Static wet abrasive blasting system utilizing automated valves to simplify setup and operational functions

a technology of wet abrasive blasting and automated valves, which is applied in the field of cleaning devices, can solve the problems of erratic behavior of the wet abrasive blasting system, damage to the substrate, excessive surface roughness, etc., and achieve the effect of reducing the amount of airborne dust and minimizing surface damag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

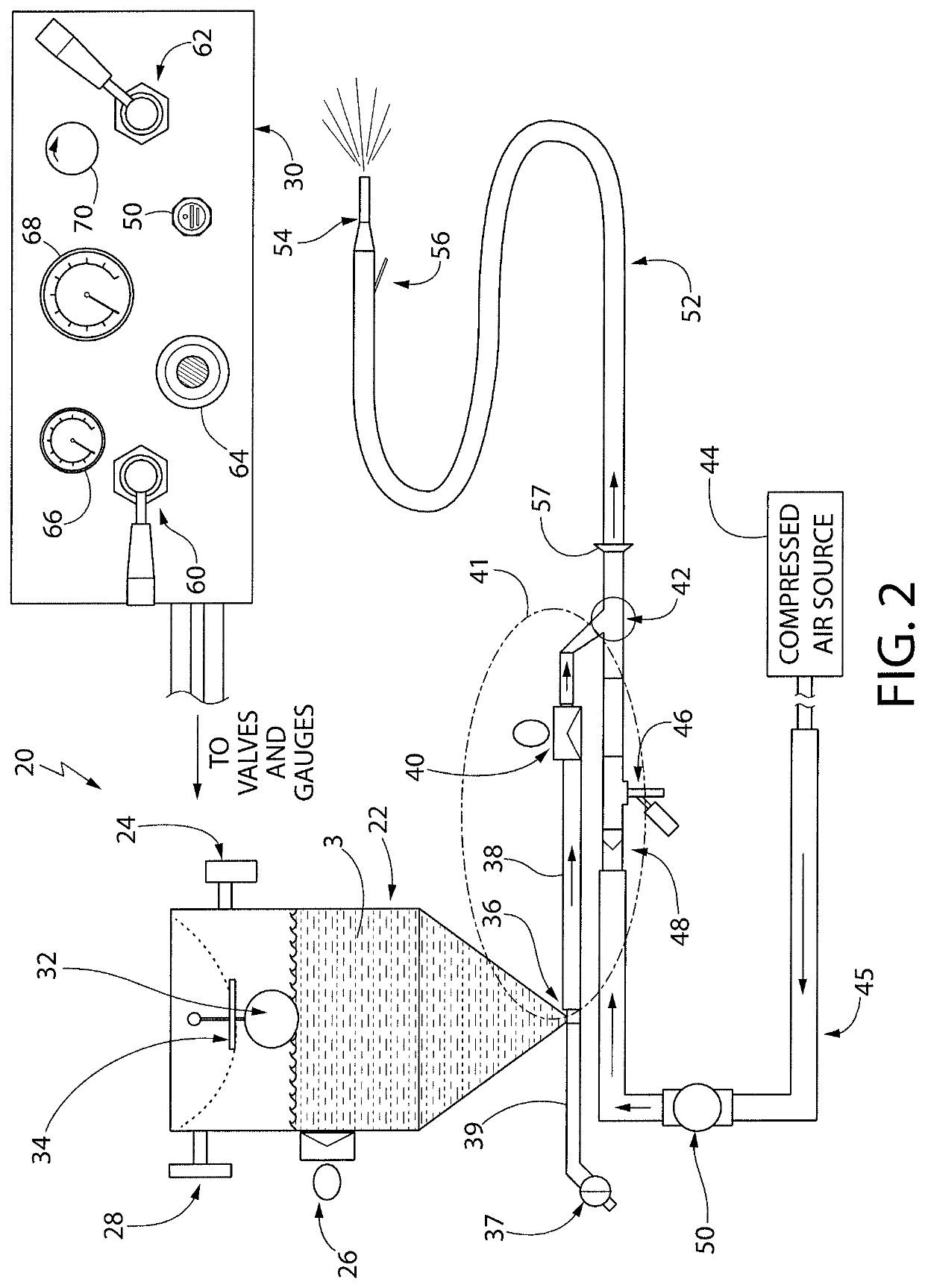

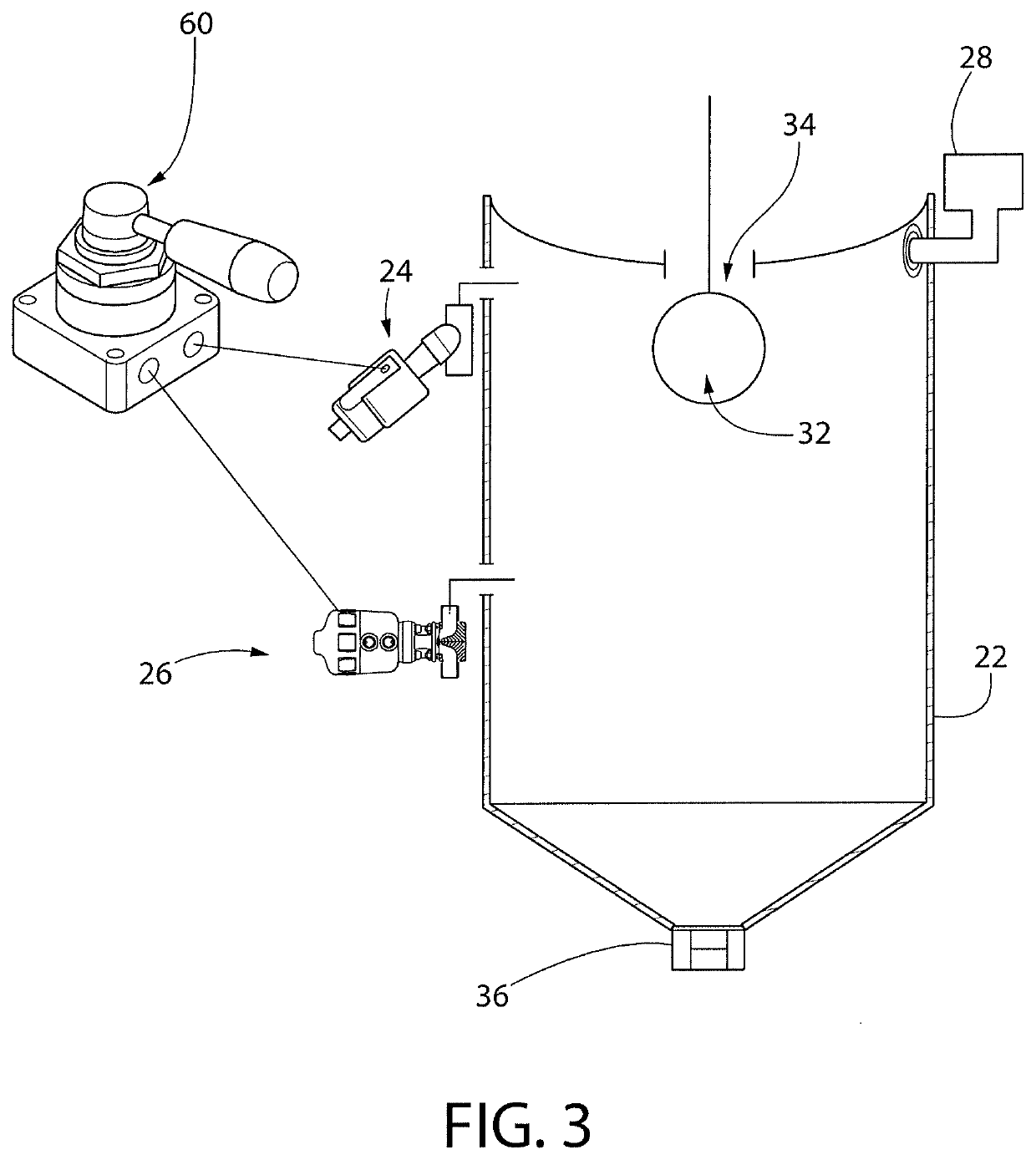

[0017]Referring now to the figures, wherein like reference numerals represent like parts throughout the several views, exemplary embodiments of the present disclosure will be described in detail. Throughout this description, various components may be identified having specific values, these values are provided as exemplary embodiments and should not be limiting of various concepts of the present invention as many comparable sizes and / or values may be implemented.

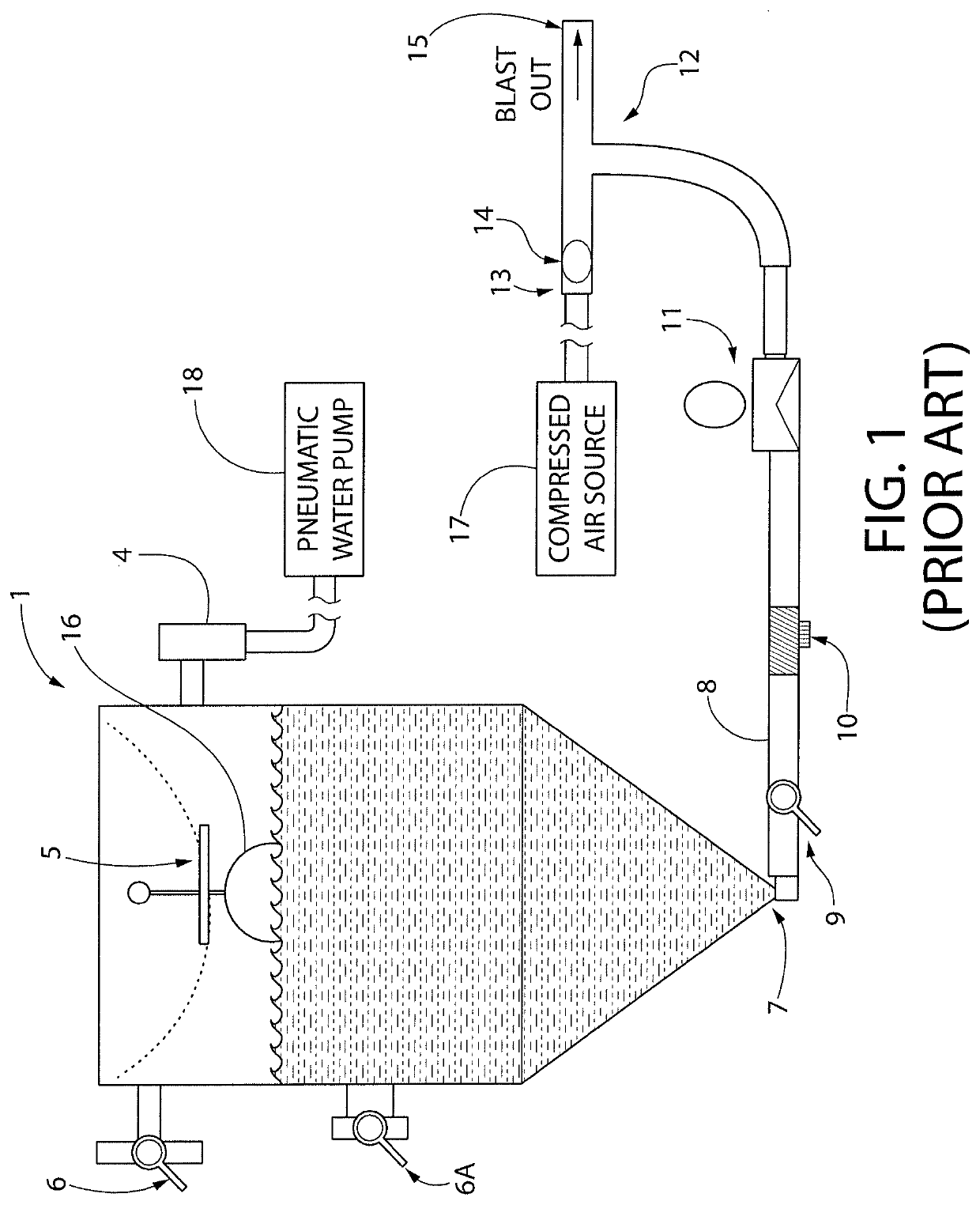

[0018]As will be discussed in detail later, the invention of the present application is directed toward wet abrasive blasting systems used for cleaning, preparing surfaces, removing coatings, and other abrasive blasting applications. Embodiments of the wet abrasive basting system comprise of a series of pilot controlled pneumatics automating the basic and advanced functions in setting up, operating, and shutting down the system. The floating bung and vent assembly allow for the air to escape the pot allowing for the pot to p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| liquid level | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com