Gas diverter for well and reservoir stimulation

a technology for reservoirs and gas diverters, which is applied in the direction of fluid removal, borehole/well accessories, chemistry apparatuses and processes, etc., can solve the problems of increasing the degree of fracturing within the low stress downhole formation, affecting the health and productivity of wells, and reducing the extent and/or degree of fracturing within the high stress formation, so as to prevent well bashing and/or well interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

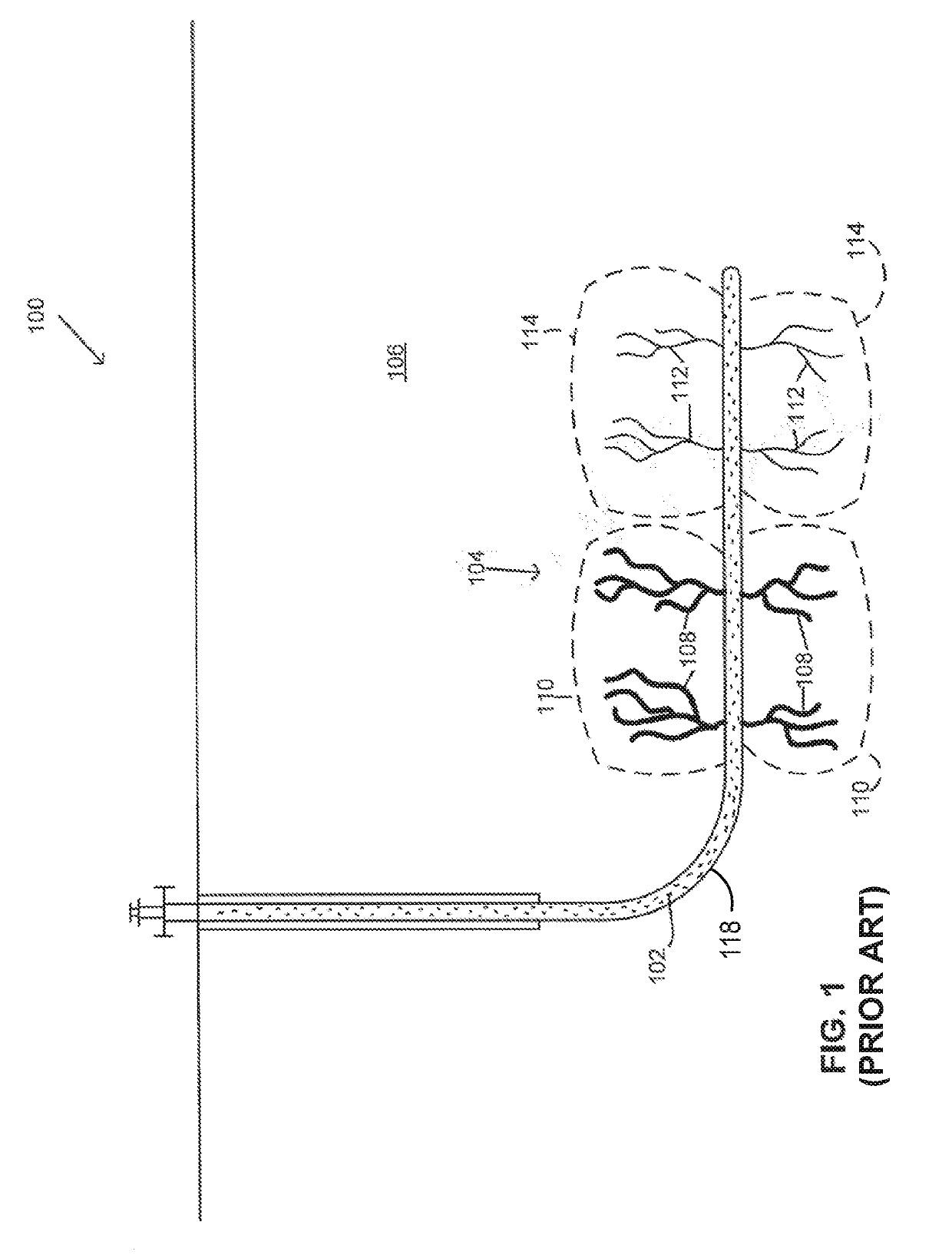

[0177]FIG. 1 depicts a side view of a horizontal drilled well 100 treated according to a method of the prior art utilizing a fracturing liquid 102 to produce multiple fractures 104 within a subterranean formation 106. The multiple fractures 104 produced by the pressurized liquid 102 can vary in size. Typically, low stress zones 110 contain larger fractures and / or pore volumes 108 than high stress zones 114. During stimulation, re-stimulation or re-fracturing the fracturing liquid 102 typically tends to concentrate in the larger fractures and / or larger pore volumes 108 of low stress zones 110. These low stress zones 110 tend to be zones of hydrocarbon depletion, lower pore pressure, higher permeability, or a combination thereof. Permeability of the reservoir can, in part, depend on the extensiveness and interconnectivity of the fractures and / or pores. Moreover, hydrocarbon flow typically depends on the extensiveness and / or interconnectivity of the fractures and / or pores that create p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com