Helmet insert

a technology for inserts and helmets, applied in helmets, sports equipment, helmets, etc., can solve the problems of limited deformation distance, increased head injury risk, increased propensity for overheating, etc., and achieves the effect of widening the performance window of inserts and effective protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

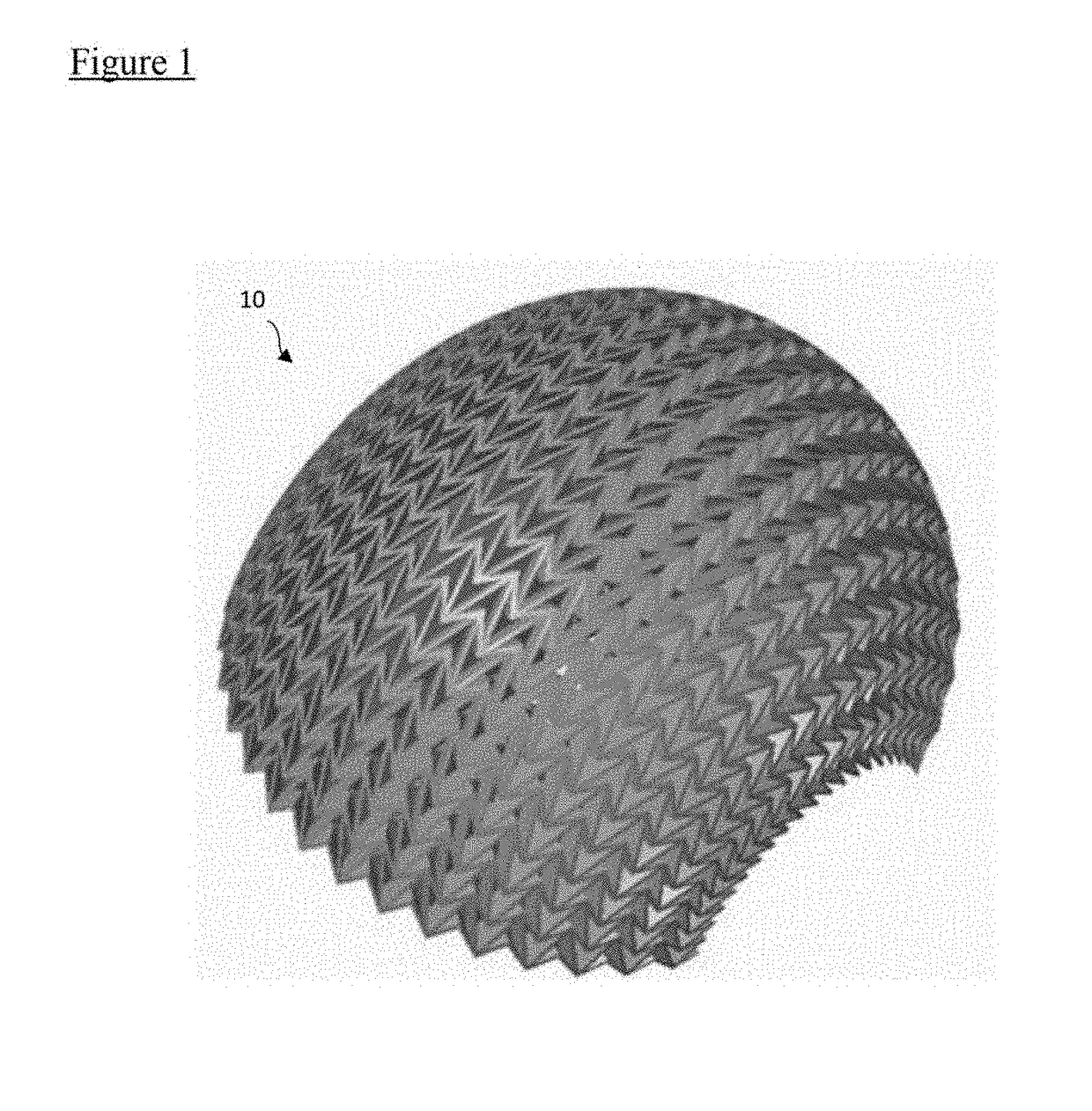

[0045]Referring firstly to FIG. 1, an insert for a helmet is indicated generally at 10. The insert 10 is intended to be fitted within a substantially hard outer shell of a helmet. A soft liner is intended to be inserted into the interior of the insert 10 to sit between the insert 10 and the wearer's head in use. The insert 10 comprises a plurality of layers (not labelled in FIG. 1 in the interests of clarity). The insert 10 has a curved outer surface adapted to abut an inner surface of a helmet outer layer in use.

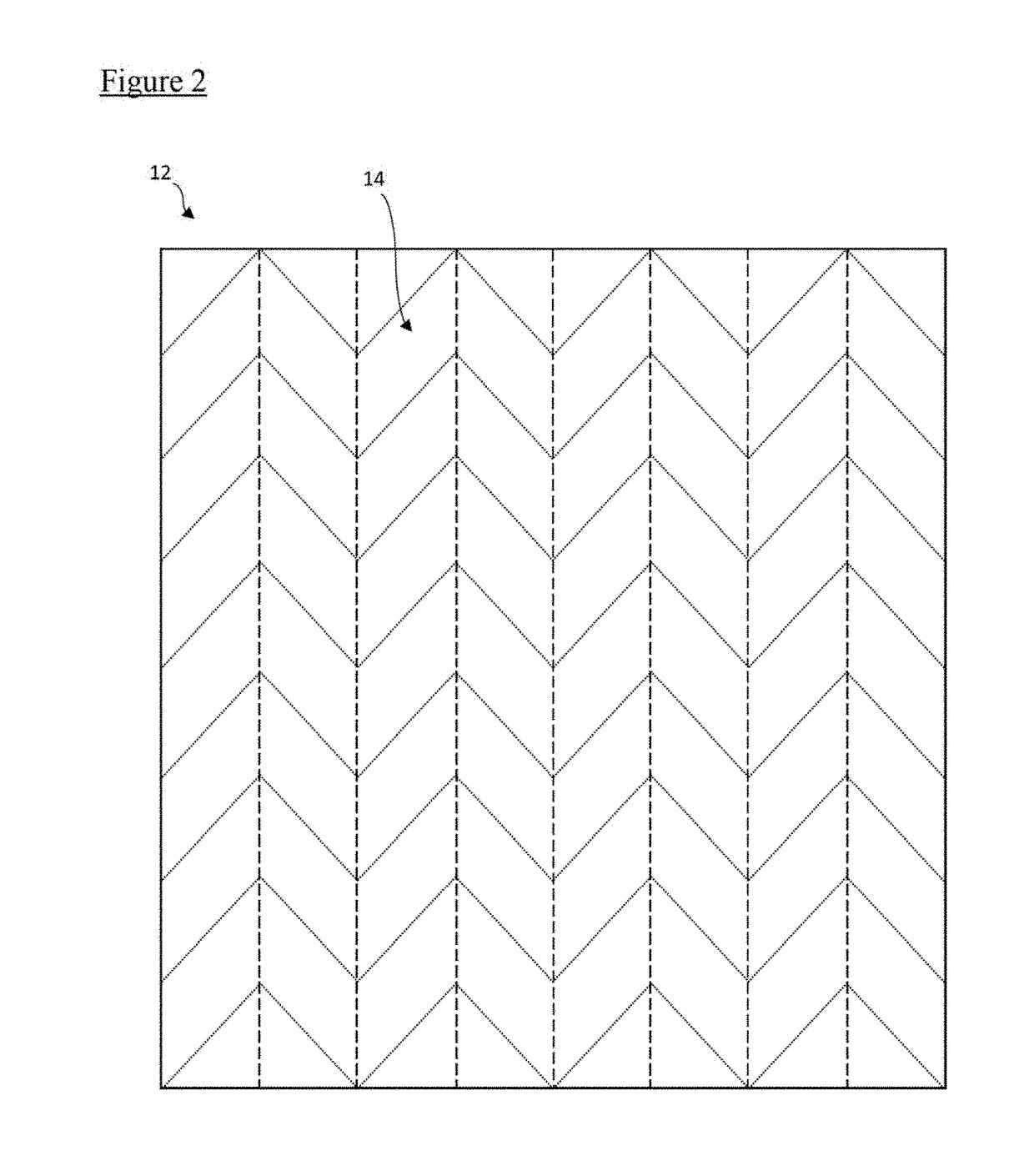

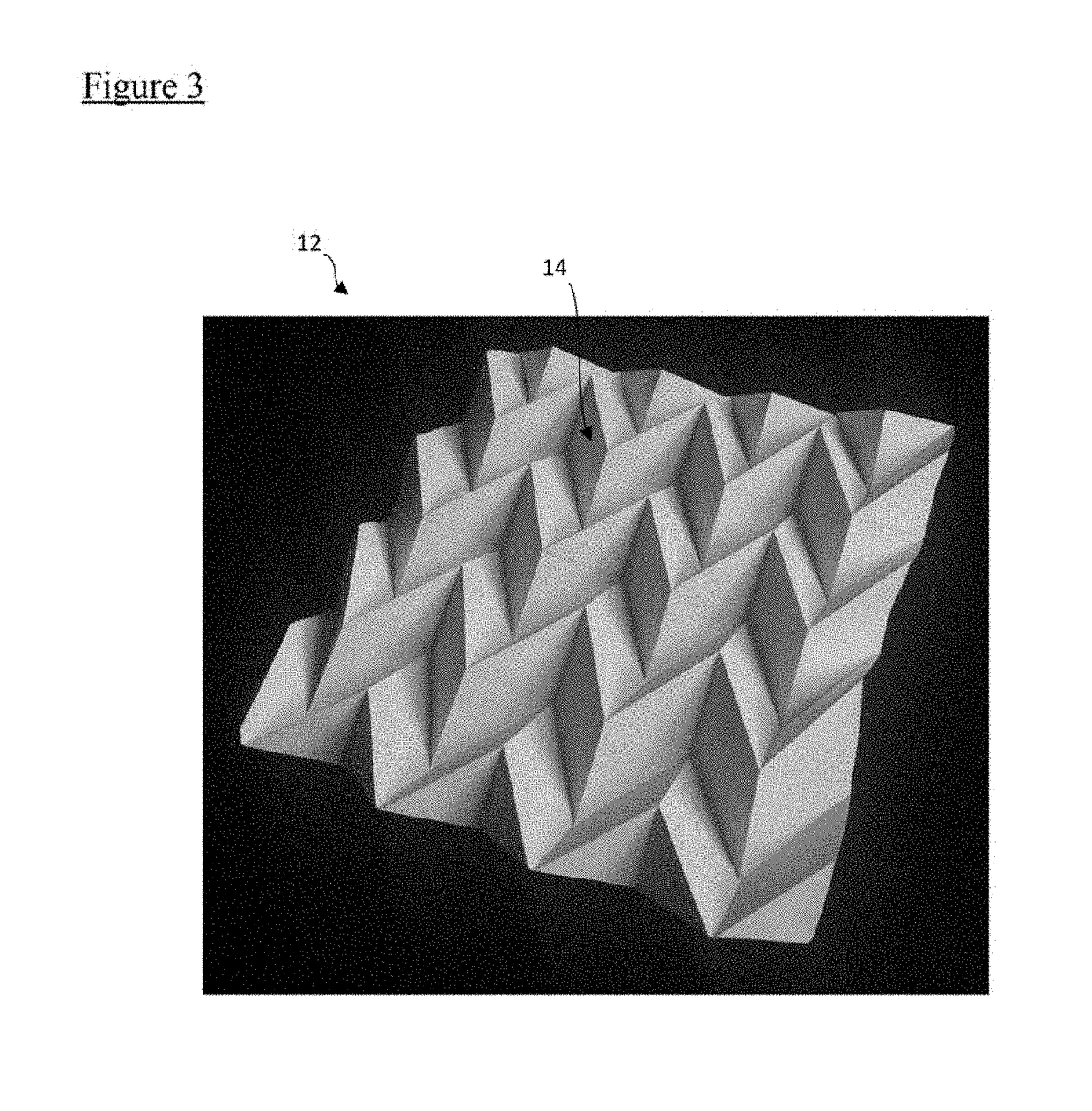

[0046]The layers are described below with reference to a single exemplary layer 12. The exemplary layer consists of a sheet of material folded to produce a three-dimensional structure. The exemplary layer 12 has a planar overall geometry, that is, it is substantially flat. However, it will be understood that the layers used in the helmet have a curved overall geometry. The features of the layers of the helmet insert 10 are small relative to the radius of curvature of the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com