Cleaner head for a vacuum cleaner

a vacuum cleaner and cleaner head technology, applied in the direction of suction cleaners, cleaning equipment, suction nozzles, etc., can solve the problem of difficult to steer the cleaner head in a particular direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

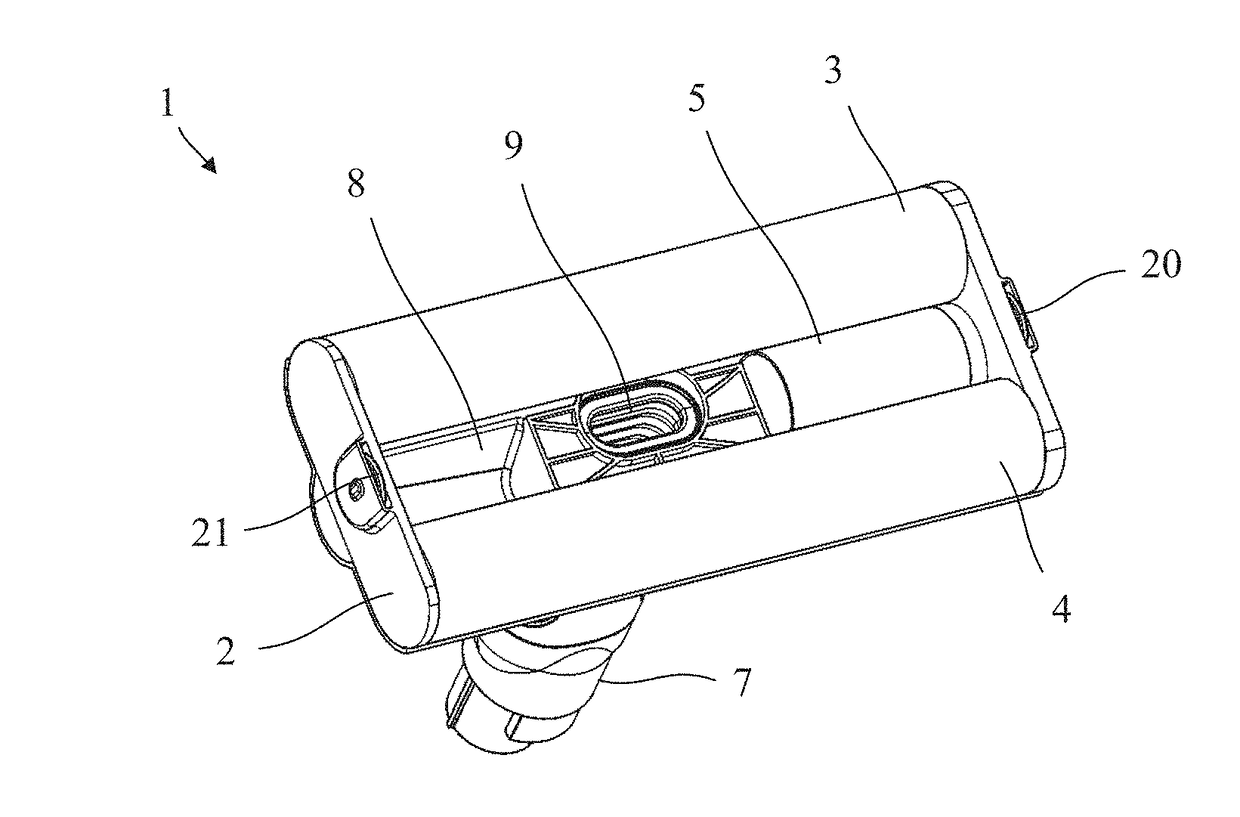

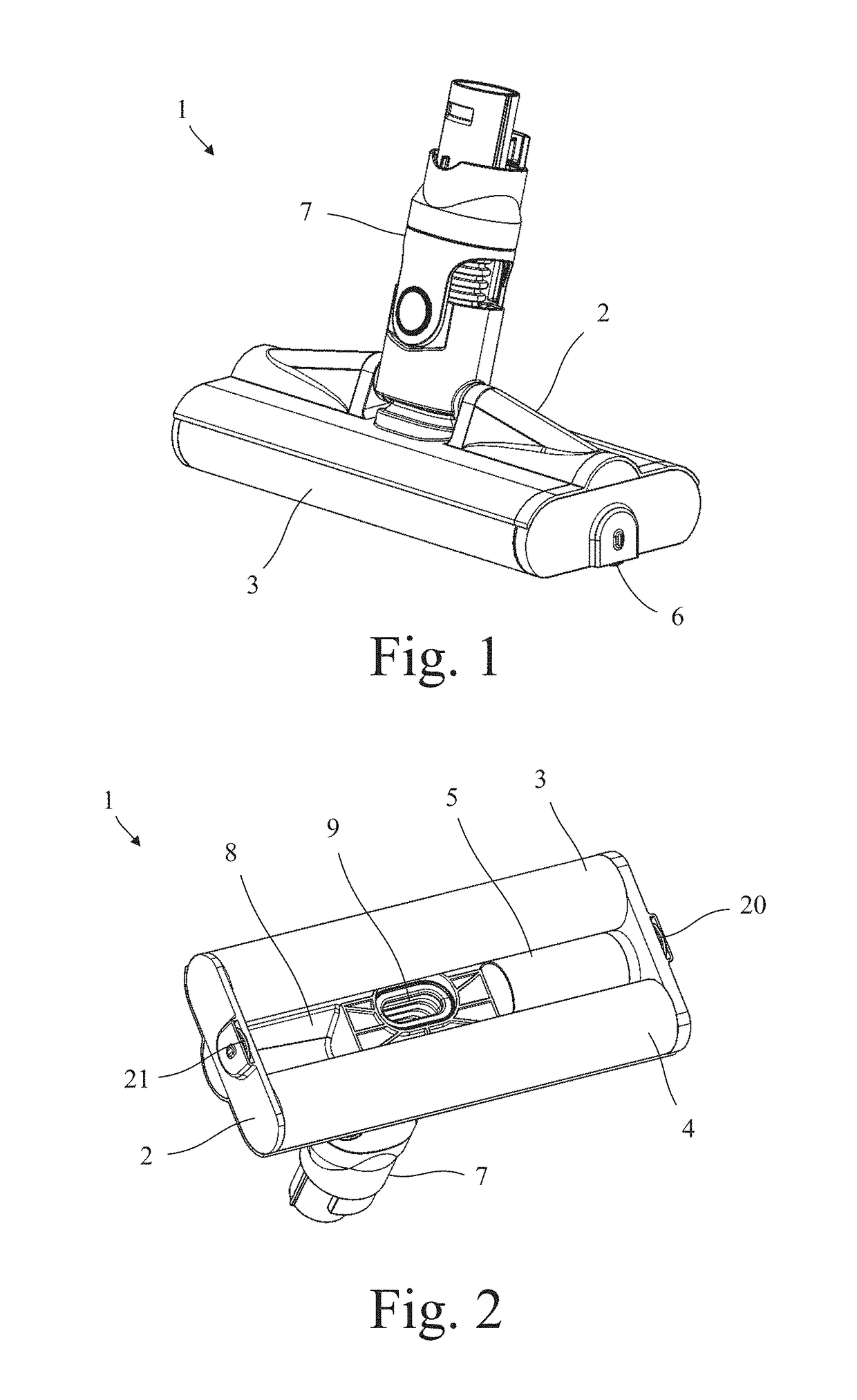

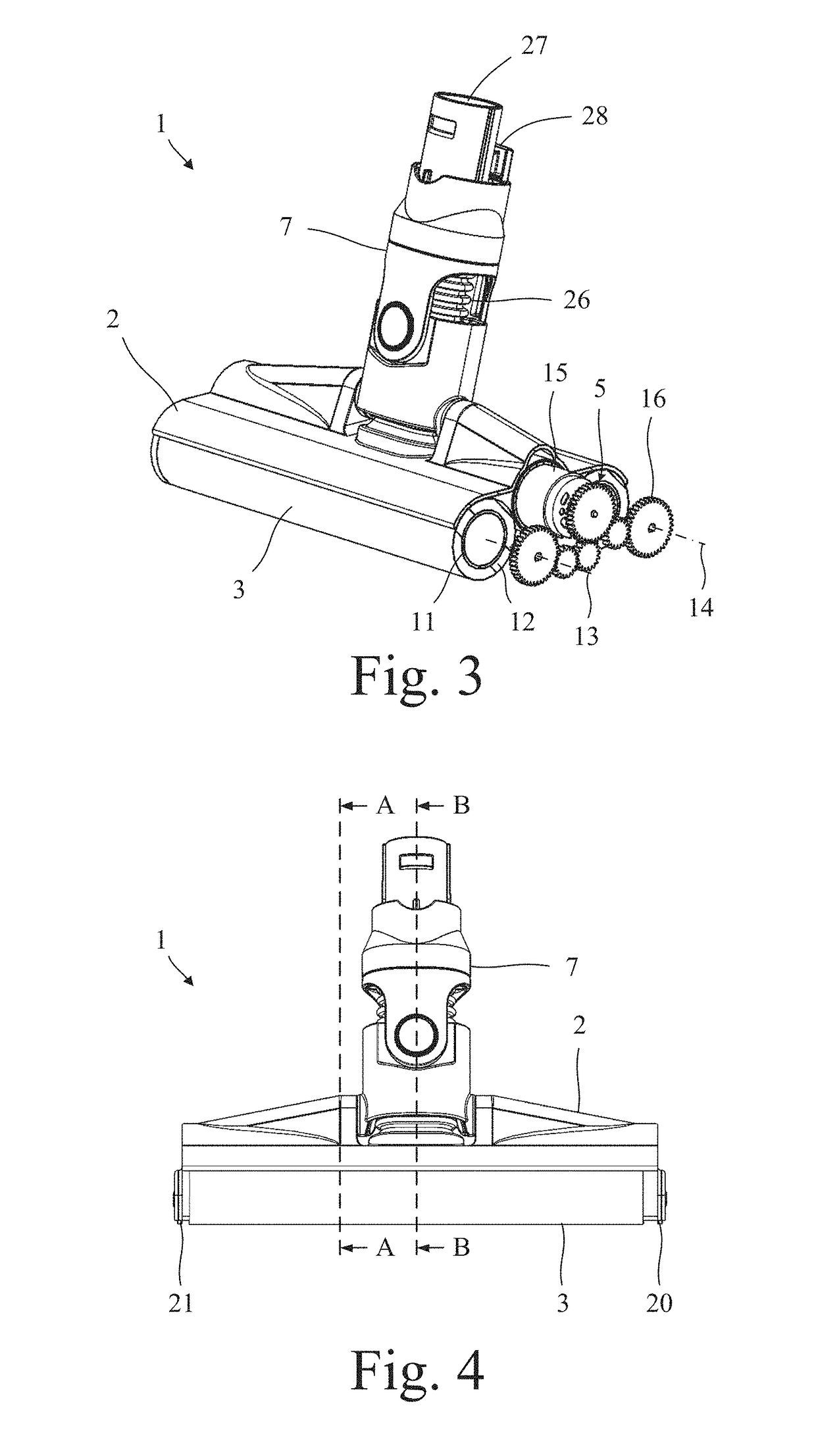

[0018]The cleaner head 1 of FIGS. 1 to 6 comprises a housing 2, a pair of agitators 3,4, a drive assembly 5, a wheel assembly 6, and a neck 7.

[0019]The housing 2 defines a chamber 8 within which the agitators 3,4 are rotatably mounted. Each agitator 3,4 comprises an elongate body 11 to which bristles, flicker strips or other means 12 for agitating a surface are attached. In the present embodiment, the elongate body 11 is covered with a plush of synthetic fibres 12. The two agitators 3,4 rotate in opposite directions about axes of rotation 13,14 that are parallel to one another. More particularly, the agitators 3,4 rotate in directions that act to sweep dirt from the floor into the chamber 8. Consequently the front agitator 3 in FIGS. 5 and 6 rotates in a counter-clockwise direction and the rear agitator 4 rotates in a clockwise direction.

[0020]The drive assembly 5 is mounted within the housing 2 and comprises an electric motor 15 and a gear train 16 for transmitting torque generated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com