Preform, a container, and a method for fabrication of a preform

a technology of preform and container, which is applied in the field of preform, can solve the problems of undesirable stresses in the preform material and molding apparatus, the method of fabricating preform known in the prior art, and the inability to meet the requirements of the preform material, and achieve the effect of better conformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0067]FIG. 1 depicts a preform according to the invention. In a first step for fabrication of the preform 100 of FIG. 1 a plurality of preform segments 101-103 are provided, each of which is substantially ring-shaped and defines a portion of the preform 100. In this embodiment, the preform 100 comprises a mouth segment 101, a body segment 102, and a tail segment 103. Preferably, the preform segments 101-103 are symmetric about a longitudinal axis 104 of the preform 100.

[0068]In a second step for fabrication of the preform 100, the preform segments 101-103 are positioned so as to be in continuous contact with each other along at least one edge of said preform segments 101-103. In this embodiment, an edge of the mouth segment 101 is in continuous contact with an edge of the body segment 102 along a first seam 105. A second edge of the body segment 102 is in continuous contact with an edge of the tail segment 103 at a second seam 106. The arrangement of the preform segments 101-103 in ...

third embodiment

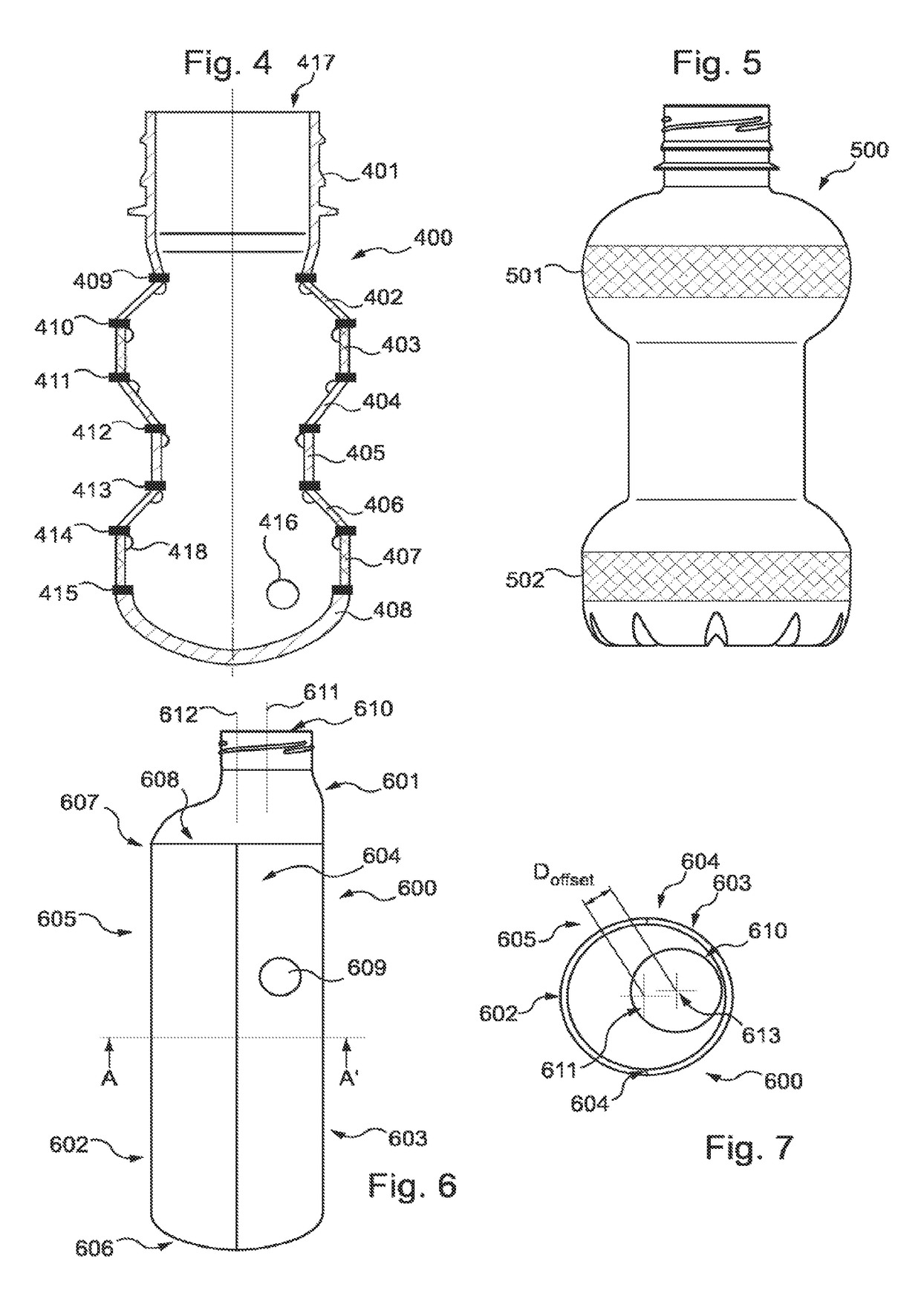

[0079]FIG. 4 depicts a preform according to the invention. The preform 400 is fabricated from eight preform segments 401-408, which are disposed in contact with each other as shown and bonded along their edges at several seams 409-415. The resultant preform 400 is thus provided with a cavity 416 in communication with an open end 417. The preform 400 is in a shape substantially resembling an hourglass, which when expanded will yield a substantially hourglass-shaped container.

[0080]The preform segments 401-408 are further provided with ribs 418 upon their internal surfaces. These ribs 418 serve to add additional structural strength and resistance to the container fabricated from the preform 400.

[0081]While FIG. 4 depicts an example of a preform in an hourglass shape, the method of the invention permits many other shapes, textures and contours to be realized in preforms, and by extension in containers. The invention thus offers a greatly increased variety of possible container shapes a...

fourth embodiment

[0084]FIG. 6 depicts a preform according to the invention.

[0085]The preform 600 is fabricated from three preform segments: a substantially ring-shaped neck segment 601, and two body segments 602 and 603. The body segments 602 and 603 are substantially identical, and are bonded along a longitudinal seam 604 to create a preform body 605 which is substantially tubular and closed at a first end 606. The neck segment 601 is bonded to the preform body 605 at a second end 607, along a circumferential seam 608, thereby producing the preform 600 which defines a cavity 609.

[0086]The neck segment 600 is provided with a mouth 610 with a centerline 611. The preform mouth centerline 611 is offset from the preform body centerline 612, which is shown in greater detail in Section A-A of FIG. 7.

[0087]FIG. 7 is a section view of the cavity 609 of the preform 600, looking towards the inside surface of the neck segment 601. The mouth 610 has a mouth center 613 which corresponds to the preform mouth cent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

| thicknesses | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com