Continuous dyeing plant for warp threads comprising an oxidation apparatus having variable and recoverable capacity

a technology of oxidation apparatus and dyeing plant, which is applied in the direction of textile treatment, textile treatment rollers, textiles and paper, etc., can solve problems such as relative deterioration, and achieve the effect of reducing the amount of thread

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

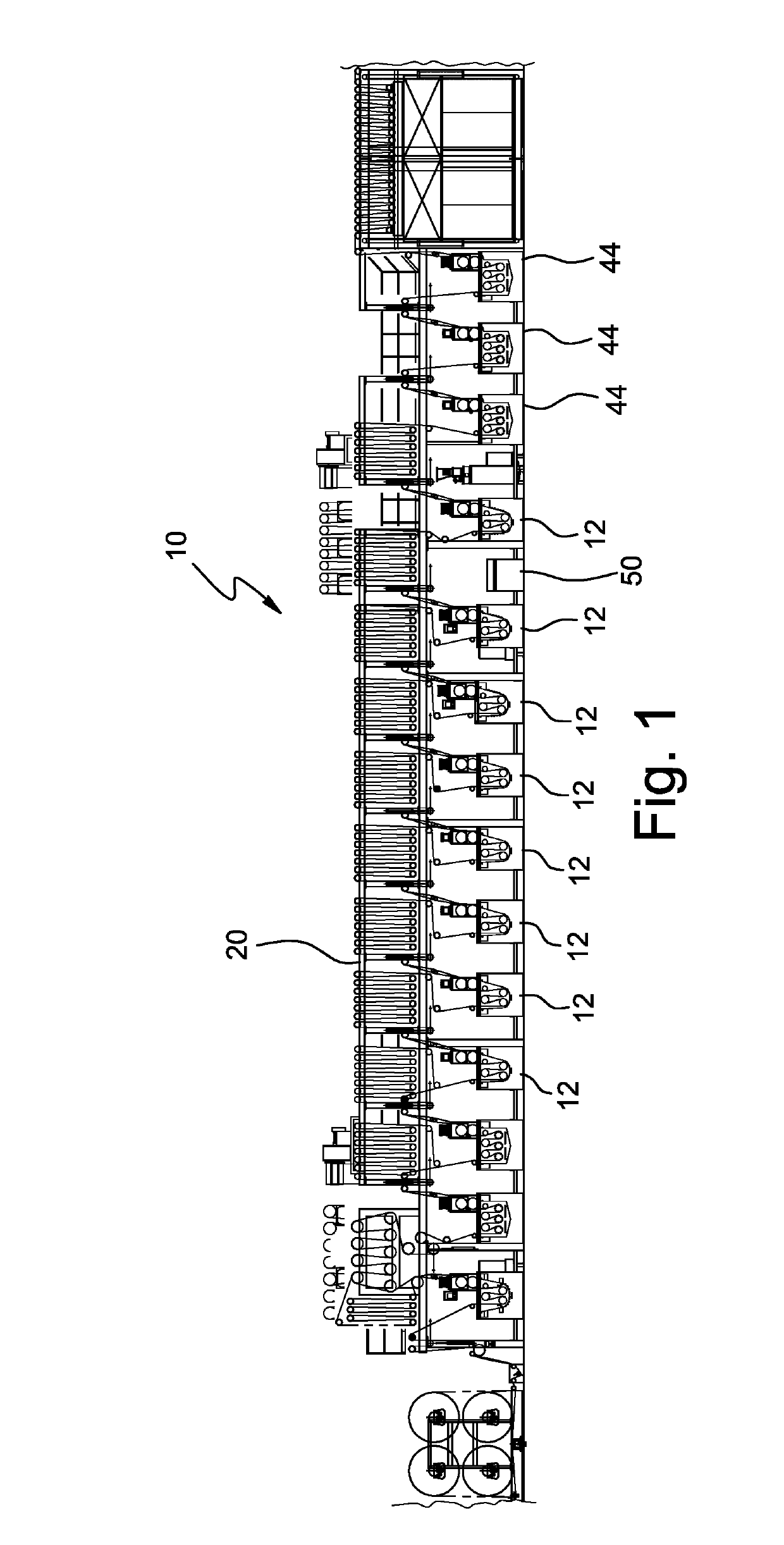

[0025]With reference in particular to FIG. 1, a generic continuous dyeing plant for threads is shown, wholly indicated with reference numeral 10. In particular, the plant 10 is a plant configured to operate according to the open width dyeing system.

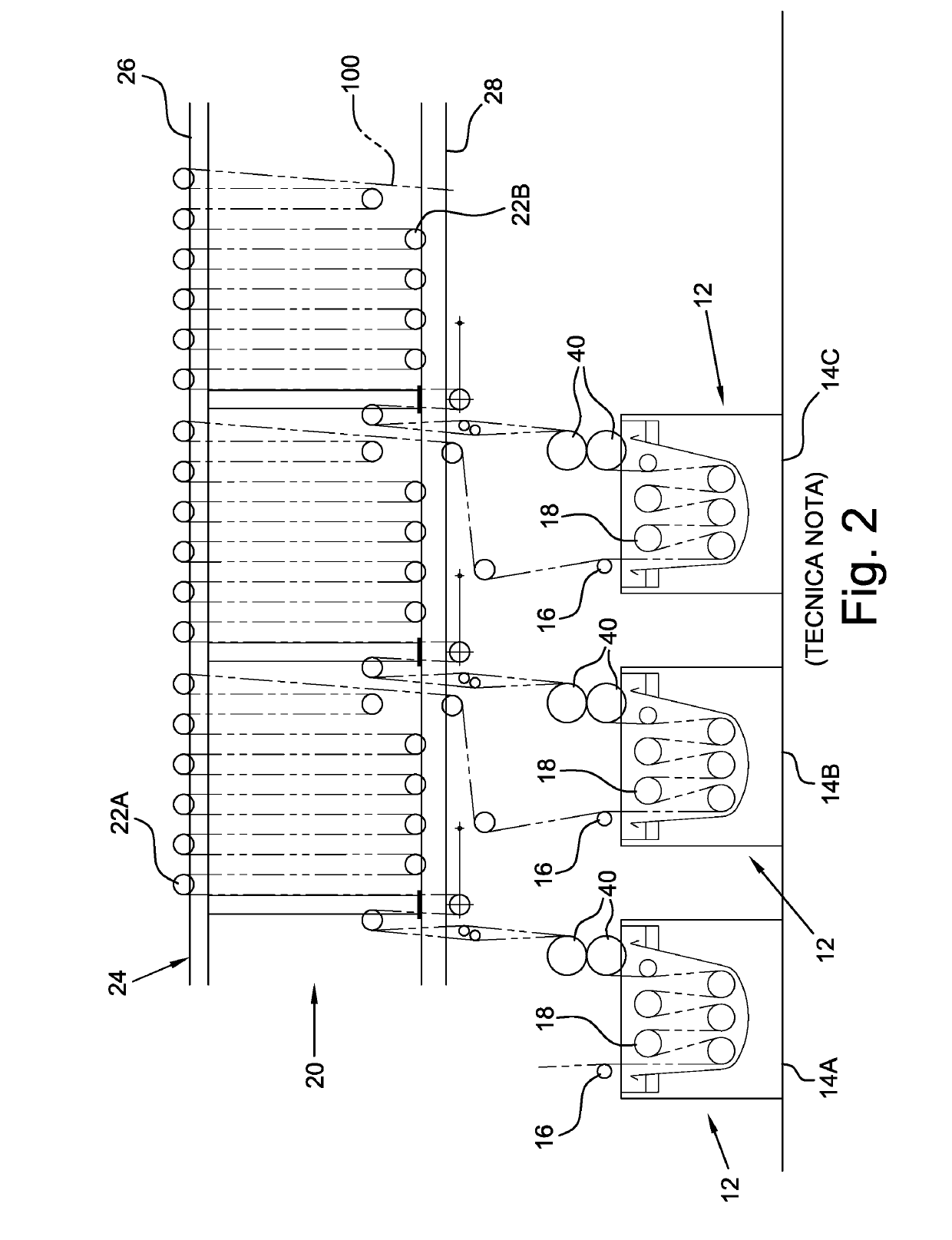

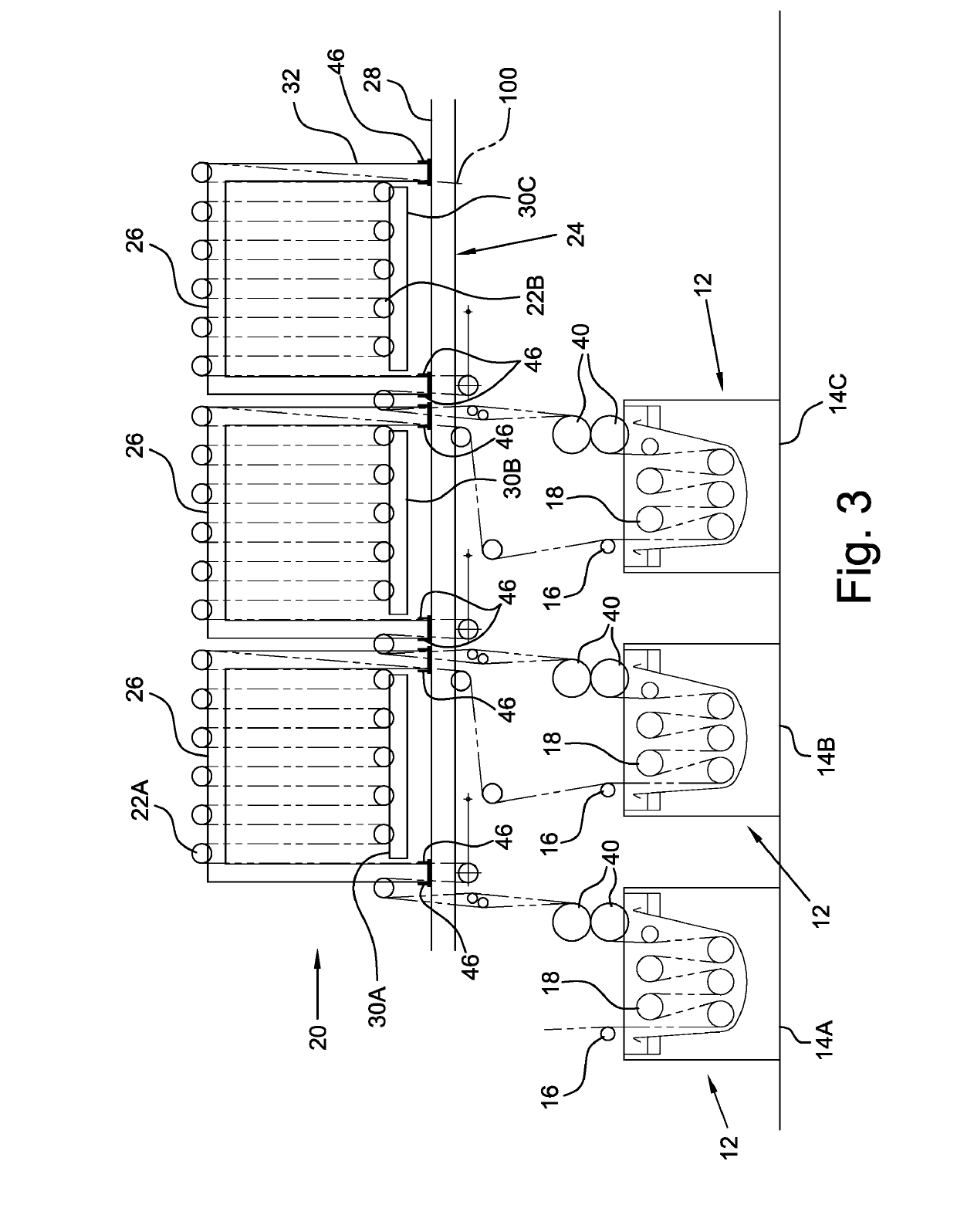

[0026]The plant 10 comprises a plurality of dyeing / squeezing groups 12 arranged in line, each of which is provided with a respective impregnation or dyeing tank 14A, 14B, 14C in which a warp thread 100, which advances from left to right with reference to the representation of the plant of FIG. 1, is immersed in a dyeing bath containing a dyeing substance. The dyeing bath can, for example, comprises an alkaline solution of indigo dye.

[0027]As shown in FIGS. 2-4, the warp thread 100 arrives in each tank 14A, 14B, 14C passing over a respective guide roller 16 and then immerses in the tank 14A, 14B, 14C itself winding onto a plurality of return rollers 18. At the exit of each tank 14A, 14B, 14C the warp thread 100 undergoes a squeezing passin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com