Biosensor and Method for Providing a Biosensor

a biosensor and biosensor technology, applied in the field of biosensors, can solve the problems of complex and cost-intensive production process of biosensors with more than one substrate surface, no adapted options, and no biosensor with more than one electrode, etc., and achieve the effect of less substrate material and simplified kinking process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0133]For the purposes of describing and defining the present invention it is noted that terms like “preferably”, “commonly”, and “typically” are not utilized herein to limit the scope of the claimed invention or to imply that certain features are critical, essential, or even important to the structure or function of the claimed invention. Rather, these terms are merely intended to highlight alternative or additional features that may or may not be utilized in a particular embodiment of the present invention.

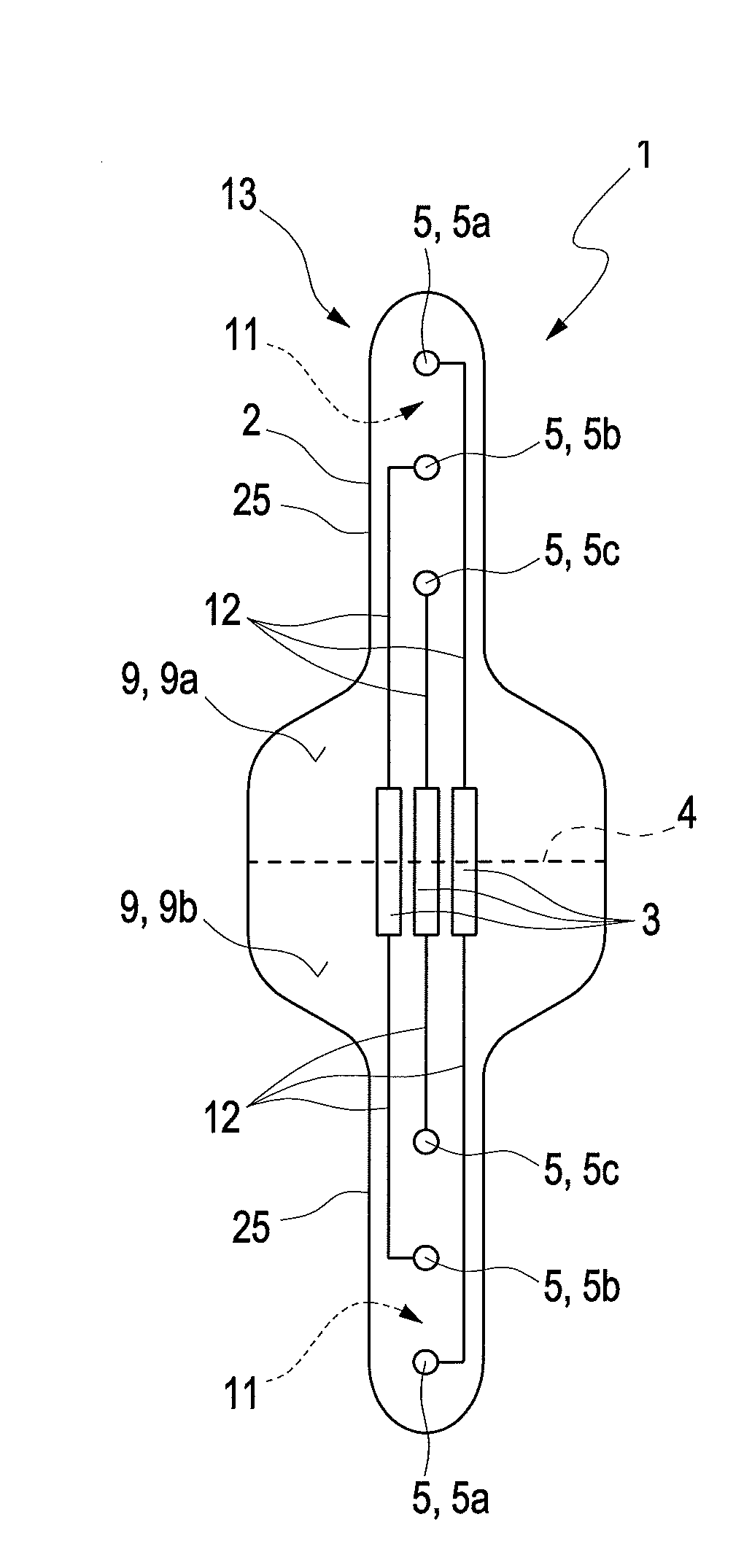

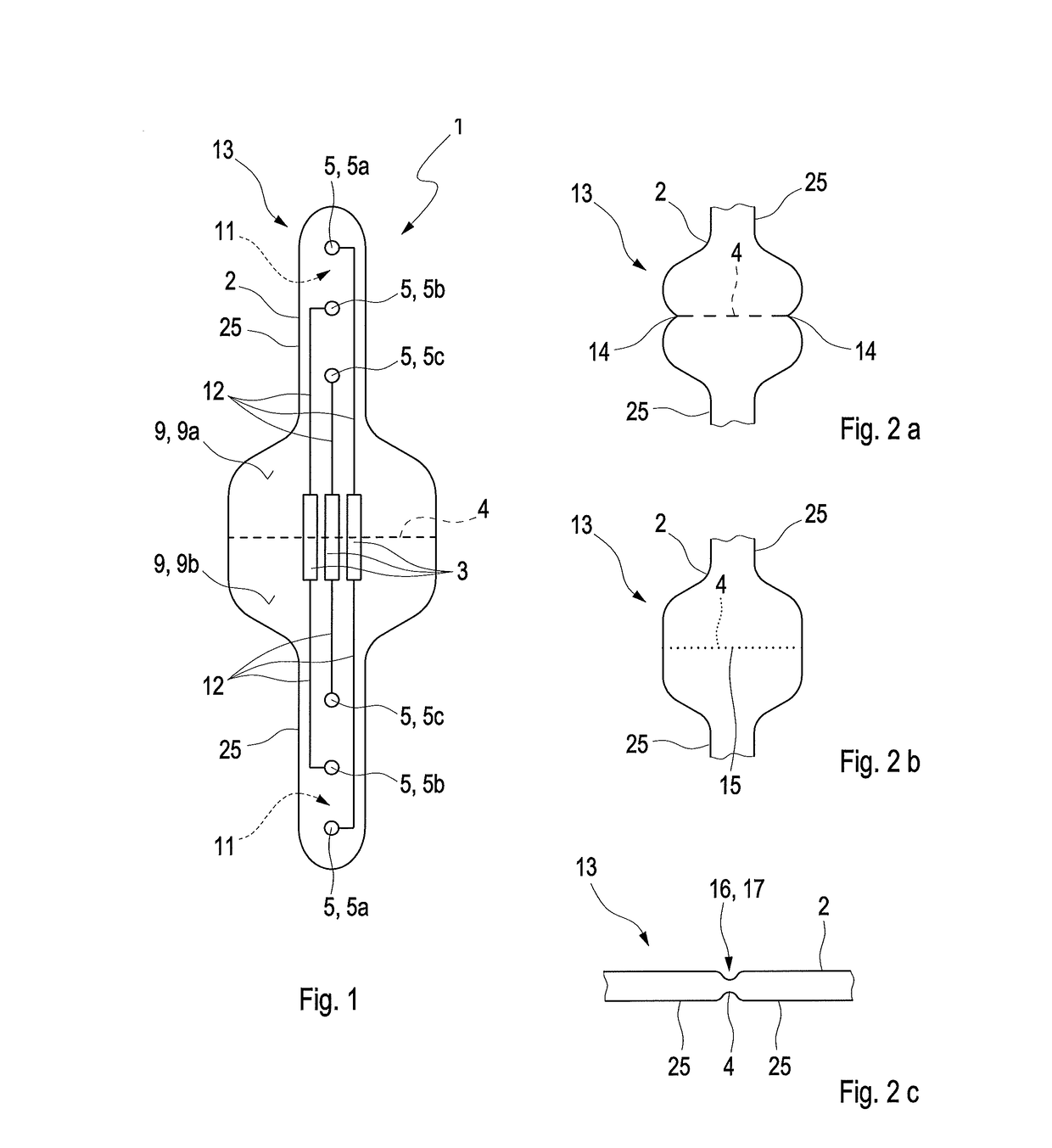

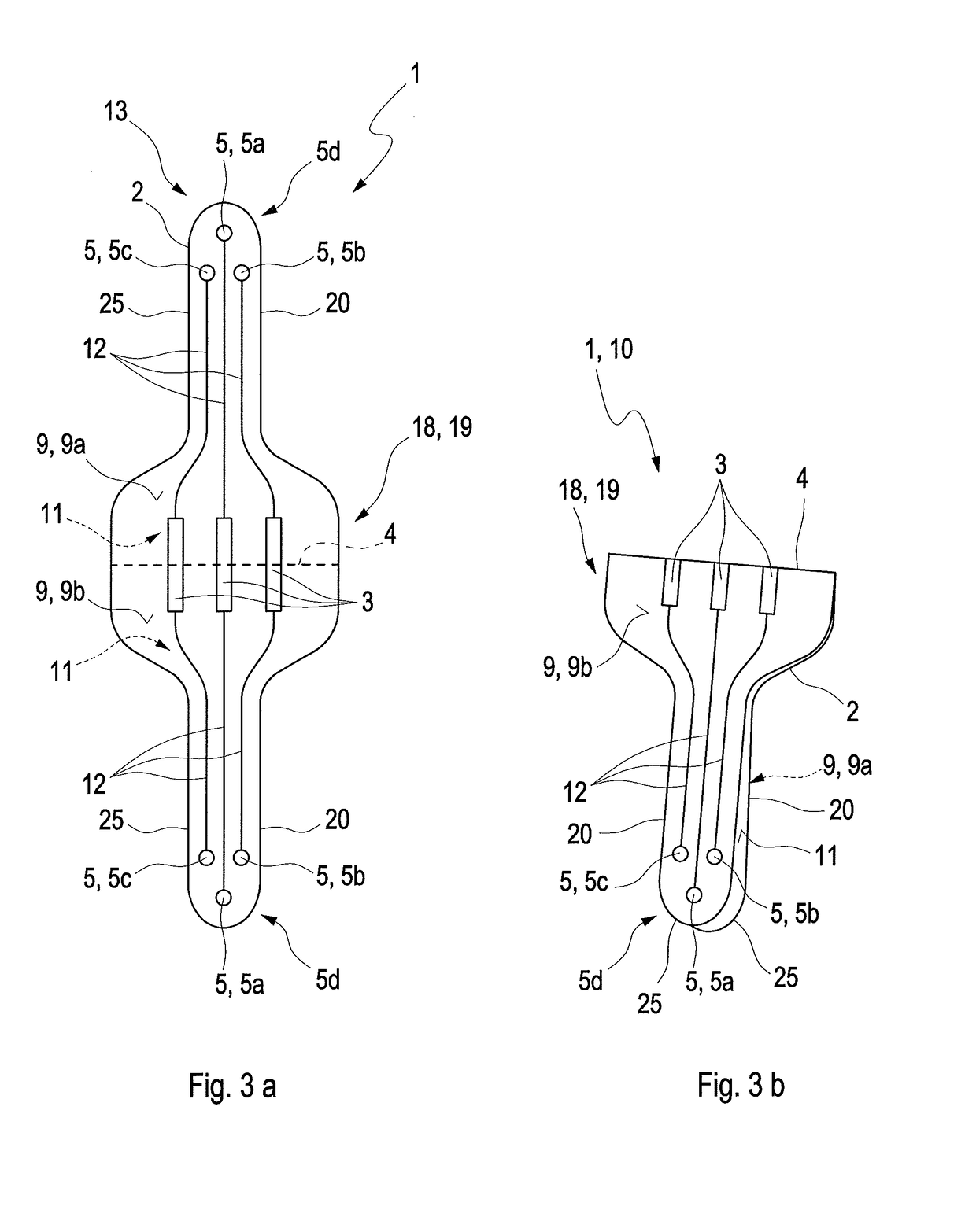

[0134]FIG. 1 schematically shows a biosensor 1 in an unkinked initial state, which simultaneously also constitutes an exemplary embodiment for a substrate blank 13. The biosensor 1 has a substrate 2, onto the one surface 9 of which contacting elements 3 have been applied, which are connected via conductor tracks 12 to electrodes 5, such as e.g. a working electrode 5a, a counter electrode 5b or a reference electrode 5c, on a first outer surface 9a of the substrate 2. The contacti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mean square roughness | aaaaa | aaaaa |

| mean square roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com