A kind of preparation method of filling density gradient controllable foam metal thin-walled composite pipe

A metal foam and filling density technology, which is applied in the field of material forming, can solve the problems of complicated metal foam material preparation principles, difficulty in obtaining products with stable performance, and practical preparation difficulties, so as to achieve stable deformation modes, controllable density gradients, and improved use. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

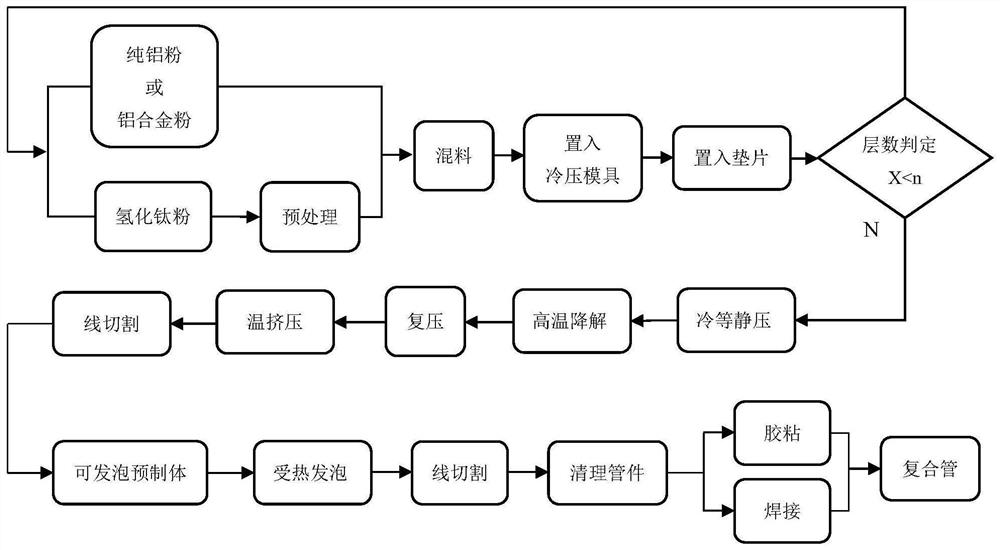

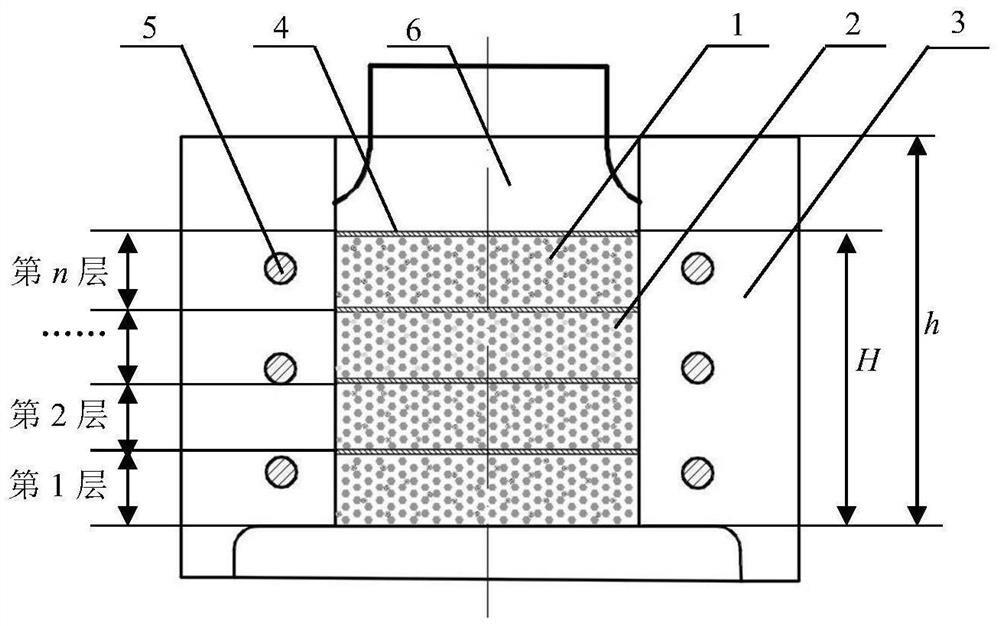

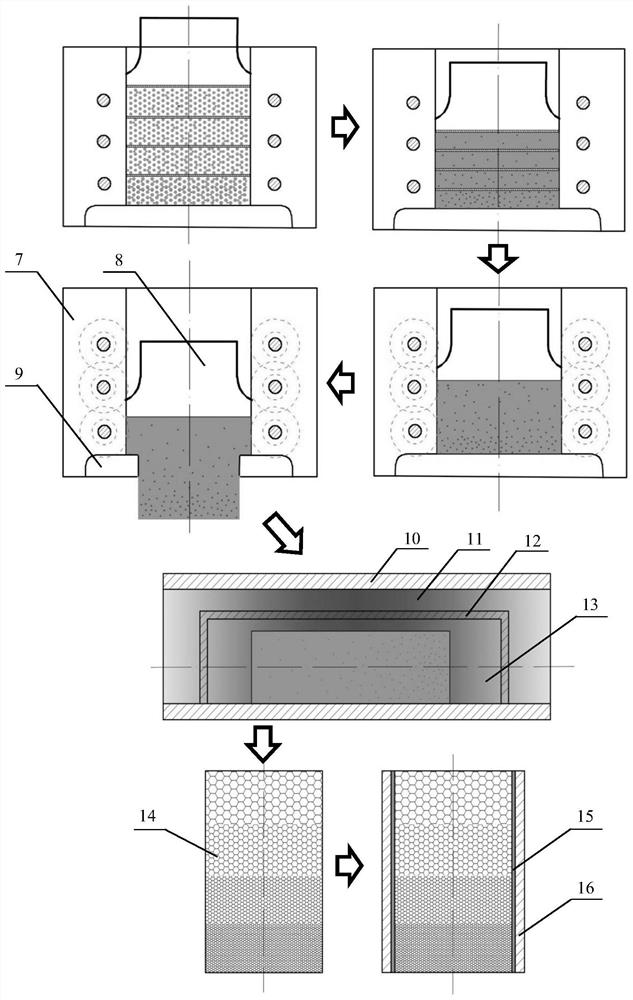

[0044] Taking the preparation of a composite circular tube filled with five-layer cell density gradient controllable metal foam as an example, and using Figure 4 The gradient change form of filled metal foam with medium pore density gradually decreasing along the axial direction is the design target. The relative density of the five layers of metal foam from high to low is designed to be 0.24, 0.2, 0.16, 0.12 and 0.08 in sequence, and each layer of metal foam cylinder occupies The same 7070cm 3 volume.

[0045] The preparation process of this embodiment is as follows:

[0046] The first step, gradient form selection:

[0047] According to the target needs, from Figure 4 Among the given three ways of pore density gradient change, the gradient form 17 in which the relative density of foam metal gradually increases or decreases from one end to the other end is selected as the target gradient form of this example.

[0048] The second step, mixing:

[0049] according to fig...

Embodiment 2

[0063] Take the preparation of a composite rectangular tube filled with five-layer cell density gradient metal foam as an example, such as Figure 4 As shown, the density gradient change of filled metal foam is designed to be high relative density along the middle and low relative density at both ends, and the relative density is designed to be 0.3, 0.22 and 0.14 in sequence from the middle to both ends, and each layer of metal foam cuboid occupies 1500cm 3 volume of.

[0064] The preparation process of this embodiment is as follows:

[0065] first step,

[0066] Gradient form selection:

[0067] According to the target needs, from Figure 4 Among the three kinds of pore density gradient change methods, the gradient form 18 with the highest relative density of the foam metal middle layer and gradually decreasing relative density to both ends is selected as the target gradient form of this example.

[0068] The second step, mixing:

[0069] according to figure 1 According...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com