Surface-treated steel sheet

a technology of surface-treated steel and steel sheets, applied in the direction of coatings, electrolytic coatings, electrolytic inorganic material coatings, etc., can solve the problems of insufficient effect of coating film formation, workability or weldability degradation, and increase manufacturing costs, and achieve excellent barrier properties and excellent coating film adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0203]“Test Results of Vanadium-Containing Surface-Treated Steel Sheet”

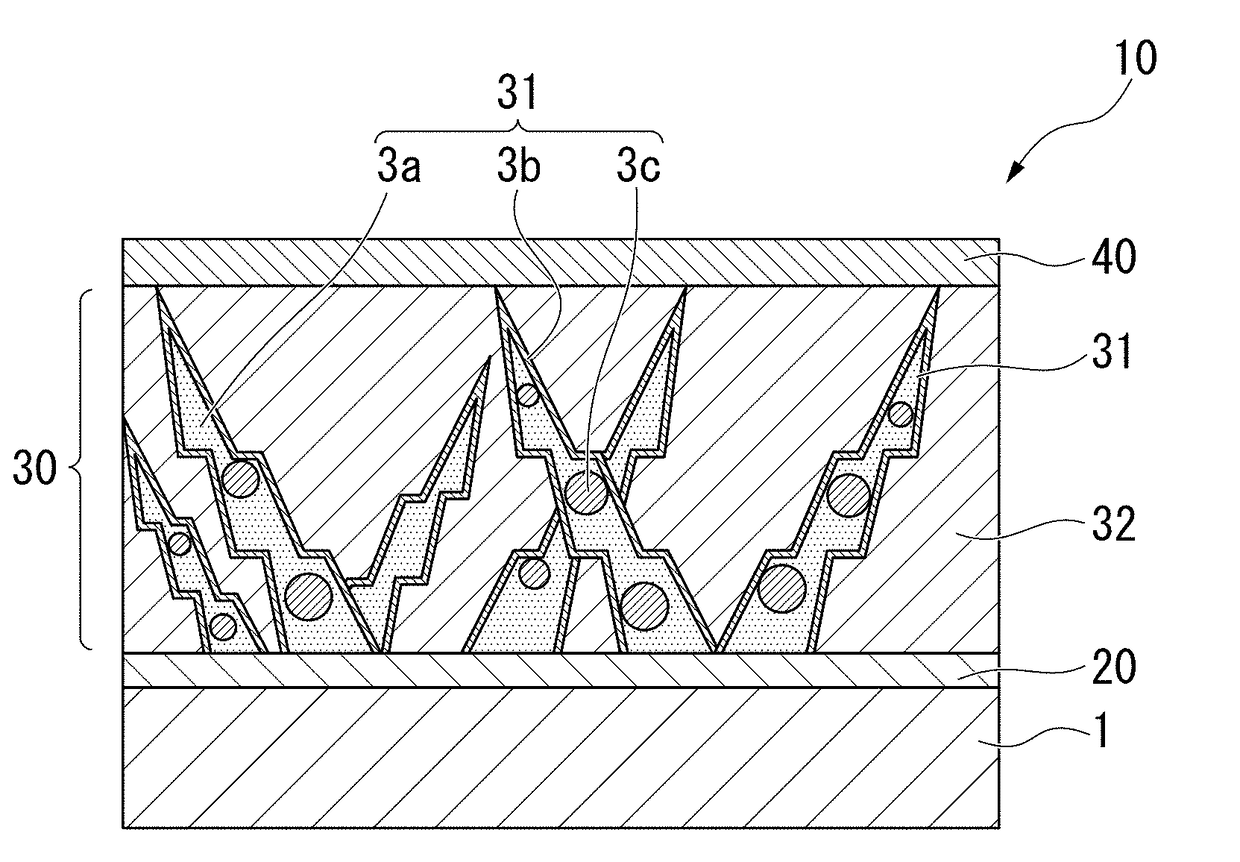

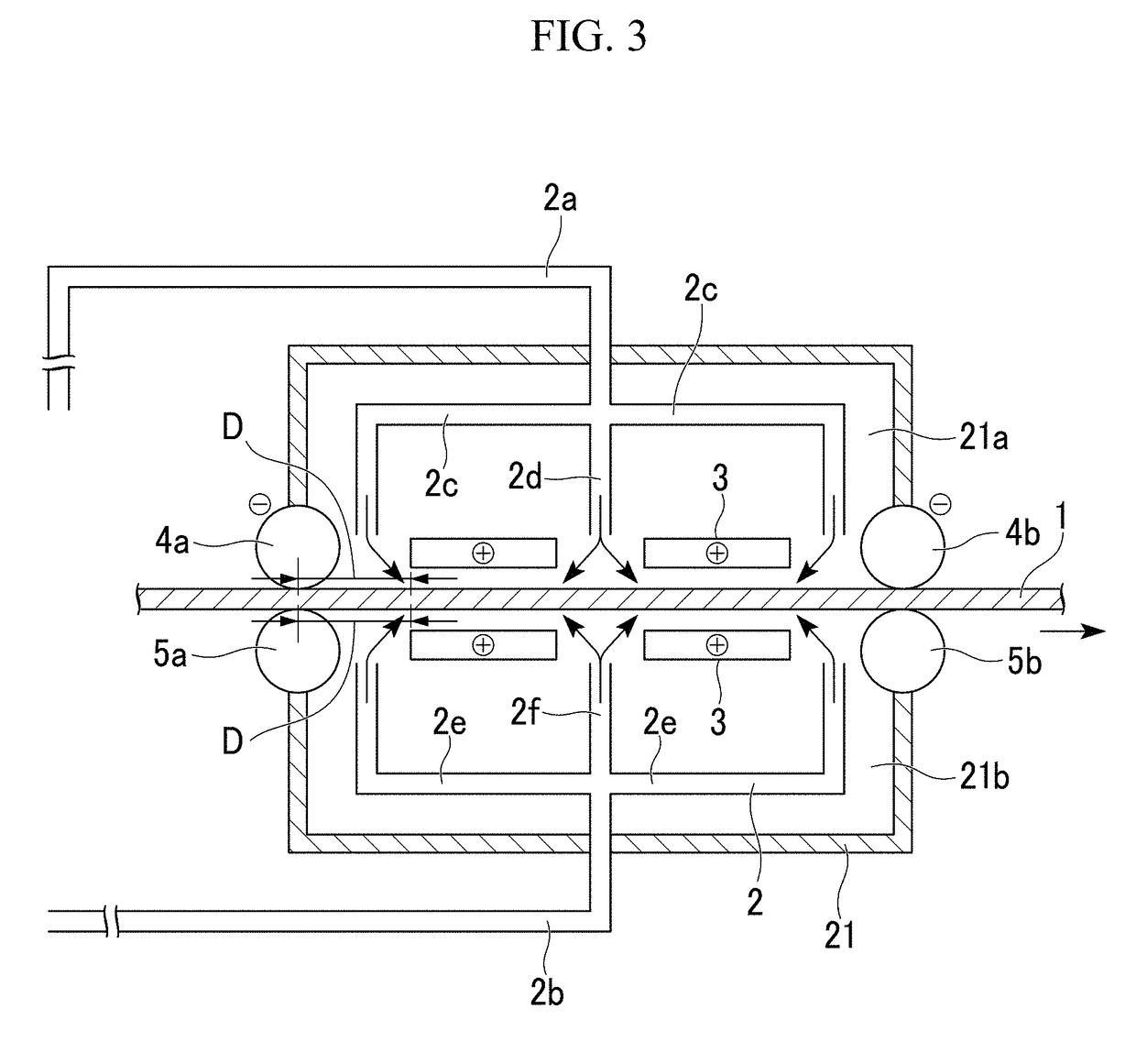

[0204]A surface-treated steel sheet having plating layers including vanadium on both surfaces of a steel sheet was produced using the plating apparatus shown in FIG. 3 and a method described below and was evaluated.

[0205]A plating bath in a fluid state was prepared by circulating a plating bath having a plating bath composition, a temperature, and a pH shown in Table 1 at a relative average flow rate of 100 m / min.

TABLE 1Plating bath composition (mol / l)Plating bathV(V4+) +temperaturePlatingZn2+(VO2−)Na+Ni2−(° C.)bath pHBath (Zn—V)1.00.81.30.1502.2Bath (Zn)1.0———501.0

[0206]As the steel sheet, a 0.5 mm-thick SPCD steel sheet which is a drawing quality cold-rolled steel sheet defined by JIS G 3141 was used.

[0207]A pretreatment (nickel plating) was carried out on the steel sheet, and the steel sheet was used as a negative electrode.

[0208]In the pretreatment, first, as a plating bath for the nickel plating, ion exchang...

example 2

[0256]“Test Results of Film-Forming Vanadium-Containing Surface-Treated Steel Sheet”

[0257]A coating composition for forming films was prepared by stirring and dispersing the organic resin (R), the phosphoric acid compound (P), the carbon black (C), the organic silicon compound (W), the fluoro metal complex compound (F), the isocyanate compound (I), and the polyethylene wax (Q) shown in Table 8 in water which was a solvent at amounts (% by mass of the solid contents) shown in Table 9 and Table 10 using a coating disperser.

TABLE 8ReferenceKindSymbolNames of compounds and the likeOrganic resinRPolyurethane resin (SUPERFLEX620 manufactured by DKS Co., Ltd.)Phosphoric acid compoundP1Phosphoric acidP2Ammonium dihydrogen phosphateCarbon blackCEMF BLACK HK-3 manufactured by Toyocolor Co., Ltd.Organic silicon compoundW13-AminopropyltriethoxysilaneW23-GlycidoxypropyltrimethoxysilaneFluoro metal complex compoundFHexafluorotitanic acidIsocyanate compoundIBlocked isocyanate (Aqua BI220 manufactu...

example 3

[0313]“Test Results of Zirconium-Containing Surface-Treated Steel Sheet”

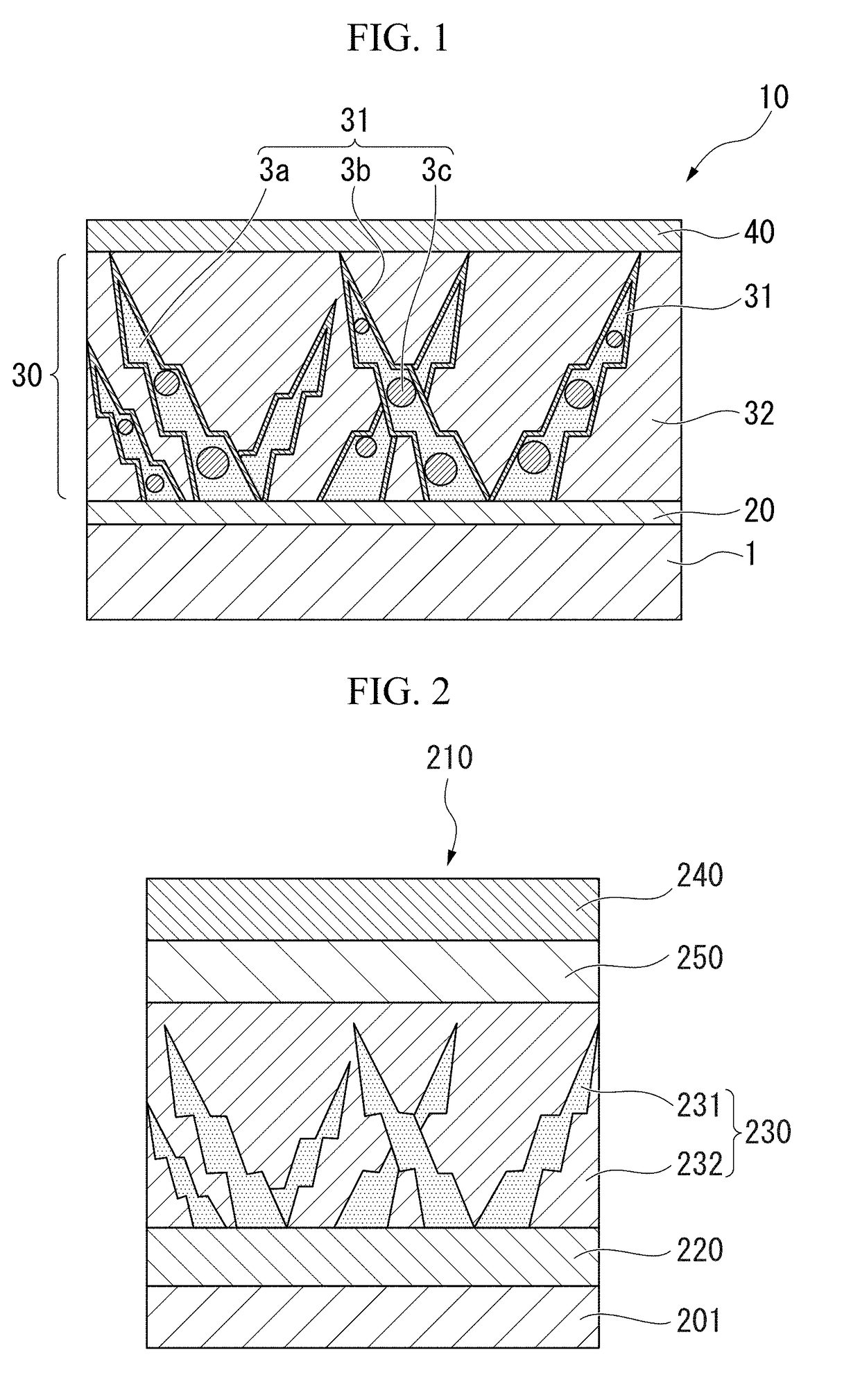

[0314]A surface-treated steel sheet having plating layers including zirconium on both surfaces of a steel sheet was produced using the plating apparatus shown in FIG. 2 and a method described below and was evaluated.

[0315]Meanwhile, the same facts as in Example 1 will not be described.

[0316]A plating bath in a fluid state was prepared by circulating a plating bath having a plating bath composition, a temperature, and a pH shown in Table 13 at a relative average flow rate of 100 m / min.

TABLE 13Plating bath composition (mol / l)Plating bathZr(Zr4+) +temperaturePlatingZn2+(ZrO2+)Na+Ni2−(° C.)bath pHBath (Zn—Zr)1.00.51.30.1501.5Bath (Zn)1.0———501.0

[0317]In addition, a pretreatment (nickel plating) was carried out using the steel sheet as a negative electrode. In the base-material-forming process and the upper layer plating process, the electric conduction times were set to times shown in Table 14 and Table 15, the curr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com