Carpet compositions having laminated film backings and methods for making same

a technology of laminated film backing and carpet composition, which is applied in the field of carpet compositions and carpet products, can solve the problems of large production lines, difficult recycling, and high cost of manufacturing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

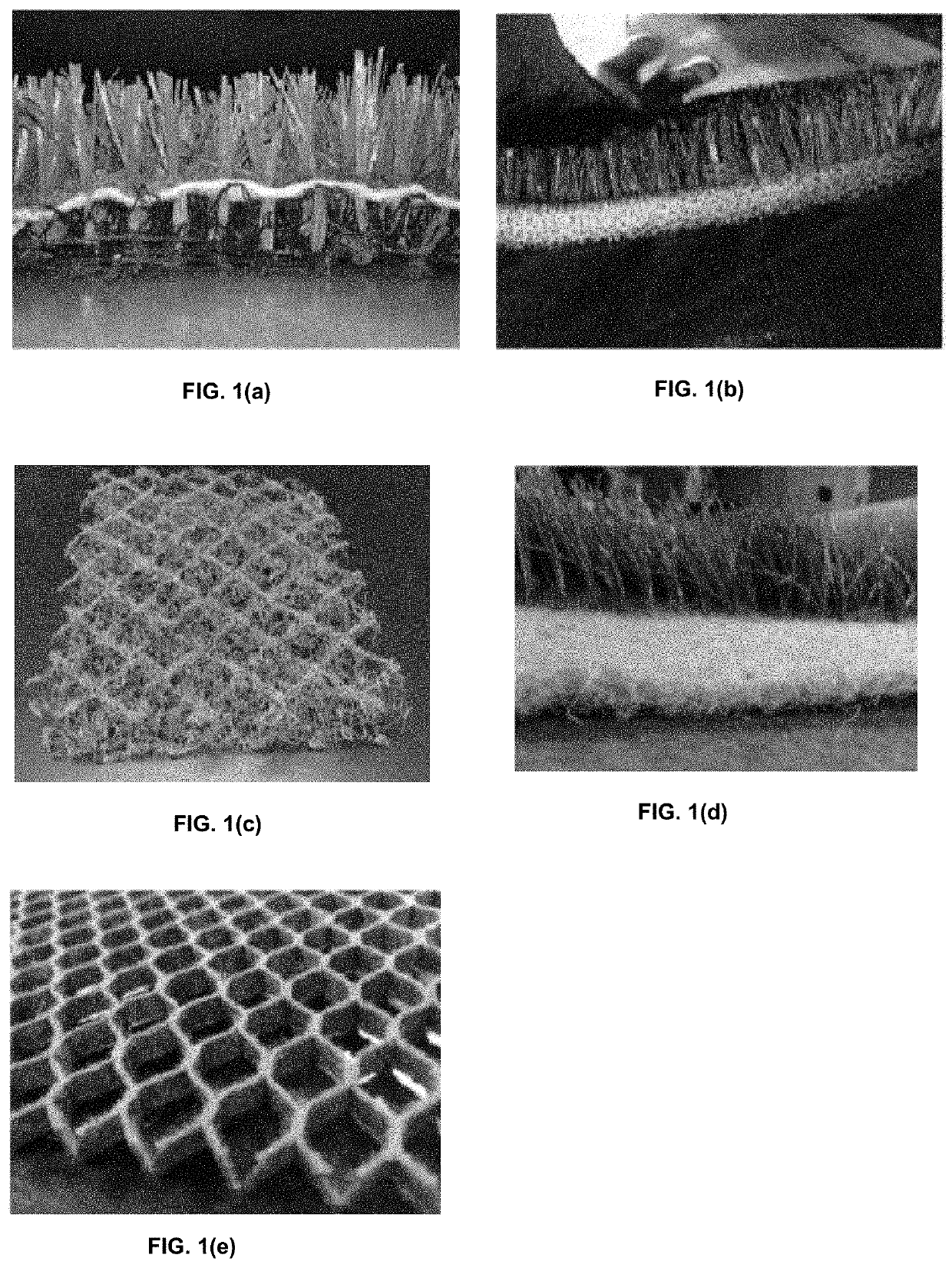

Image

Examples

example 1

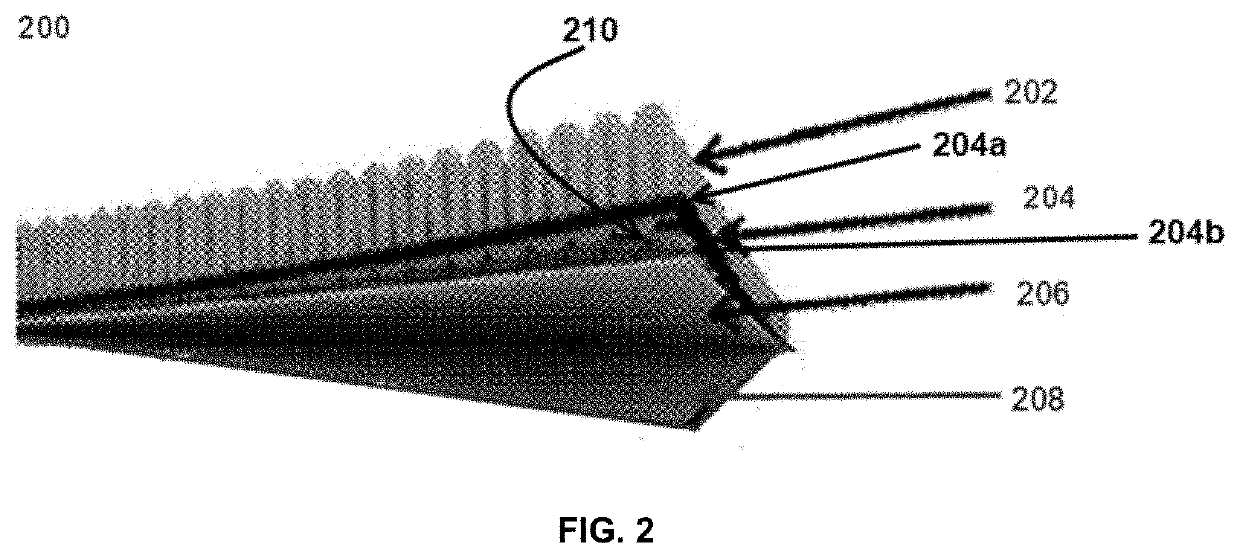

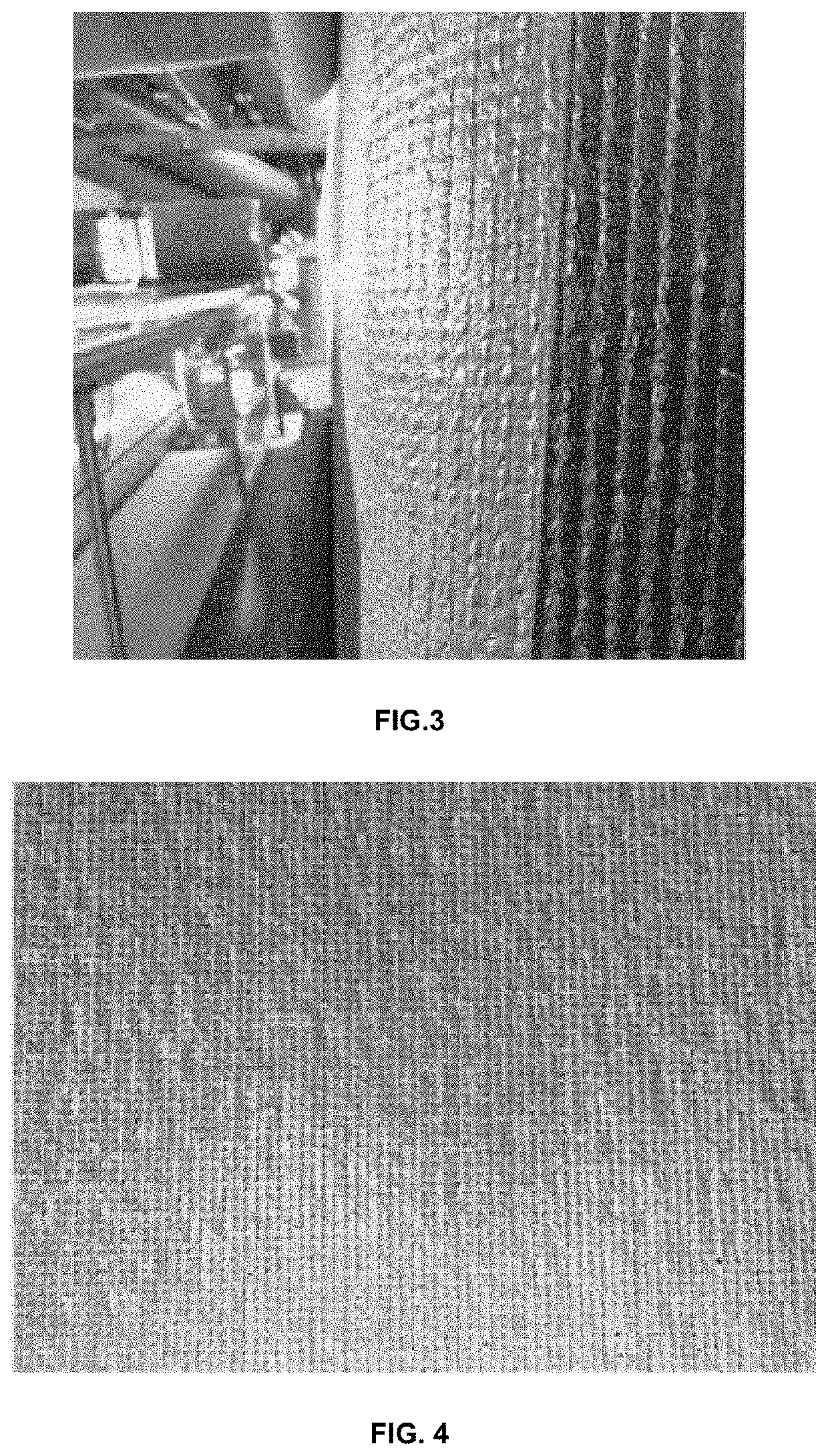

[0153]The inventive turf composition was prepared according to the aspects described above. In this example, the inventive film used for lamination was an engineered film having a thickness of 5 mil or 0.005 inch and comprised of three layers with the outer layers comprising polyethylene and the inner layer comprising polypropylene. The backstitches were preheated using IR radiation immediately prior to lamination. It is understood that other types of preheat can be also utilized. The lamination was performed at 5-10 FPM, preheat temperature in a range from about 200° F. to about 260° F., lamination temperature of about 346° F., pressure of about 100 psi, and a lamination gap of 10-20 thousandth of inch (10-20 mils). The performance of the inventive carpet composition having a film laminated to the backstitches was compared to a number of the carpet compositions having their backstitches locked in place by other known in the art methods. The carpet compositions tested and compared t...

example 2

[0154]The inventive carpet compositions having the backstitches locked in place by a film lamination were made using various types of turfs. The tested turfs comprised a polypropylene woven primary backing, slit tape or monofilament yarn tufted into the primary backing to provide a turf having various face densities. Fresh Rye-polypropylene and Fresh-Rey polyethylene samples refer to the turf samples having a polymer type of the relaxed thatch yarn that makes turf appearance more similar to natural grass. Performance data for such compositions was measured. The comparative results shown in Table 2 represent an average of multiple (minimum 5) measurements. Specifically, Table 2 shows tuft and slip bind strengths, along with grab / tear and dimensional stability properties for various inventive carpet compositions having their backstitches locked in place by laminating a film.

TABLE 2Performance data of the carpet compositions havinga laminated film on different turf types.FreshFreshFabr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com