Hydraulic connection-board pile board and method for reinforcing it and forming large feet pile

A technology of hydraulic inserting plate and pile plate, which is applied in the direction of sheet pile wall, building, foundation structure engineering, etc., can solve the problems that it is difficult to meet the needs of the project, the volume of the sediment space increases, and the speed is slow, so as to improve the bearing capacity, The effect of reducing material consumption and increasing bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

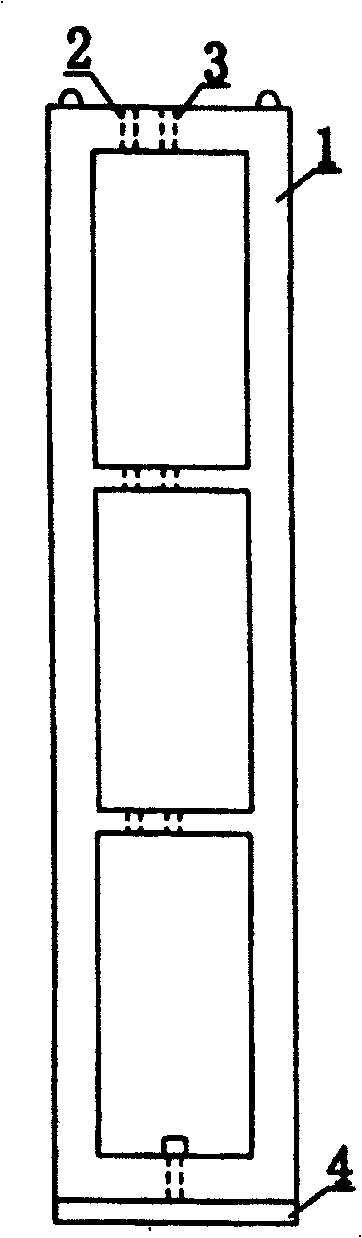

[0028] see Figure 1-Figure 17 , a method for strengthening hydraulically inserted pile slabs and construction method of big foot piles, the hydraulically inserted pile slabs include frame slabs and trough shaped slabs and hydraulic distribution pipes installed at their lower ends, the frame slabs or trough shaped slabs are vertically arranged with Install the through holes 2 and 3 of the Gaza conduit and the water pipe.

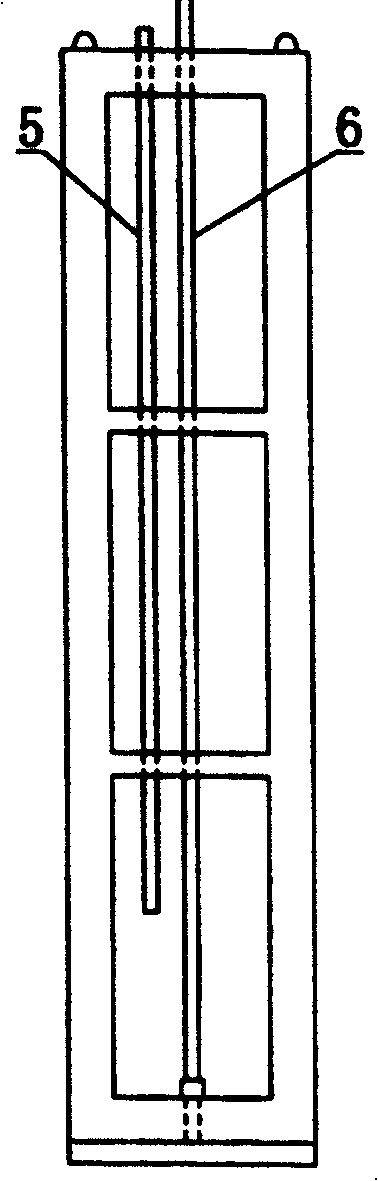

[0029] The hydraulic inserting pile slab can also be a combined structure comprising a start plate, a middle plate and an end plate as a bridge pile or a wharf pile. The inside of the start plate and the end plate is provided with a slideway 9 or a slide plate 10, and the two sides of the middle plate A slideway 9 and a slide plate 10 are respectively provided, and the start plate, the middle plate and the end plate are all provided with hydraulic distribution pipes and through holes 2, 3 for installing the water pipe and the Gaza conduit.

[0030] The rein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com