Pneumatic Tire and Vehicle

a technology applied in the field of pneumatic tires and vehicles, can solve the problems of significant the reliability of estimation results may decline, and the decline in so as to prevent collisions between vehicles, suppress the decline of the recognition rate of vehicles by cameras, and high recognition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

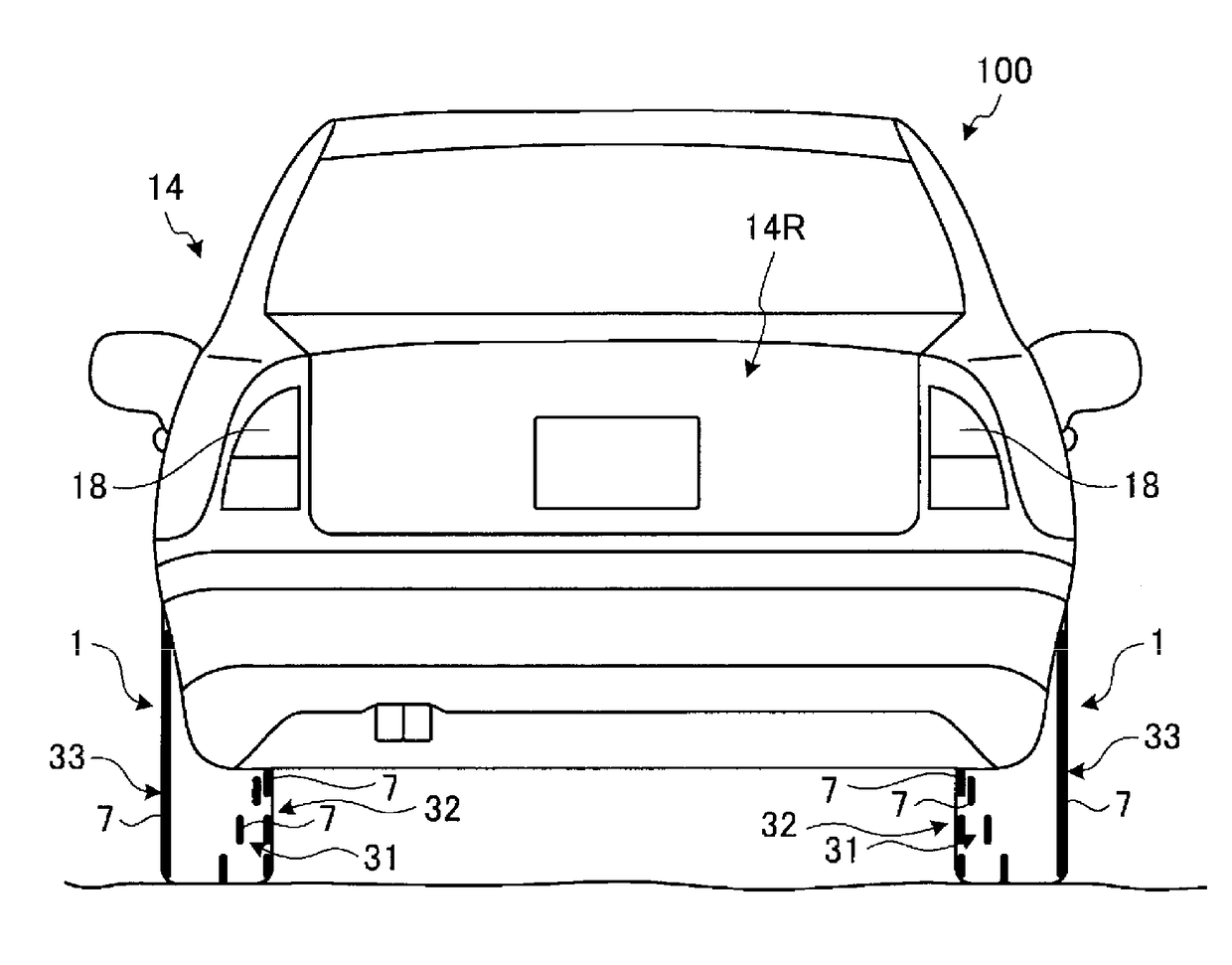

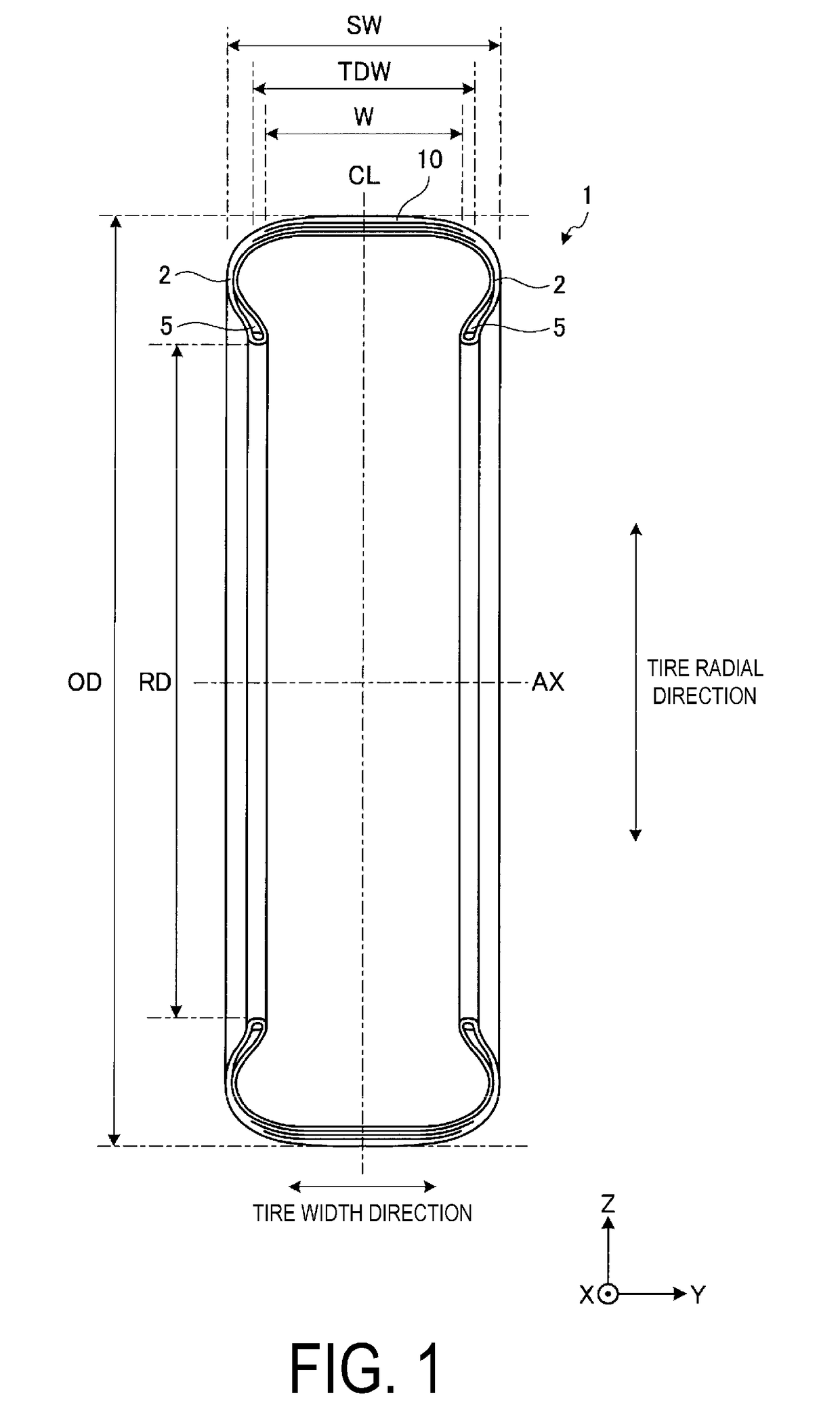

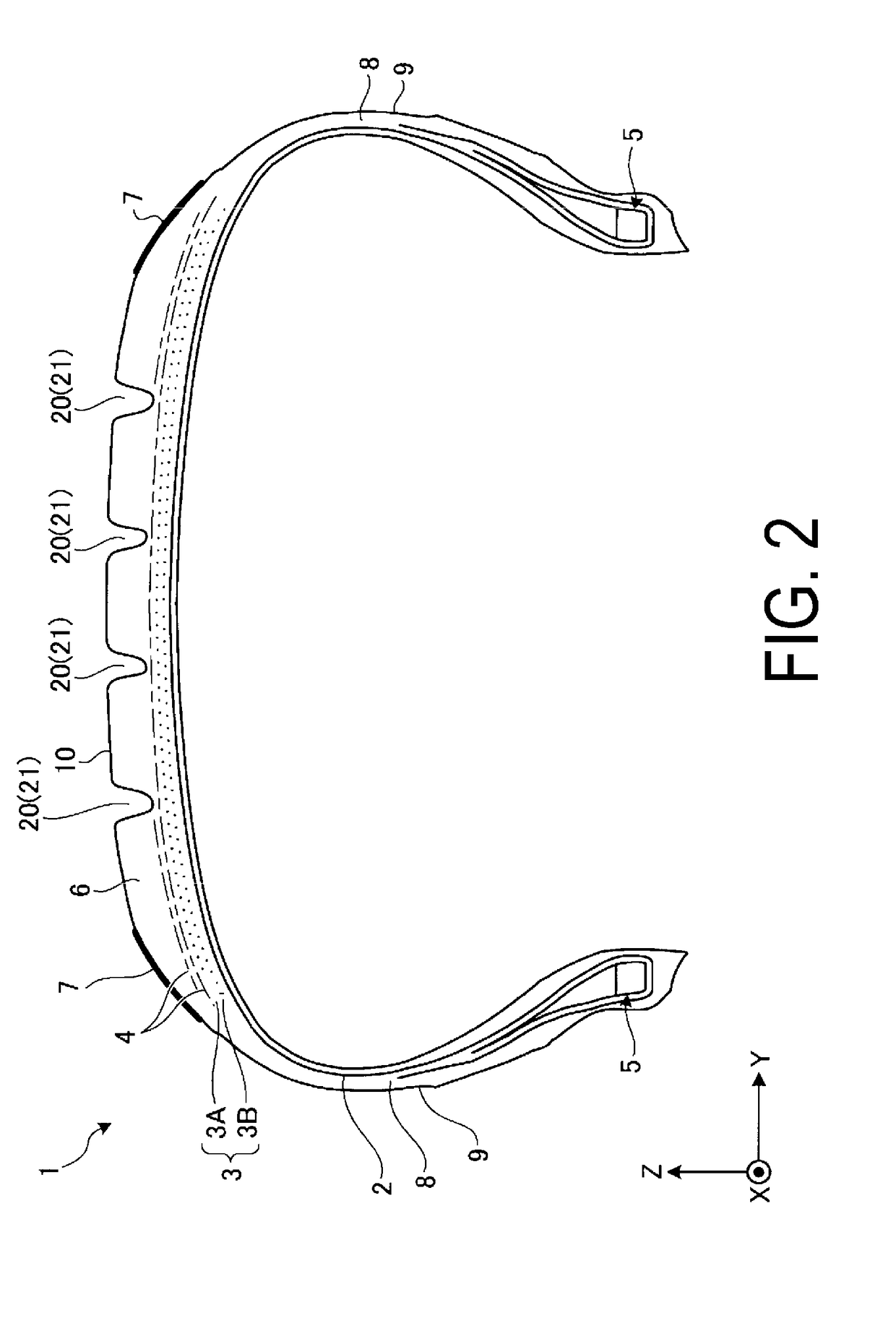

[0081]A first embodiment will be described. FIG. 1 is a cross-sectional view illustrating an example of a pneumatic tire 1 according to the present embodiment. FIG. 2 is an enlarged cross-sectional view of a portion of the pneumatic tire 1 according to the present embodiment. In the description below, the pneumatic tire 1 is also referred to as tire 1 for convenience.

[0082]The tire 1 is capable of rotation about a center axis (rotation axis) AX. FIGS. 1 and 2 each illustrate a meridian cross-section taken through the center axis AX of the tire 1. The center axis AX of the tire 1 is orthogonal to an equatorial plane CL of the tire 1.

[0083]In the present embodiment, the center axis AX of the tire 1 is parallel to the Y axis. That is, in the present embodiment, a direction parallel to the center axis AX is the Y-axis direction. The Y-axis direction is a vehicle width direction or a width direction of the tire 1. The equatorial plane CL passes through the center in the Y-axis direction ...

second embodiment

[0143]Next, a second embodiment will be described. In the description below, identical or substantially similar constituent portions to those of the above-described embodiments are assigned with the same reference numbers, and descriptions of those constituent portions are either simplified or omitted.

[0144]FIG. 8 is a drawing illustrating an example of a tire 1 according to the present embodiment. As illustrated in FIG. 8, the colored region 7 may be provided on the inner surface of the main groove 21. Note that the colored region 7 may be provided on all of the plurality of main grooves 21 (four in this example), or may be provided on a portion (e.g. two) of the main grooves 21.

[0145]The inner surface of the main groove 21 includes a bottom surface 21A, a first wall surface 21B disposed on a first side of the bottom surface 21A in the Y-axis direction, and a second wall surface 21C disposed on a second side of the bottom surface 21A. In the present embodiment, an angle θ formed by...

third embodiment

[0148]Next, a third embodiment will be described. In the description below, identical or substantially similar constituent portions to those of the above-described embodiments are assigned with the same reference numbers, and descriptions of those constituent portions are either simplified or omitted.

[0149]FIG. 9 is a drawing illustrating an example of a tire 1 according to the present embodiment. As illustrated in FIG. 9, in the present embodiment, the colored region 7 is provided on the surface between the +Y side ground contact edge portion 60 of the ground contact region of the tread portion 10 and the farthest portion 80 to the +Y side of the sidewall portion 9 disposed on the +Y side of the tread portion 10. The ground contact edge portion 60 is the edge portion of the tread ground contact width W. The portion 80 is the edge portion of the total tire width SW.

[0150]Note that in the example illustrated in FIG. 9, the colored region 7 is disposed on a first side (the +Y side) of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com