Low viscosity lubricating oil composition

a lubricating oil and low viscosity technology, applied in the direction of lubricant composition, base materials, additives, etc., can solve the problems of high evaporation loss, increase in oil consumption, and low viscosity of base oils, so as to reduce evaporation loss and improve fuel efficiency of engines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

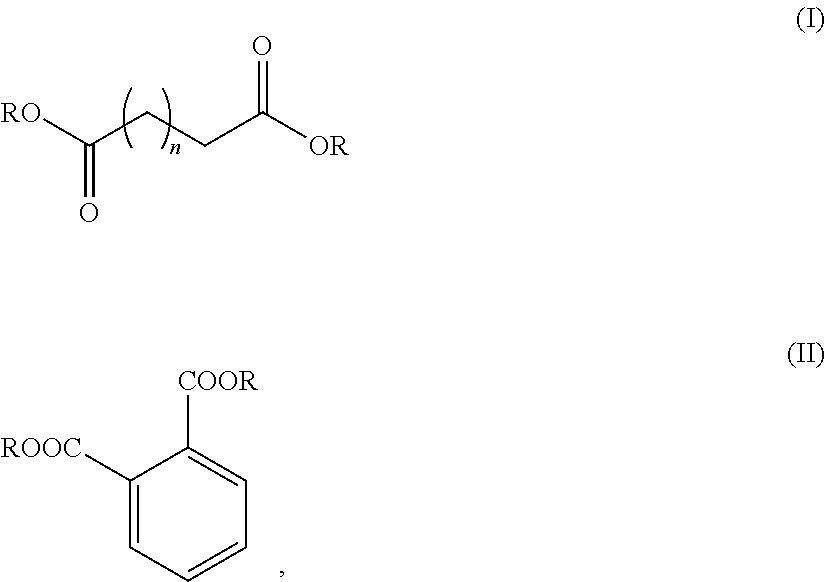

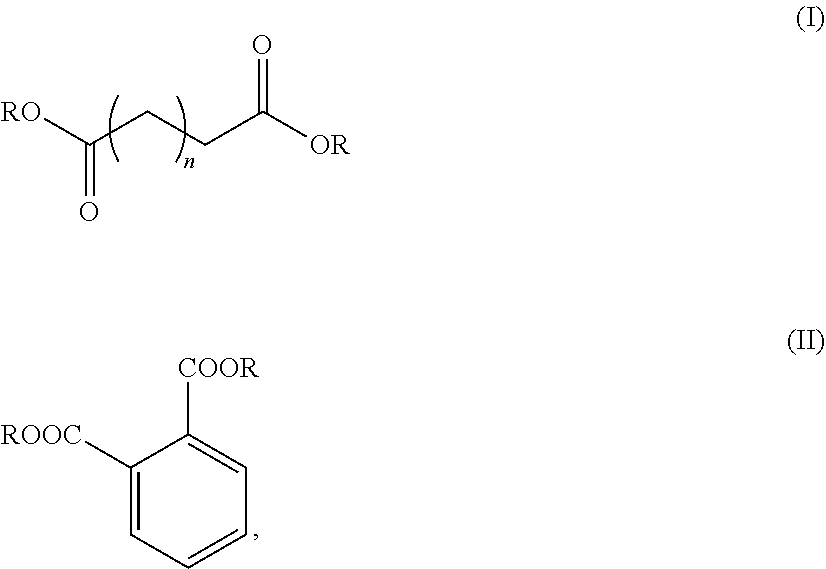

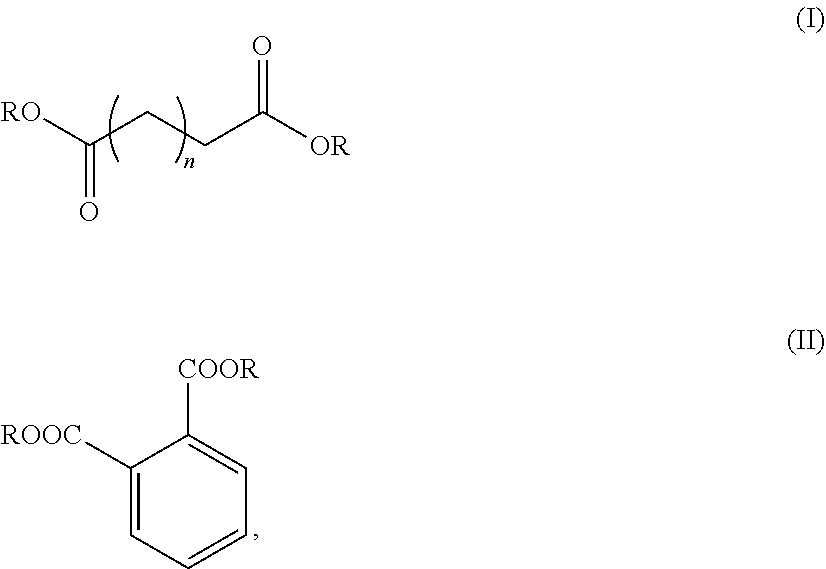

Image

Examples

example 1

[0103]A lubricating oil composition was prepared by adding 98 wt. % of Bis-2-ethylhexyl azelate base oil and 1.59 wt. % based on the concentrate of a borated polyisobutenyl bis-succcinimide dispersant where the number average molecular weight of the polyisobutene is approximately 1300 providing the finished oil with approximately 0.008 wt. % of boron. The formulation had a NOACK of 17.7% and HTHS 80 of 3.73 mPa·s.

example 2

[0104]A lubricating oil composition was prepared by adding 97 wt. % of Bis-2-ethylhexyl azelate base oil and 3 wt. % based on the concentrate of a borated polyisobutenyl bis-succcinimide dispersant where the number average molecular weight of the polyisobutene is approximately 1300 providing the finished oil with approximately 0.019 wt. % of boron. The formulation had a NOACK of 16.4% and HTHS 80 of 4.01 mPa·s.

example 3

[0105]A lubricating oil composition was prepared by adding 48 wt. % of Bis-2-ethylhexyl azelate base oil, 48 wt. % of Group III base oil (KV 100=4.19, VI=125) and 3 wt. % based on the concentrate of a borated polyisobutenyl bis-succcinimide dispersant where the number average molecular weight of the polyisobutene is approximately 1300 providing the finished oil with approximately 0.019 wt. % of boron. The formulation had a NOACK of 15.9% and HTHS 80 of 4.50 mPa·s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com