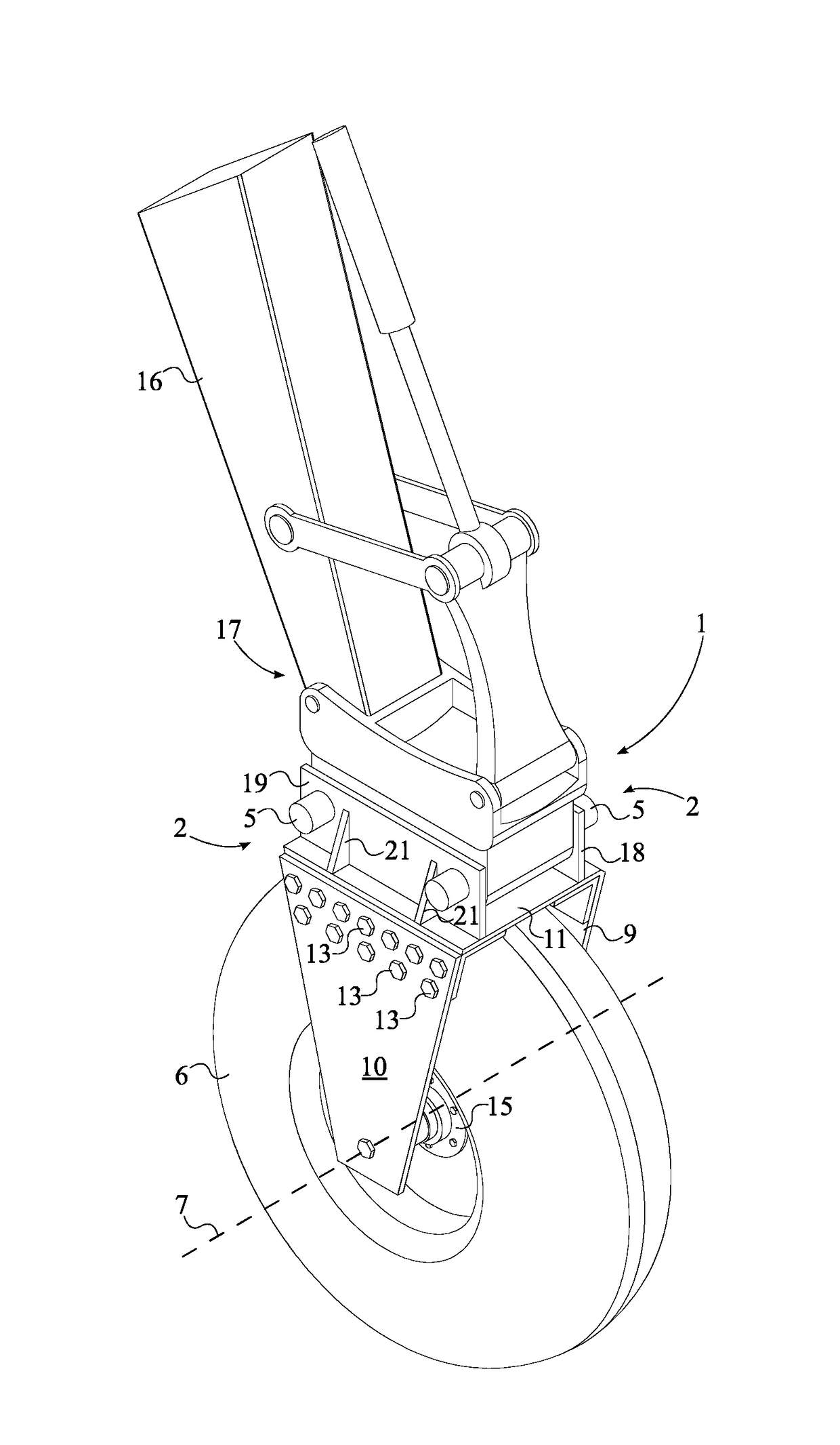

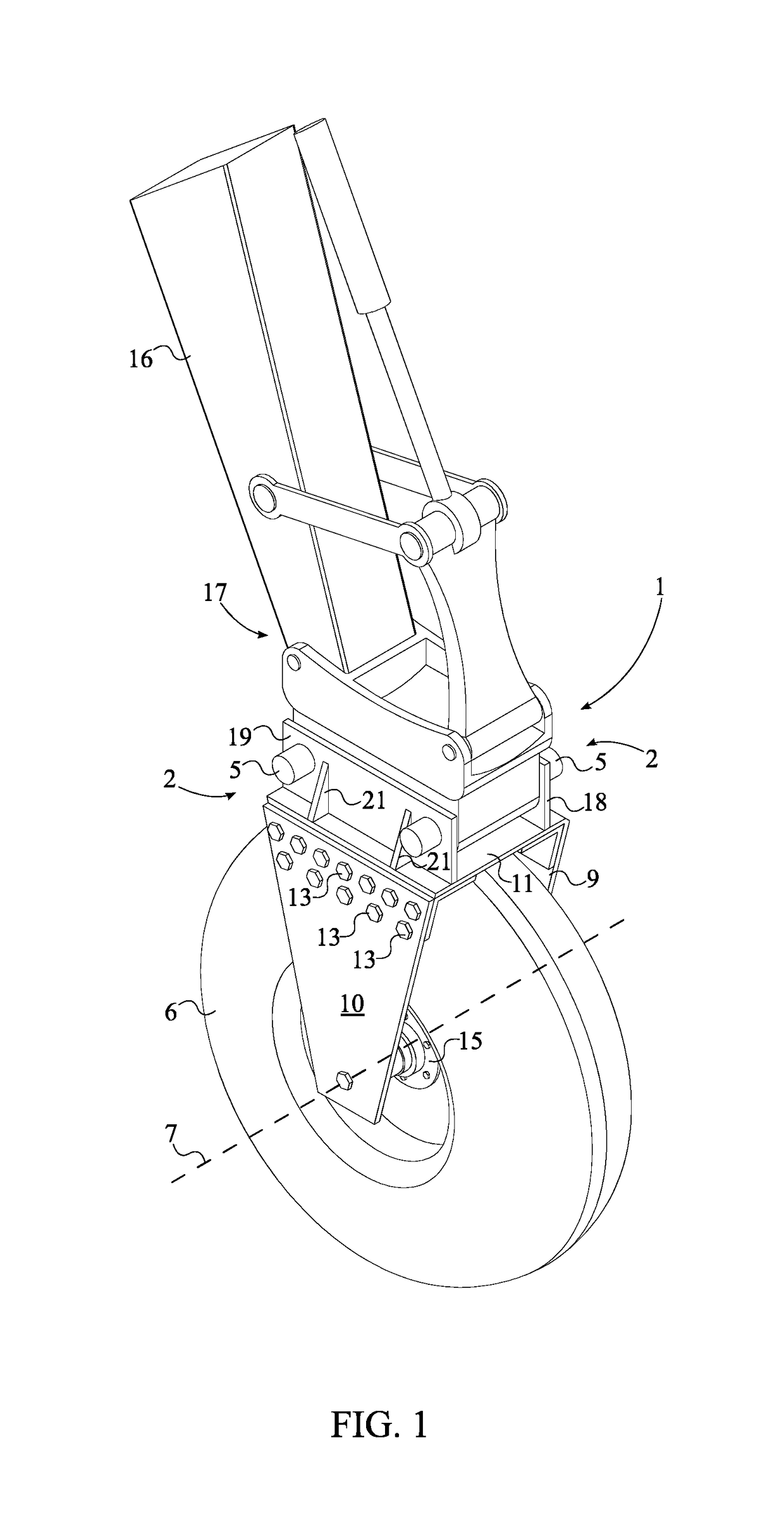

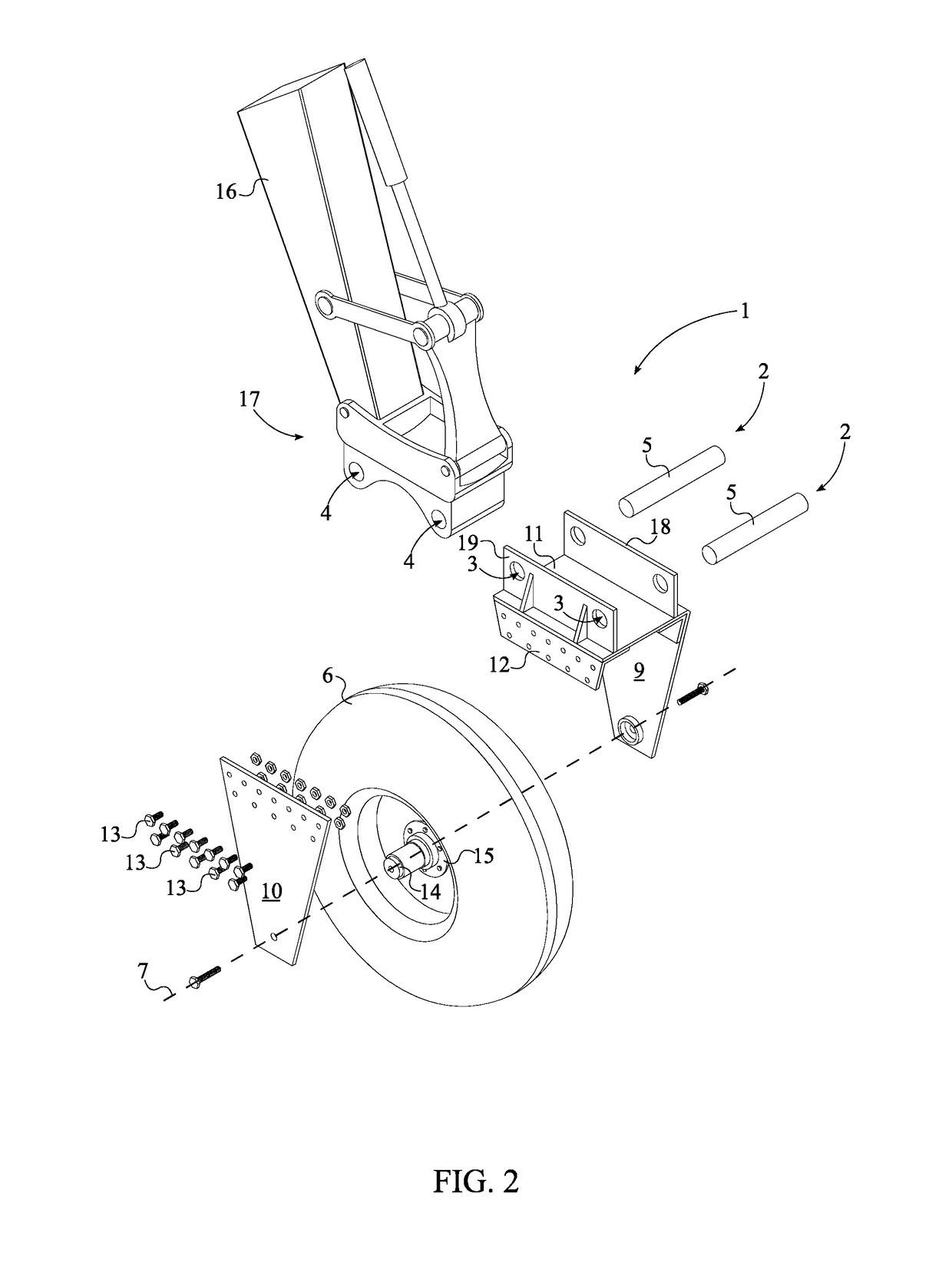

[0010]The present invention generally relates to trench compaction mechanisms. More specifically, the present invention is a pneumatic wheel attachment for an excavator boom 16. The present invention provides a more efficient means for trench compaction when compared to traditional means such as vibratory plates and pad-foot steel compaction wheels.

[0011]Referring to FIG. 1, the present invention comprises a pneumatic compaction wheel 6, a wheel yoke 8, and a boom mounting assembly 1. The pneumatic compaction wheel 6 is a relatively large pneumatic wheel with a preferred width nearly equal to the width of the trench to be backfilled. The pneumatic compaction wheel 6 has a relatively large diameter that creates a smooth rolling compaction with a large foot print. The large foot print allows the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com