New bottle cap

a bottle cap and bottle body technology, applied in the field of new bottle caps, can solve the problems of affecting the experience of users, limiting the development of the industry, and difficult reuse for users, and achieve the effect of convenient and stable experience, simple and reasonable structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]Drawings and detailed embodiments are combined hereinafter to elaborate the technical principles of the present invention.

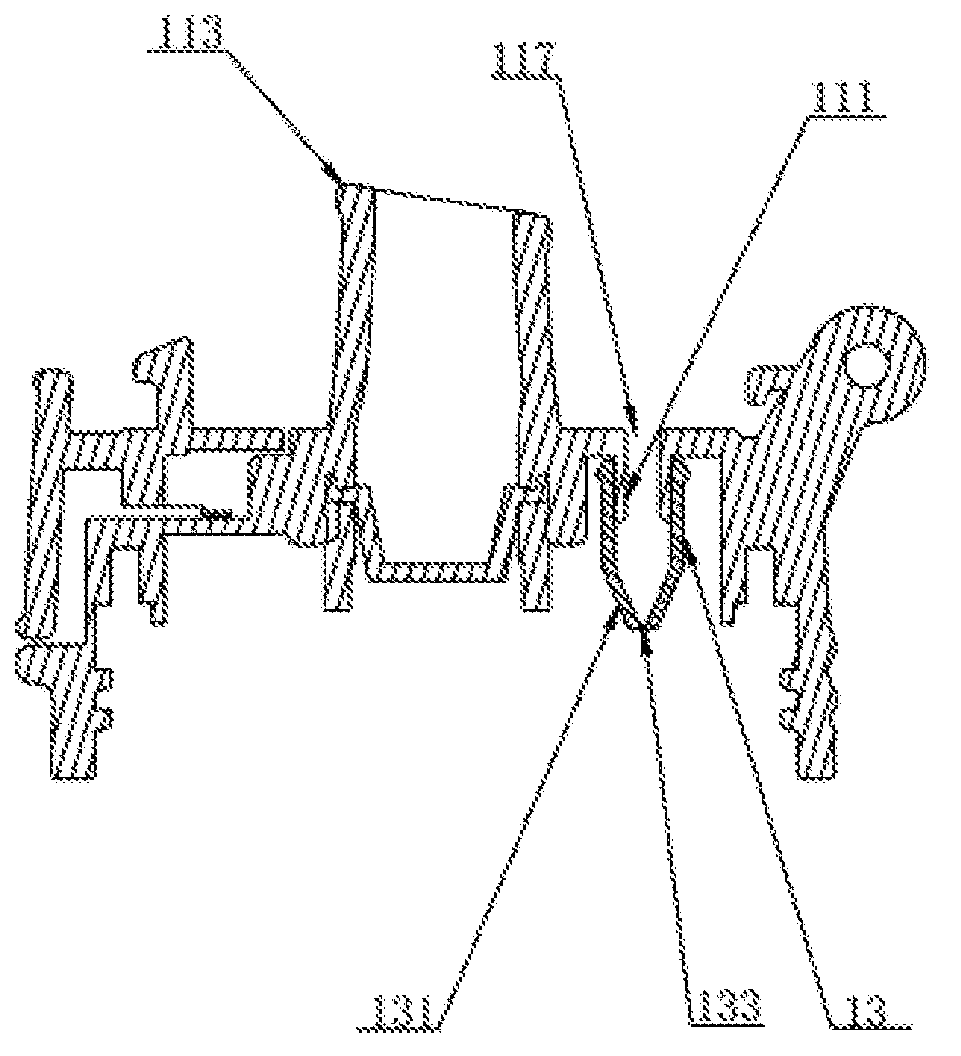

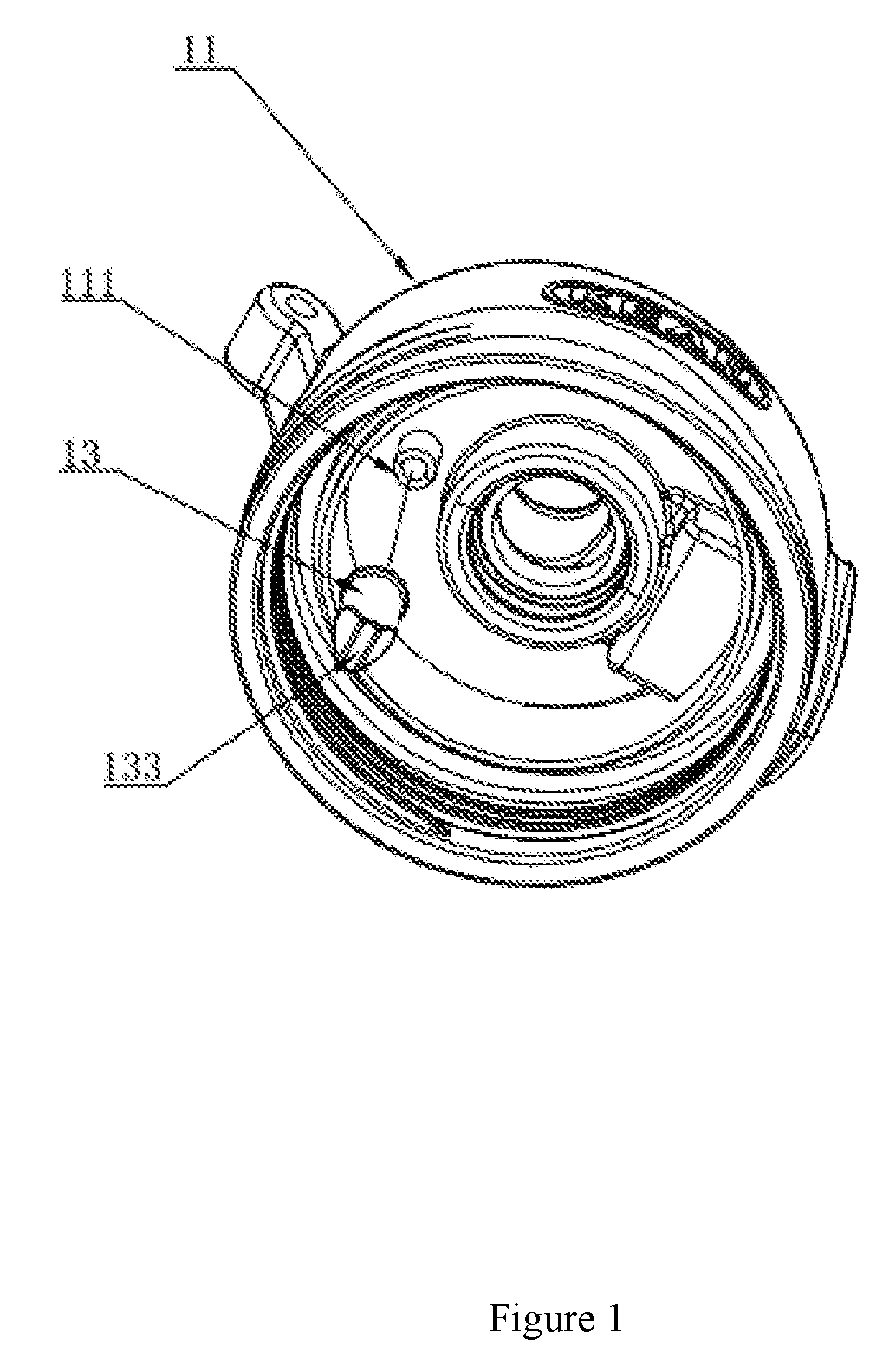

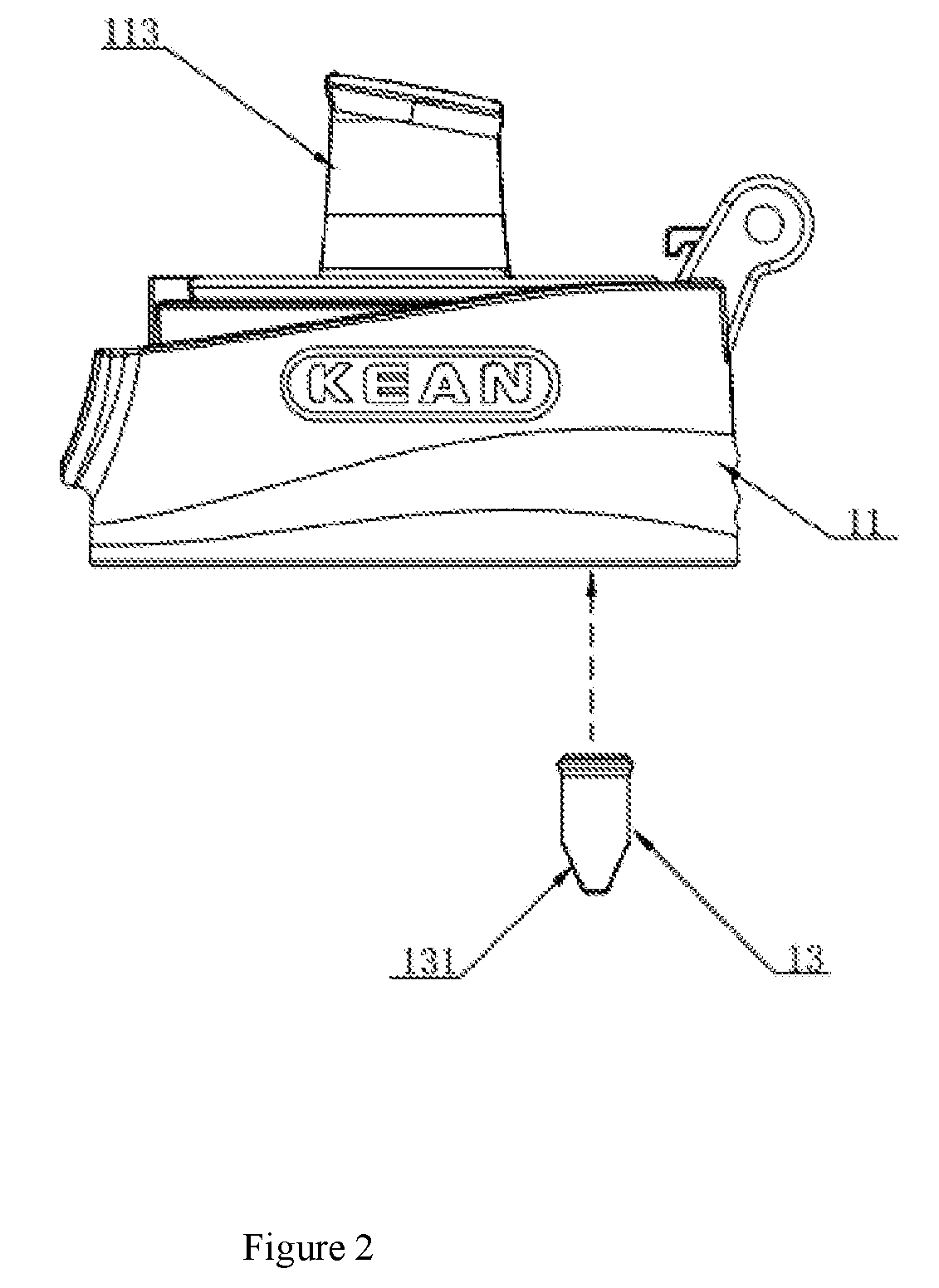

[0023]As shown in FIGS. 1-3, the new bottle cap 1 of the present invention comprises a cap body 11 and at least one air-return valve 13. A drinking port 113 and an air-return port 117 which is correspondingly disposed to the air-return valve 13 are disposed on the cap body 11. An anti-leakage valve is disposed in the drinking port 113. The place where the air-return port 117 is located extends inwardly to form a convex portion 111 in the cap body 11. One end of the air-return valve 13 is connected to the convex portion 111 in a matching way, and the other end of the air-return valve 13 is a closed port structure. In such case, when the air pressure in the cap body 11 is increased, the air can be prevented from flowing to the outside of the cap body 11 through the air-return valve 13. Meanwhile, when the air pressure outside of the cap body 11 is higher than...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com