Method for forming braille text and inkjet printer

a technology of inkjet printer and braille text, which is applied in the field of braille text and inkjet printer, can solve the problems of difficult to produce 3d signage in a simple and quick manner, and difficult to produce braille text in a simple and quick manner, and achieve the effect of easy and quick braille tex

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first preferred embodiment

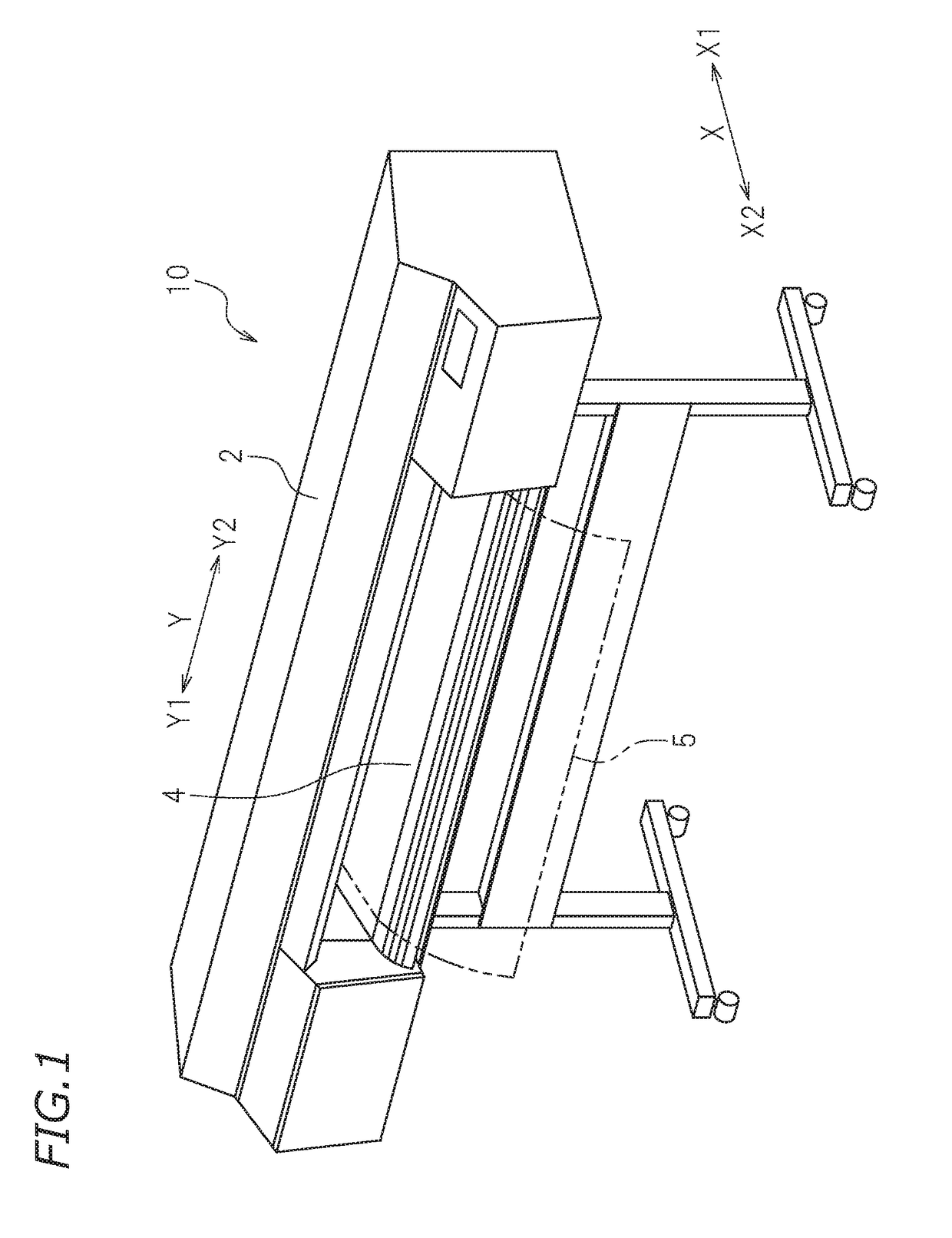

[0024]FIG. 1 is a perspective view of an inkjet printer 10 according to a first preferred embodiment of the present invention. The inkjet printer 10 includes a casing 2, and a platen 4 that supports a recording medium 5.

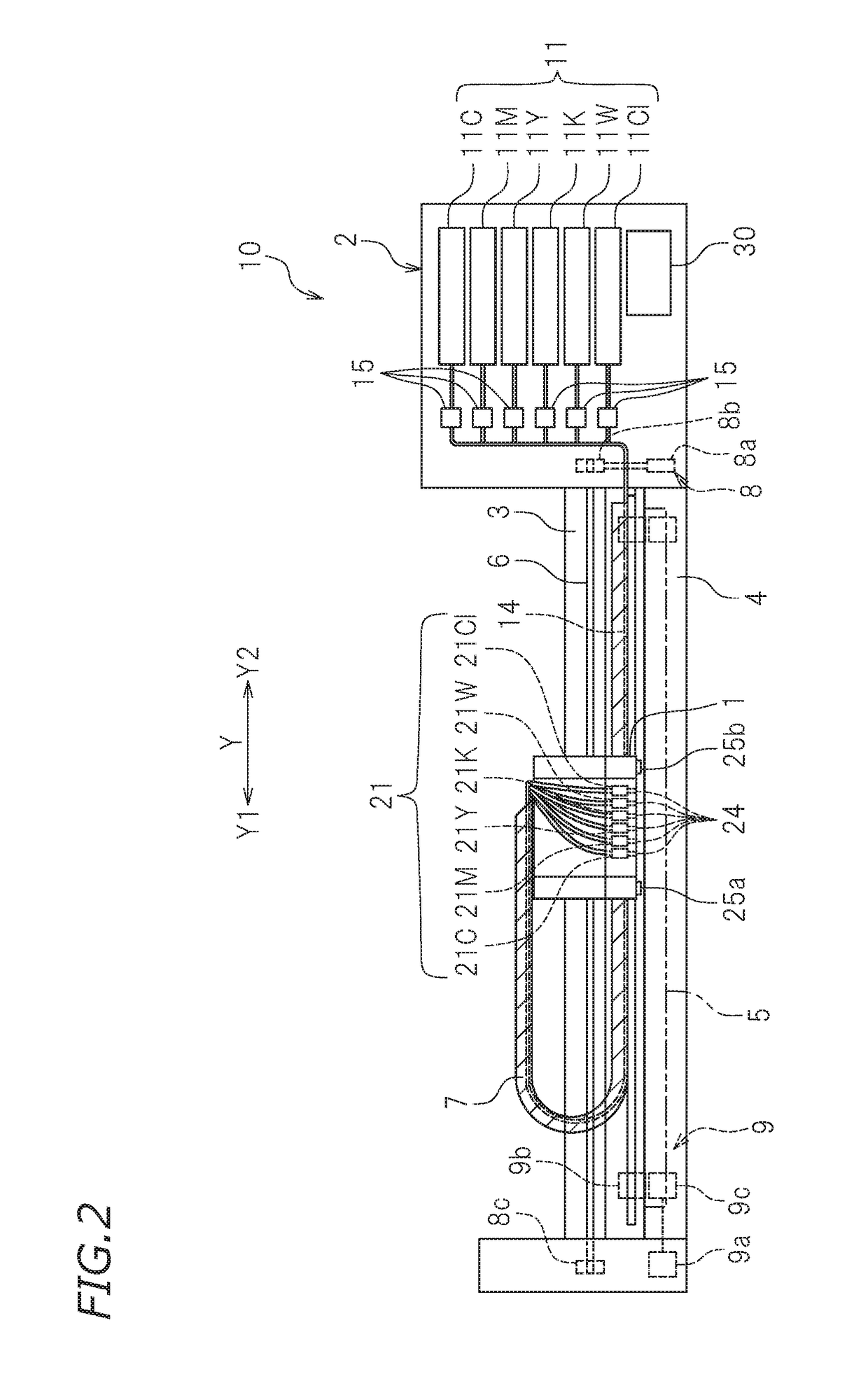

[0025]FIG. 2 is a front view showing the main portion of the inkjet printer 10. The main portion is arranged inside the casing 2. The inkjet printer 10 includes a guide rail 3 provided in the casing 2. The guide rail 3 extends in the primary scanning direction Y and is secured on the left wall and the right wall of the casing 2. A carriage 1 is in engagement with the guide rail 3. The carriage 1 includes an ink discharge head 21 mounted thereon.

[0026]FIG. 3 shows a configuration of the bottom surface of the carriage 1. As shown in FIG. 3, the ink discharge head 21 is mounted on the bottom surface of the carriage 1. The ink discharge head 21 includes six ink heads 21C, 21M, 21Y, 21K, 21W and 21C1. The ink heads 21C, 21M, 21Y, 21K, 21W and 21C1 are arranged in line in ...

second preferred embodiment

[0071]In a second preferred embodiment of the present invention, the inkjet printer 10 forms a 3D print on the recording medium 5. FIG. 8 shows an exemplary 3D print formed by the inkjet printer 10 according to the present preferred embodiment. The 3D print shown in FIG. 8 is a 3D signage 110. The entirety of the 3D signage 110 shown in FIG. 8 is raised from the recording medium 5. Moreover, non-hatched portions are sunken relative to hatched portions. The 3D signage 110 represents a predetermined sign by the planar shape defined by boundaries between hatched portions and non-hatched portions. The boundaries are preferably rounded. The inkjet printer 10 according to the present preferred embodiment preferably forms a 3D print, such as the 3D signage 110 of FIG. 8, for example. There is no particular limitation on the type of ink used to form a 3D print, but a color ink and a clear ink are preferably used in the example to be discussed below.

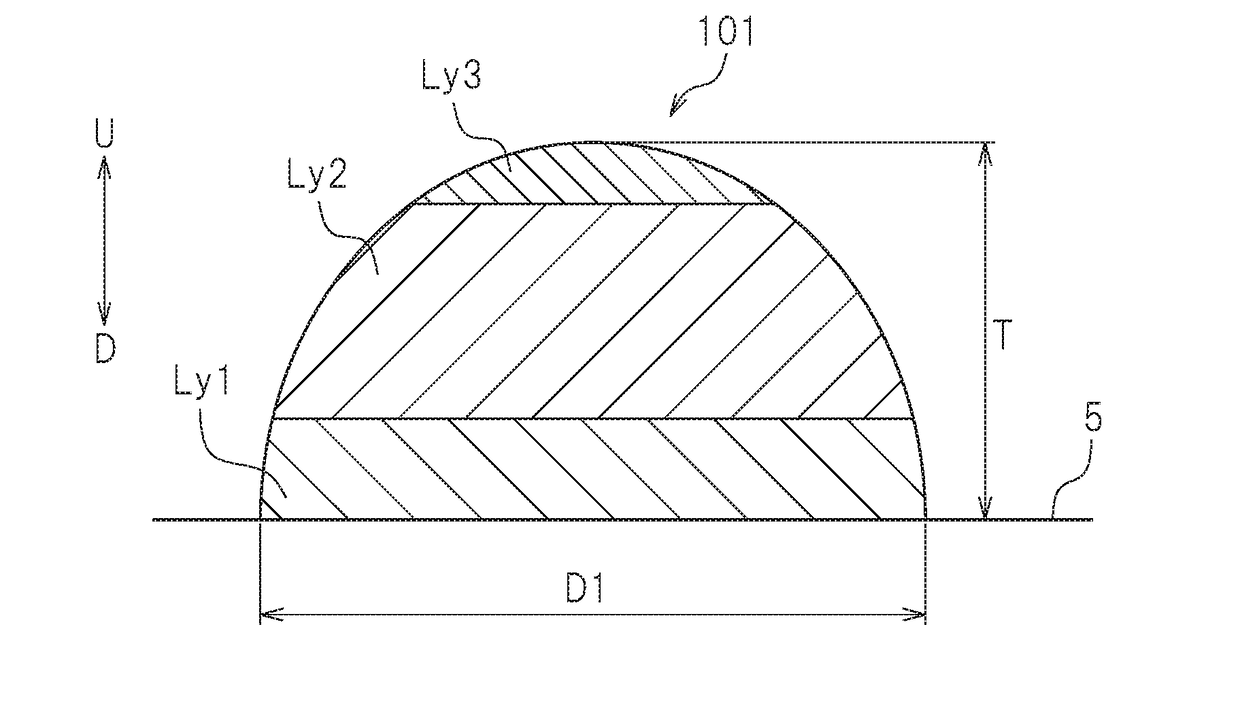

[0072]FIG. 9 is a cross-sectional view of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com