Fiberball batting and articles comprising the same

a technology of fiber ball and batting, which is applied in the field of fiber ball batting, can solve the problems of unfeasible or too cost-prohibitive, and not provide for desirable performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0083]The invention will now be illustrated, but not limited, by reference to the specific embodiment described in the following examples.

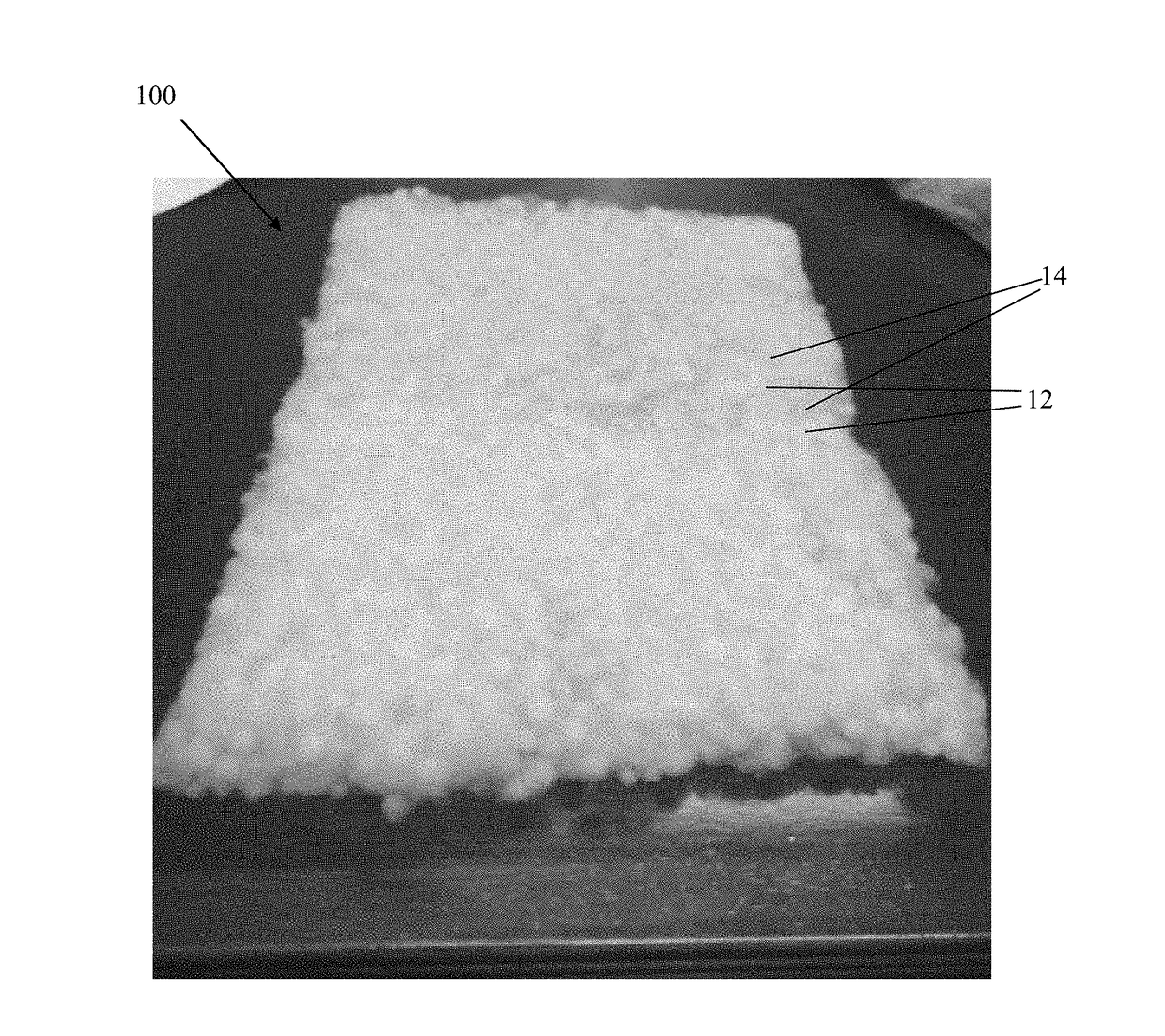

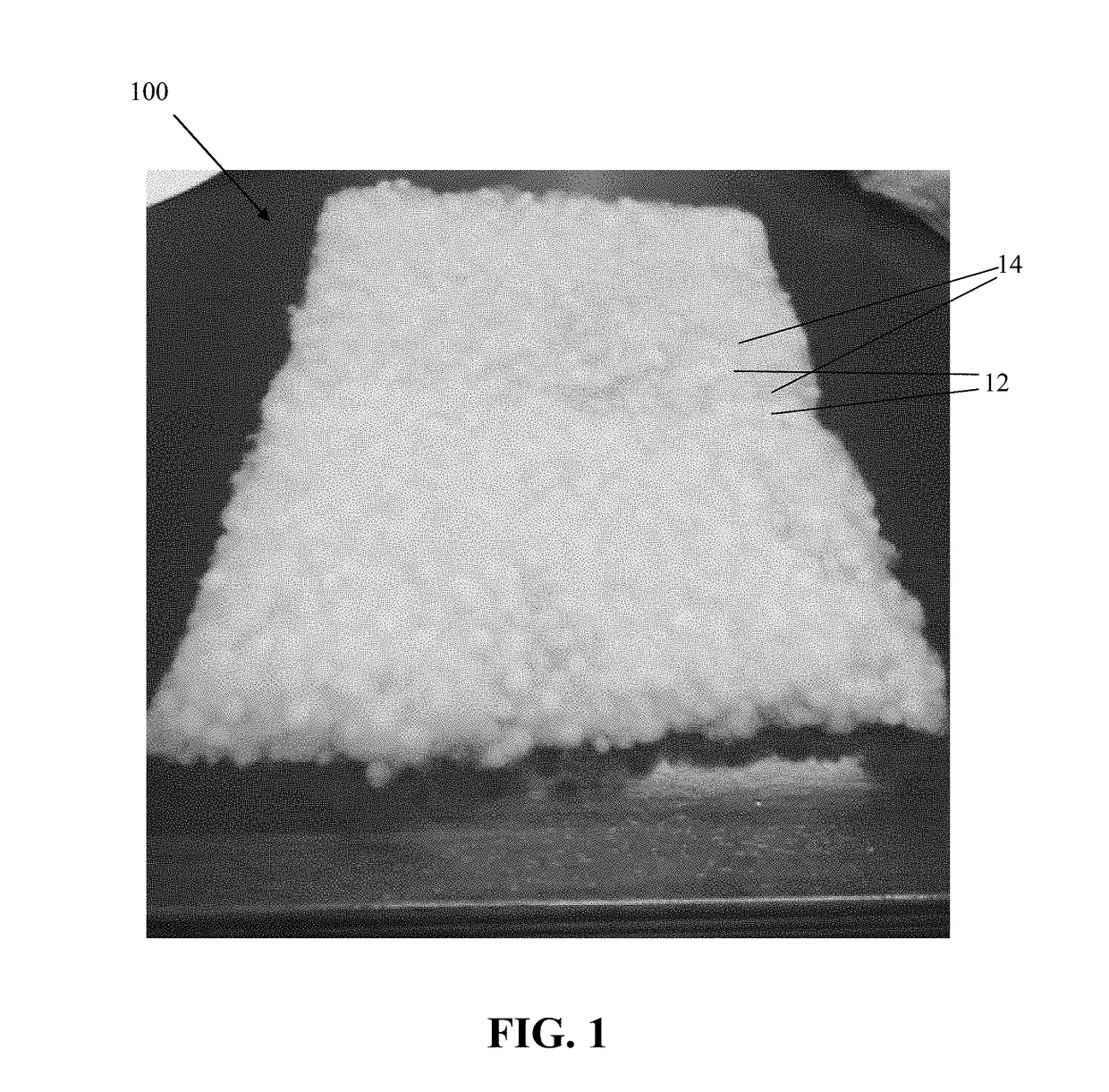

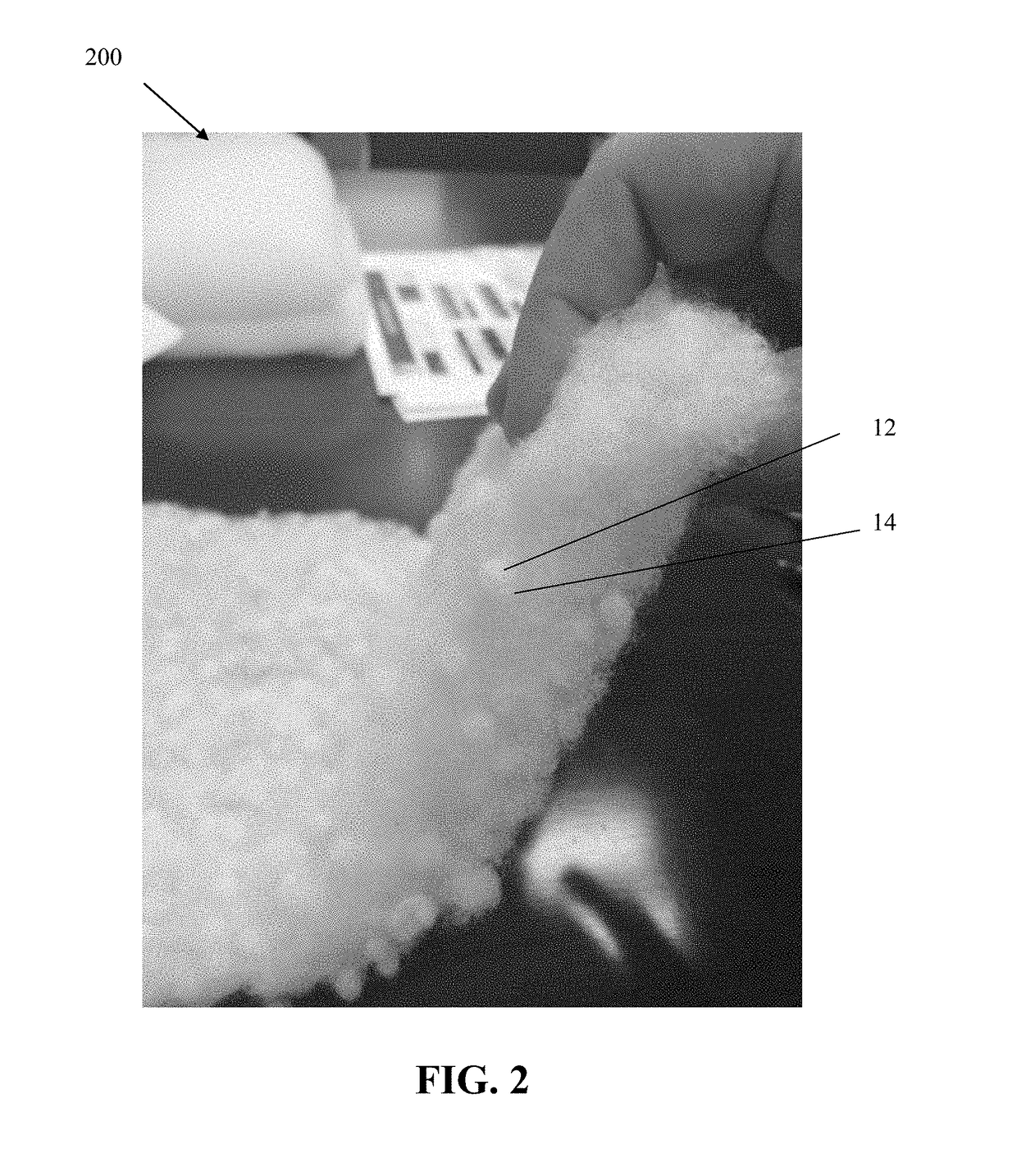

[0084]A sample batting is made according to the above method. The fiber mix for the sample is 90% 1.4 denier polyester fibers having a staple length of 28 mm, and 10% low-melt bi-component polyester / polyester binder fibers. The fiber mix is processed through a carding machine to obtain a non-woven web batting pre-cursor, which is heated at 110° C. to form an embodiment of the inventive batting. The final batting structure consists of 80% fiberballs having a diameter of 6 mm, and 20% plurality of portions of the nonwoven web that are adjacent to one or more fiberballs but that do not themselves comprise one or more fiberballs or any portion thereof. The batting has a weight of 175 gsm (grams per square meter), a thickness of 17.5 mm, and a density of 10 kg / m3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com