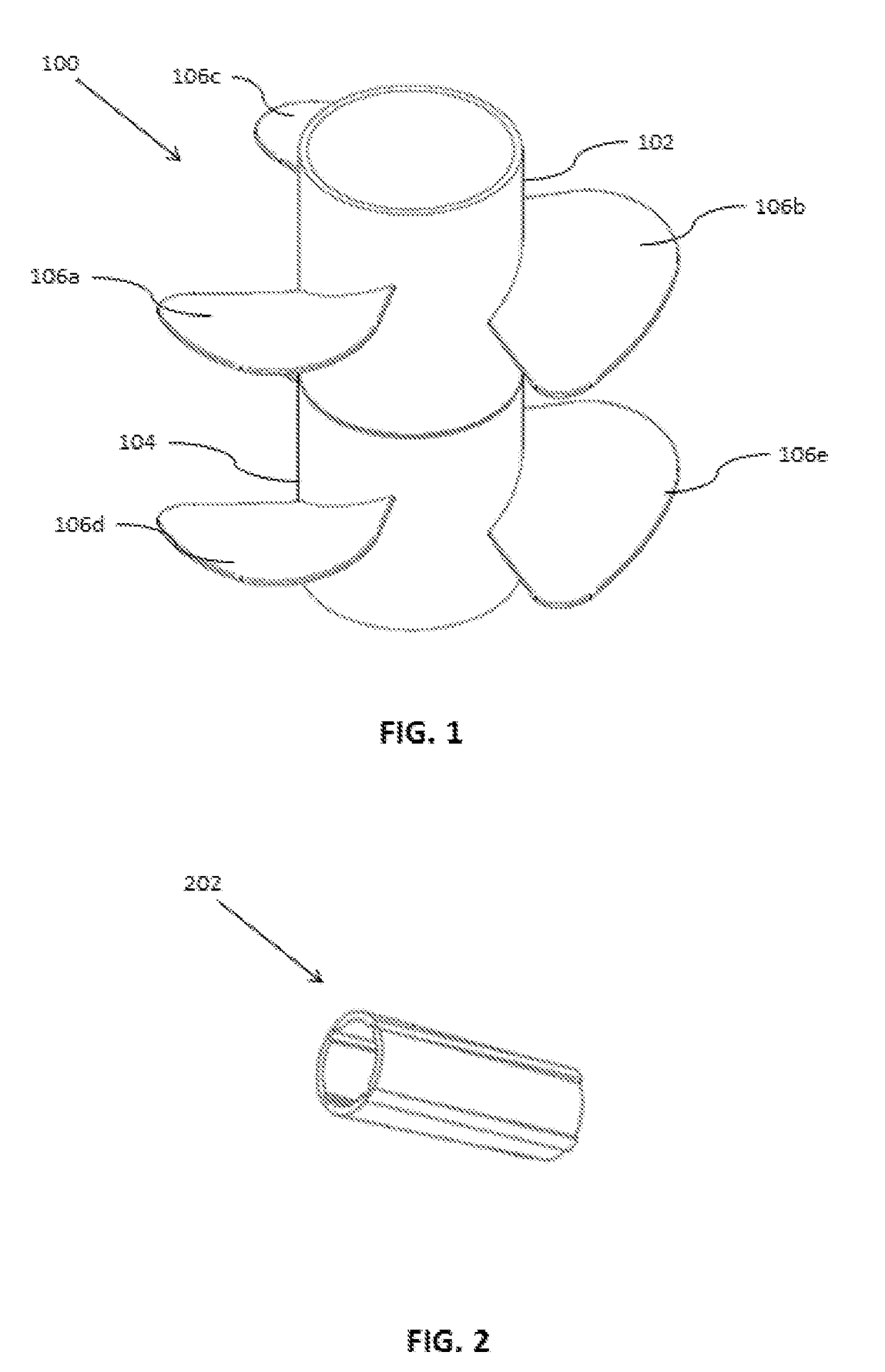

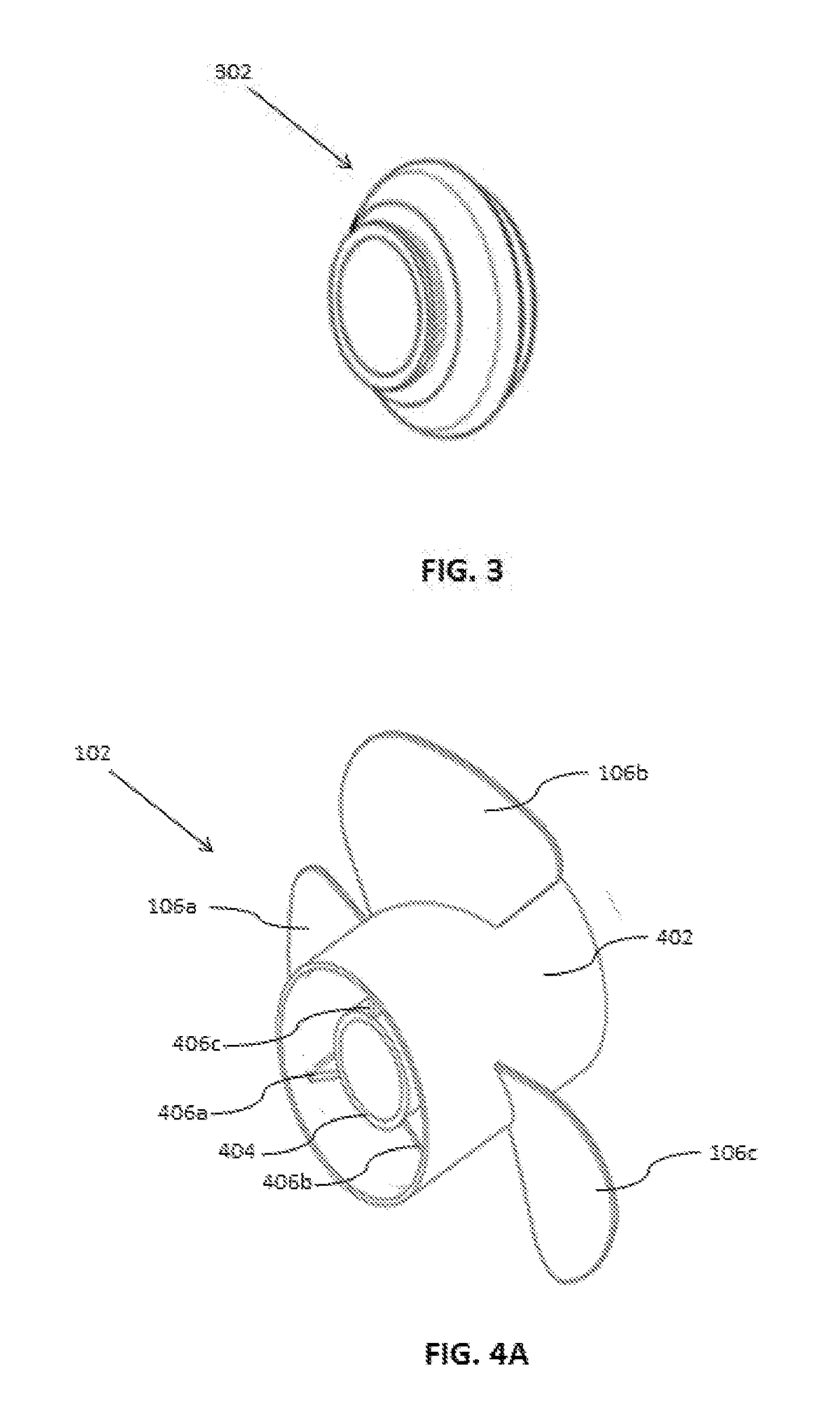

Propeller Assembly

a technology for propellers and watercraft, applied in watercraft propulsion, marine propulsion, vessel construction, etc., can solve the problems of long time to get up, difficult to pull out to the deeper end, and poor hole shot, etc., to achieve easy and inexpensive methods to increase the power of the boat motor, increase the thrust and power of the boat, and minimize or eliminate the effect of problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

[0057]A turbo 1 Yamaha brand prop (the leading prop) was employed to align with the inventive trailing propeller. The trailing propeller slides directly over the radial flanges of the leading propeller adjusting evenly so as alignment of the hubs is intact. The propeller assembly was placed on a 21 foot boat and taken to water having 6″ of depth to create a hole shot situation. It was found that the 21′ boat while standing in 6″ of water was able to move out of the water in ½ of the boat length.

[0058]Comparative: The same boat was in the hole shot with the standard turbo 1 Yamaha brand prop, and no trailing inventive propeller to form the assembly. The boat was not able to get on plane at all, or out of the water, and needed to drive in circles to get itself out of the hole shot. When compared to a high performance engine (hole shot prop) the distance to plane was 4 times as long in the above situation. In about 12″ of water, this depth still considered shallow, the 21′ test boat re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com