Method for etching recessed structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

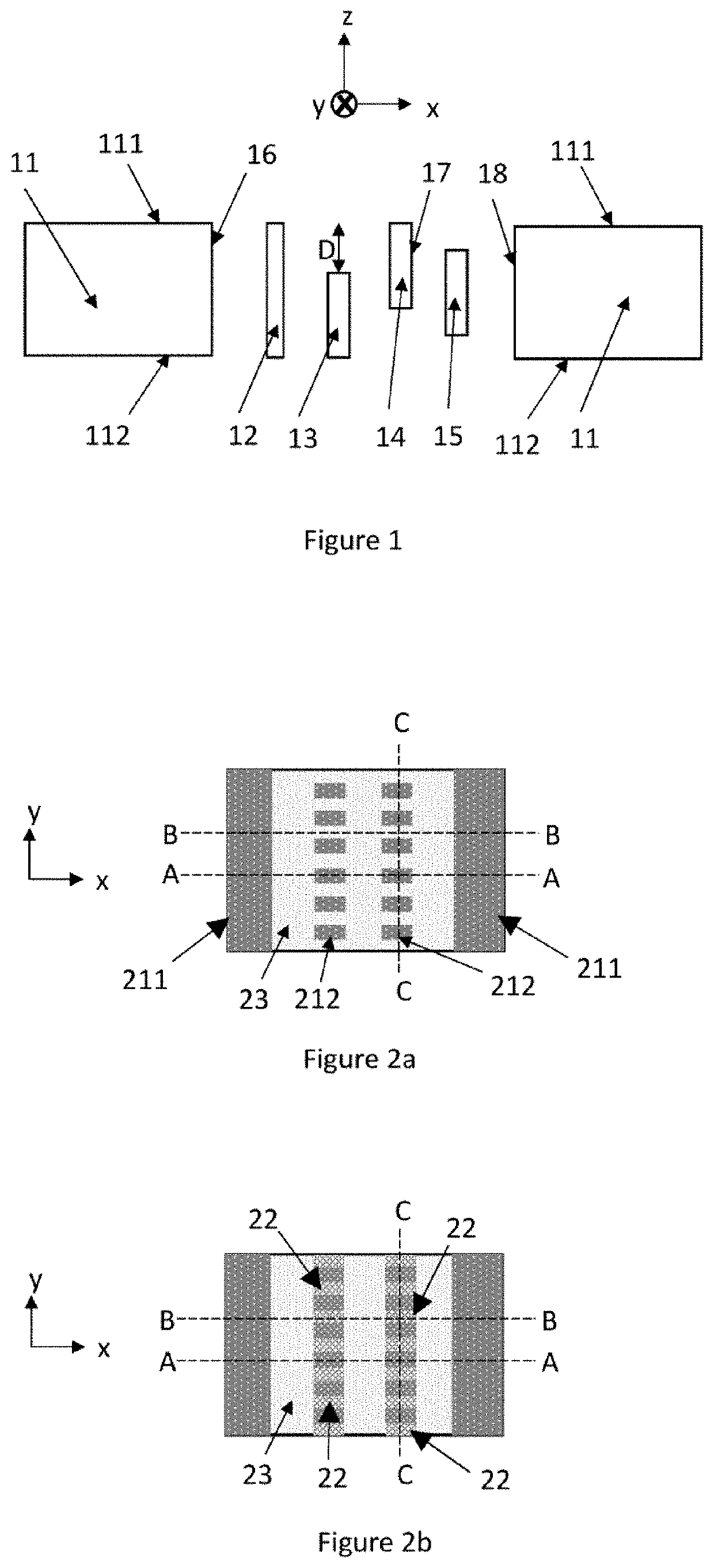

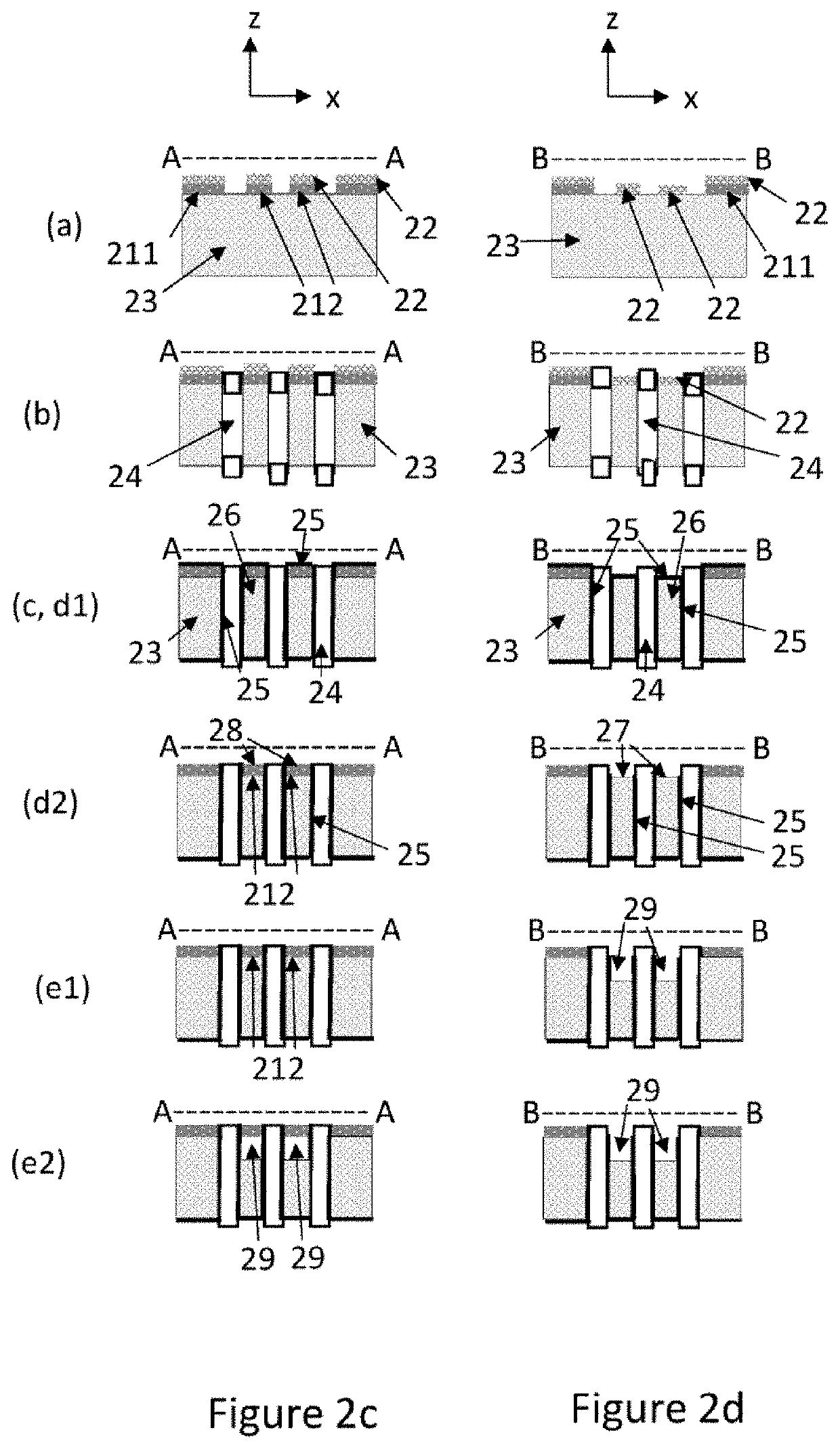

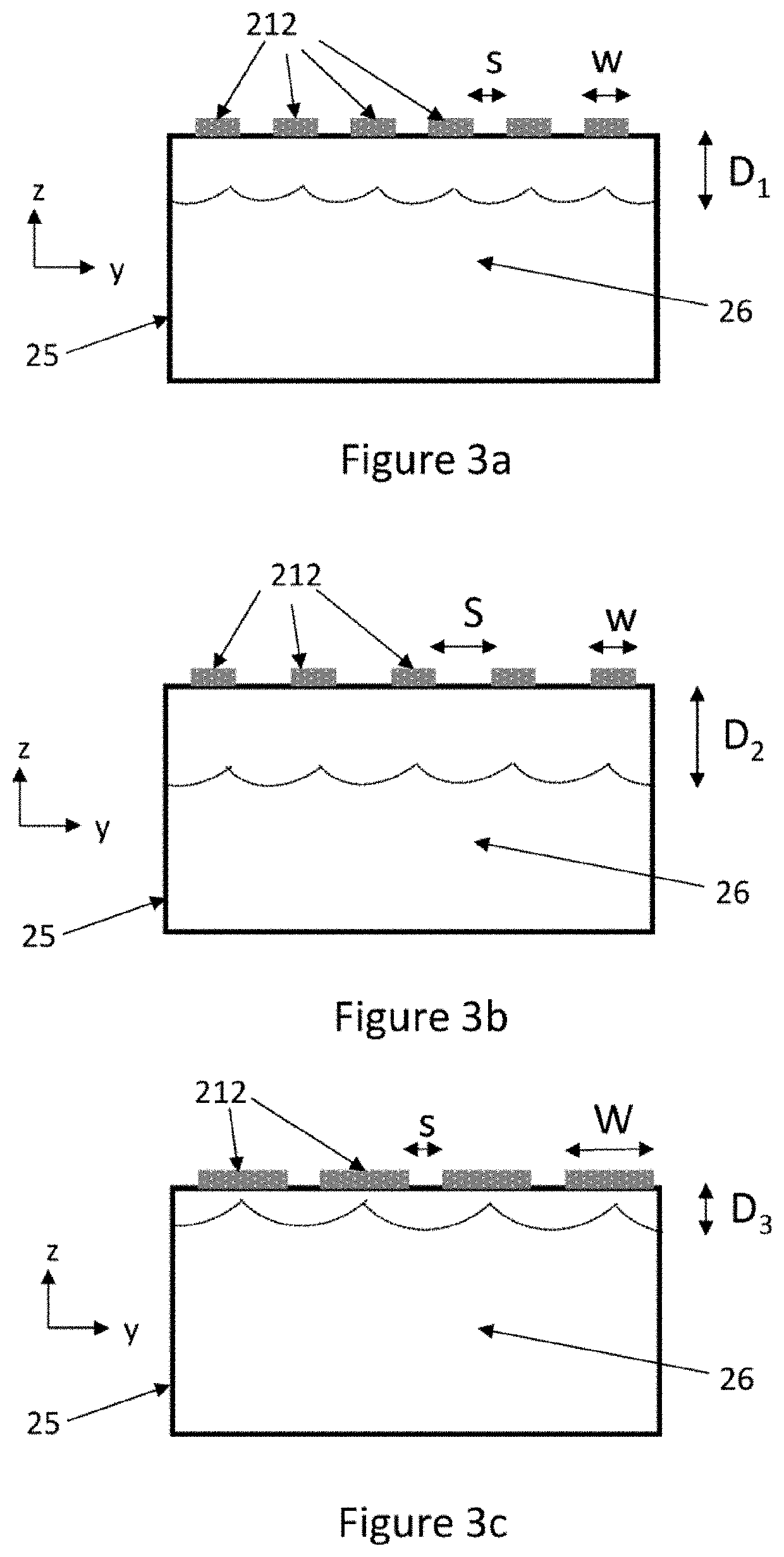

[0023]This disclosure describes a method for manufacturing micromechanical structures in a structural layer of a wafer. The manufactured structures include at least one recess area where the micromechanical structures are vertically recessed in relation to a horizontal face of the structural layer. The method comprises the following steps a-e:[0024]a) depositing and patterning a first etching mask and a second etching mask on the horizontal face of the structural layer, wherein the first etching mask is deposited before the second etching mask, and the second etching mask defines at least one recess area which corresponds to at least one structure which is to be vertically recessed, and the first etching mask defines at least one etch-control area within the at last one recess area, so that each etch-control area is separated from other etch-control areas and extends across the at least one recess area, from one side of said recess area to another side of said recess area,[0025]b) e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com