Energy-absorbing 3D printing material, preparation method and energy-absorbing device

A 3D printing and energy-absorbing device technology, applied in the direction of additive processing, etc., can solve the problems of unsatisfactory energy-absorbing performance, memory performance and lightweight performance performance, achieve good synergy, reduce property loss, and excellent shape The effect of memory function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

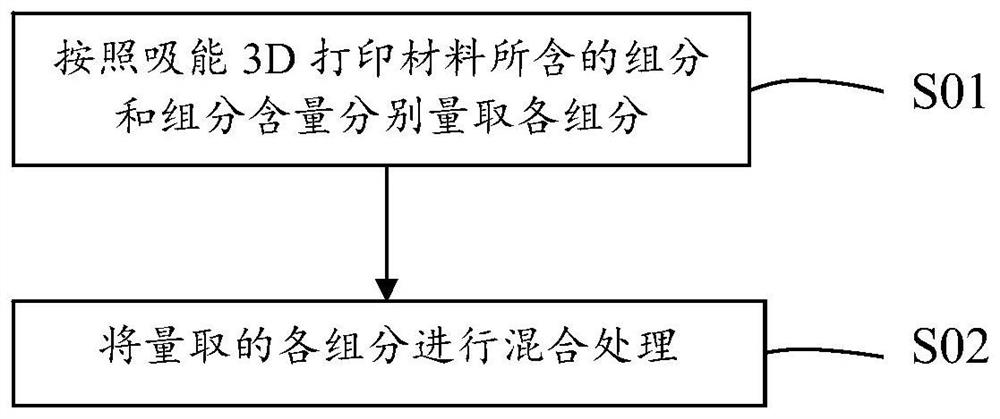

[0032] Accordingly, based on the energy-absorbing 3D printing material described above, embodiments of the present invention further provide a method of preparing the energy-absorbing 3D printing material. The preparation method of the energy-absorbing 3D printing material is as follows Figure 1 as shown, which includes the following steps:

[0033] S01: According to the components and component content contained in the energy-absorbing 3D printing material, each component is taken separately;

[0034] S02: The measured components are mixed.

[0035] Specifically, the energy-absorbing 3D printing material in step S01 as described above the energy-absorbing 3D printing material,

[0036] Therefore, the energy-absorbing 3D printing material contains components and components content of the energy-absorbing 3D printing material and the corresponding content above, in order to save space, the components and components of the energy-absorbing 3D printing material are no longer describe...

Embodiment 1

[0047] The present embodiment provides an energy-absorbing 3D printing material and a preparation method thereof.

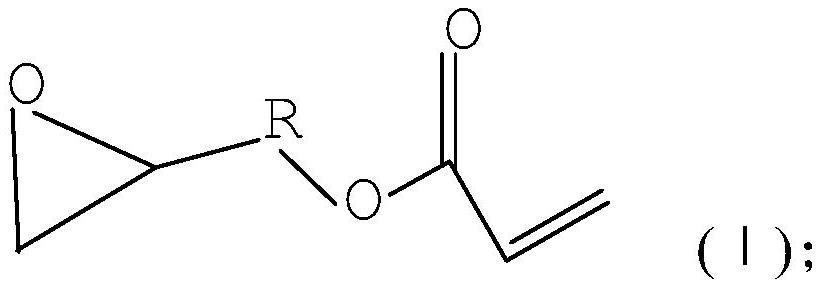

[0048] The energy-absorbing 3D printing material comprises: tert-butyl methacrylate 80 parts, aliphatic epoxy acrylate 20 parts, photoinitiator TPO 2 parts. Wherein, aliphatic epoxy acrylate is the aliphatic epoxy acrylate shown in formula I of the molecular structure above.

[0049] The preparation method of the energy-absorbing 3D printing material comprises the following steps:

[0050] The tert-butyl methacrylate 80 parts, aliphatic epoxy acrylate 20 parts at room temperature mixed, stirred for 60 minutes, so that to a transparent uniform liquid; in the above obtained solution, add photoinitiator TPO 2 parts, mechanical stirring 30min, to obtain 3D printing photosensitive resin, but also for energy absorption 3D printing materials.

Embodiment 2

[0052] The present embodiment provides an energy-absorbing 3D printing material and a preparation method thereof.

[0053] The energy-absorbing 3D printing material comprises: tert-butyl methacrylate 85 parts, aliphatic epoxy acrylate 15 parts, photoinitiator TPO 2 parts. Wherein, aliphatic epoxy acrylate is the aliphatic epoxy acrylate shown in formula I of the molecular structure above.

[0054] The preparation method of the energy-absorbing 3D printing material comprises the following steps:

[0055]The tert-butyl methacrylate 85 parts, aliphatic epoxy acrylate 15 parts at room temperature mixed, stirred for 60 minutes, so that to a transparent uniform liquid; in the above obtained solution, add photoinitiator TPO 2 parts, mechanical stirring 30min, to obtain 3D printing photosensitive resin, but also for energy absorption 3D printing materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com