Expander for expanding metal pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

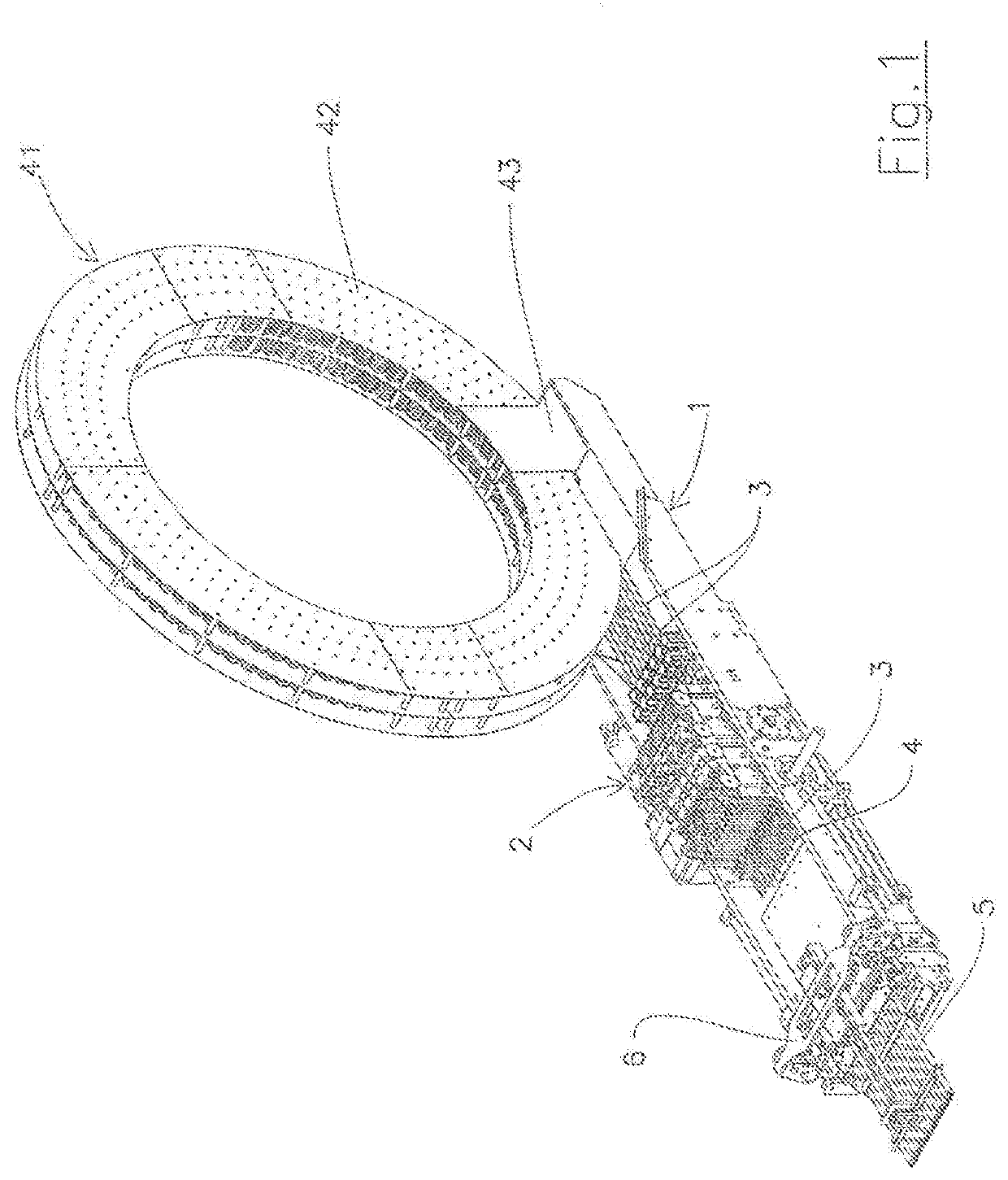

[0032]The expander shown as a whole in FIG. 1 comprises a supporting frame 1 which supports a moving assembly 2 of flexible rods 3 from which expander mandrels 4 extend, which can be inserted into the axial cavities of the respective pipes 5 the transversal expansion of which is desired. The aforesaid pipes 5 are kept in position aligned with the expander mandrels 4 by a support 6 fixed to a front end of the frame 1.

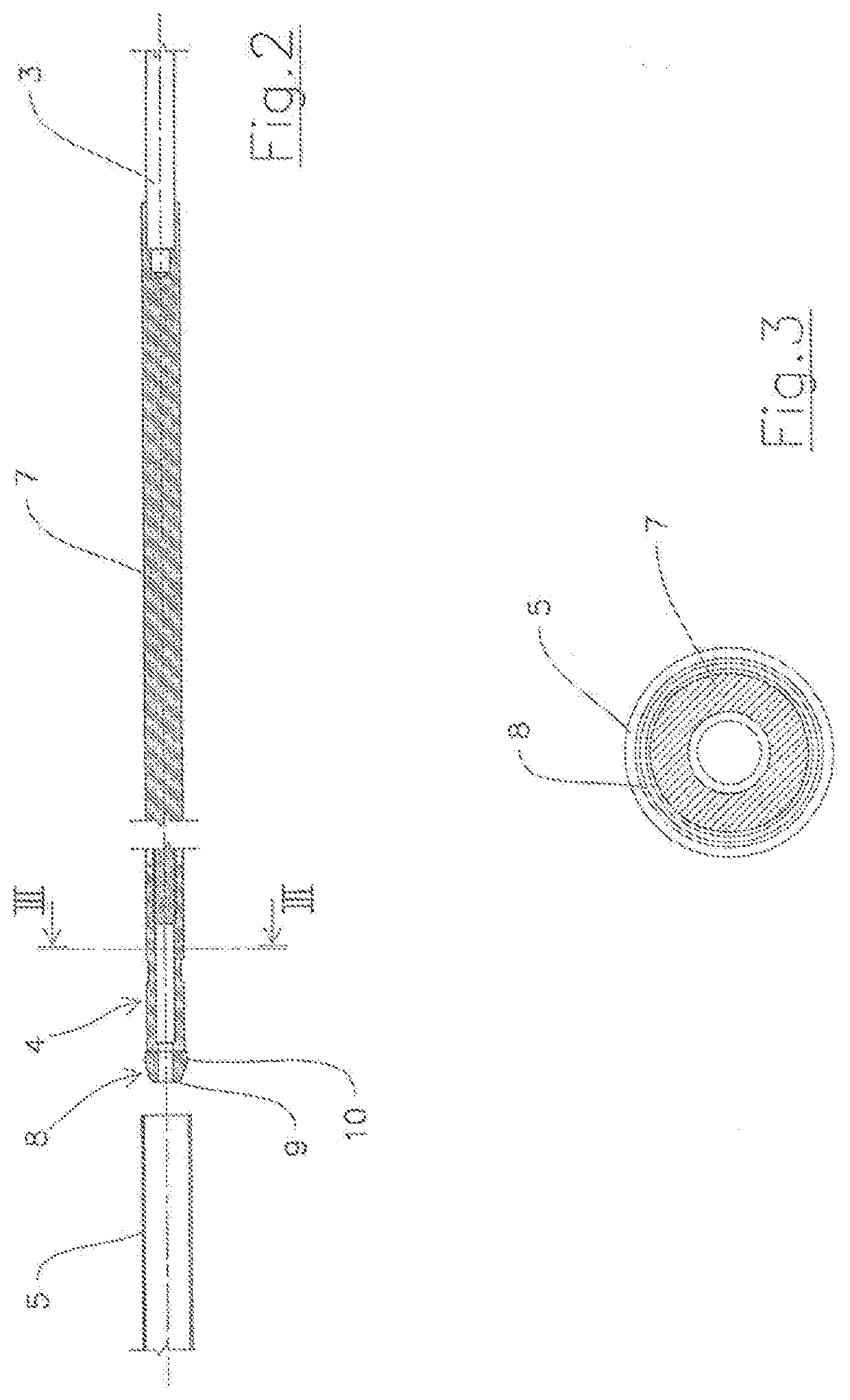

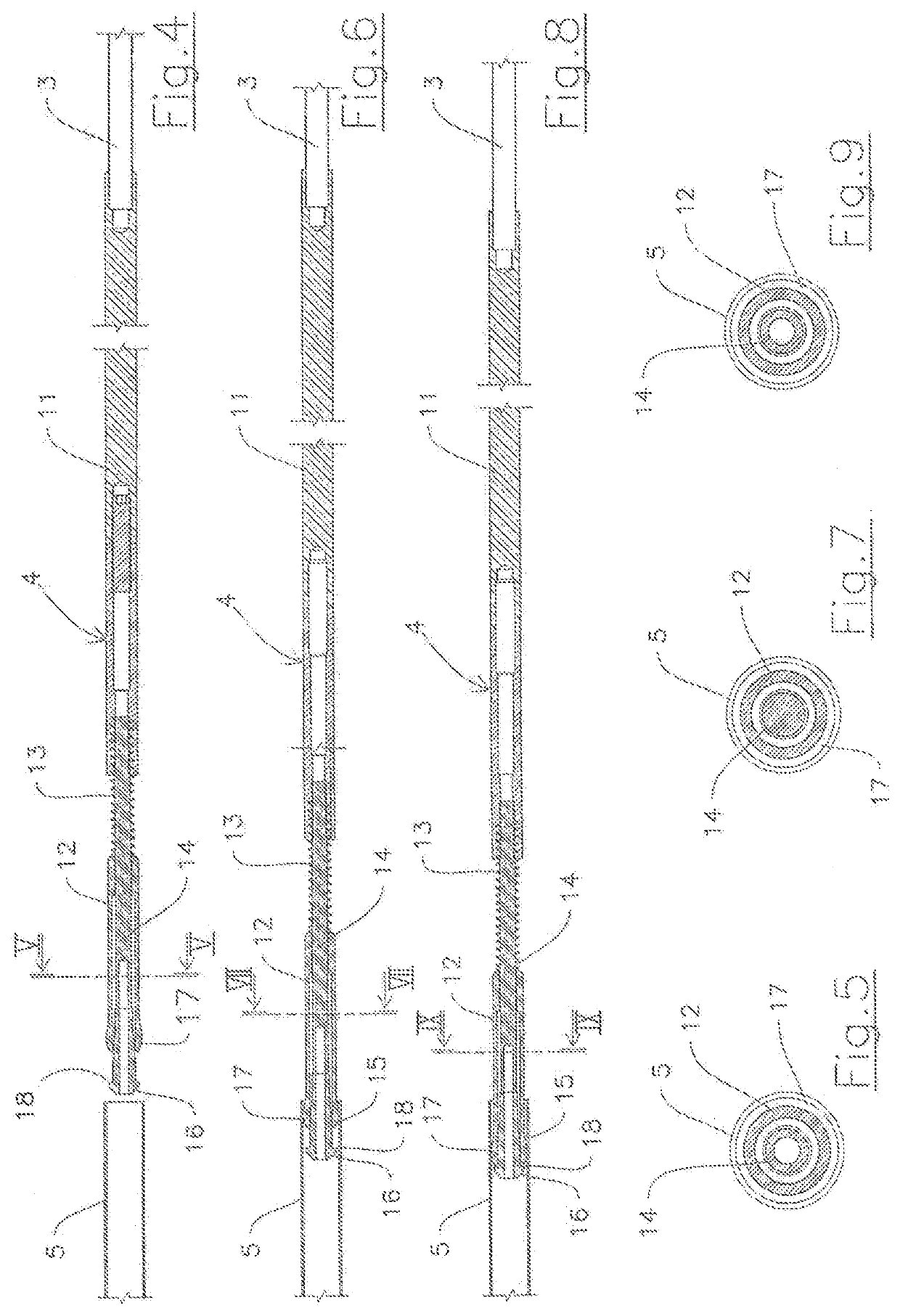

[0033]The expander mandrels 4 can be of two types, shown in FIGS. 2-3 and 4-9, respectively.

[0034]The expander mandrel in FIGS. 2-3 is of the push type, i.e. is able to operate the transverse expansion of pipe 5 by means of axial pushing. For such a purpose, the mandrel comprises a rigid body 7 with a rear end fixed to the front end of a respective flexible rod 3 and a front end ending in a substantially truncated-cone-shaped expansion head 8 with a terminal front 9 of diameter smaller than that of the inner cavity of pipe 5 and a section 10 behind of a larger diameter t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap